It has no slurry suction, self-priming, mechanical stirring, wide range of particle sizes that can be processed, and high mineral processing recovery rate.

【Processing Capacity】:0.2~12m3/min

【Effective volume】:0.37~20m3

【Application Environment】:It is suitable for roughing and sweeping operations in various medium and large metal and non-metal concentrators.

15311826613

Click to add WeChatThe JJF flotation machine is a flotation equipment that does not absorb slurry but can self-aspirate. It has large air suction capacity, good dispersion effect, moderate stirring degree, and good mineral particle suspension effect. It can be used alone in the mineral processing plant, or can be used in combination with SF type flotation machine. JJF type is used as a DC tank, the SF type flotation machine is used as a suction tank, and is configured horizontally without pumping.

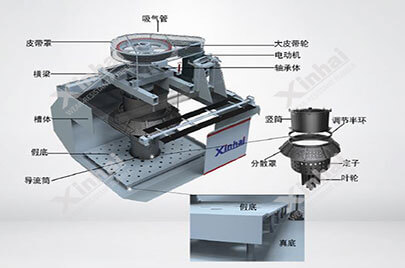

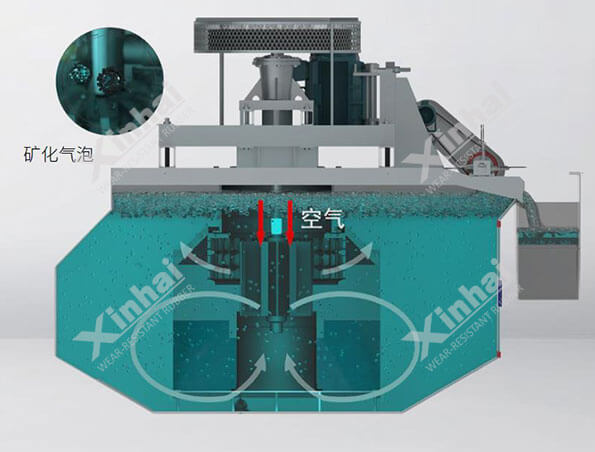

The tank of the Jjf flotation machine adopts a shallow tank design, and the bottom of the tank is equipped with a guide cylinder and a bottom to guide the slurry at the bottom of the tank into the impeller, which can promote the circulation of the slurry in the tank in a fixed direction, thereby ensuring that the slurry is Multiple cycles and multiple aerations increase the chances of sorting and facilitate slurry suspension.

The impeller of the Jjf flotation machine is a star-shaped impeller with radial blades. The impeller is symmetrical up and down and can be used upside down; the height of the stator is lower than the impeller, so the slurry circulation volume is large, which is conducive to the mutual adhesion of slurry, chemicals and air.

The blade area and impeller height of the JJF flotation machine are both large, and its installation depth is shallow, which can not only ensure strong stirring force, but also self-prime enough air (can be within 0.1-1m³ /㎡.min), the impeller speed is slow (line speed is about 6.6m/s), the diameter is small, the speed is low, the energy consumption is small, and the gap with the stator is large, so it can extend the service life of the stator and impeller.

The stator adopts a suspended squirrel cage stator, which can convert the tangential rotating pulp flow generated by the impeller into a radial pulp flow, preventing the pulp from swirling in the flotation tank and promoting the stable formation of the foam layer. Helps the slurry recirculate in the tank. At the same time, a strong shear annular zone is generated between the impeller and the stator, which promotes the formation of small bubbles.

The use of a conical dispersion cover can isolate the vortex generated by the impeller from the foam layer, stabilize the liquid level, and enable the mineralized bubbles to rise evenly with the foam layer, while further dispersing the air and slurry.

The mixing degree is moderate, the solid particles are well suspended and do not sink in the tank, and there is no need to discharge the ore when the machine is stopped.

The structure of JJF flotation machine mainly consists of tank body, suction pipe, belt cover, beam, large pulley, motor, bearing, false bottom (real bottom, home bottom), guide tube (vertical tube, adjusting half ring, dispersion cover, stator, impeller) and other parts.

The working principle of the Jjf flotation machine is that when the blades rotate, vortices are generated in the vertical cylinder and the guide tube. This vortex forms a negative pressure, sucking the air from the inlet pipe, and mixes it with the air sucked in through the guide tube in the impeller and stator area. Slurry mixing. The mixed flow of slurry and air moves in a tangential direction by the impeller, and then is converted into radial motion by the action of the stator and generates a local turbulent flow field. This turbulent flow field helps to mix the air slurry and refine the air bubbles, while making the slurry uniform. Distributed in flotation tank. The mineralized bubbles rise to the foam layer, and the foam product is scraped out from one or both sides.

jjf type flotation machine packaging and delivery

jjf flotation machine installation and commissioning site

jjf type flotation machine at the site of a gold mine beneficiation project

| model | Effective volume (m3) | Processing power(m3/min) | Impeller diameter (mm) | Impeller speed(r.p.m) | Motor power for stirring (kw) | Scraper motor power (kw) | Single tank weight (kg) |

|---|---|---|---|---|---|---|---|

| JJF-4 | 4 | 2.0-4 | 410 | 305 | 11 | 1.5 | 2303 |

| JJF-5 | 5 | 2.0-6 | 410 | 305 | 11 | 1.5 | 2416 |

| JJF-8 | 8 | 4.0-12 | 540 | 233 | 22 | 2.2 | 4507 |

| JJF-10 | 10 | 5.0-10 | 540 | 233 | 22 | 1.5 | 4820 |

| JJF-16 | 16 | 5.0-16 | 700 | 180 | 37 | 1.5 | 7657 |

| JJF-20 | 20 | 5.0-20 | 770 | 180 | 45 | 1.5 | 8505 |