Xinhai high-frequency dehydration screens have complete models and high dehydration efficiency. They are used in mineral processing plants and have high overall cost performance.

[Processing Capacity]:≤250t/h

[Dehydration rate]:More than 50%

[Application Environment]:Can be used for tailings dry discharge, Filtration and dehydration equipment industries such as concentrate dehydration, slurry concentration, chip removal, carbon slurry separation, etc.

15311826613

Click to add WeChatXinhai high-efficiency dehydration screen is particularly suitable for processing fine-grained minerals and can be used with Xinhai cyclones to achieve higher and more complete dehydration efficiency. In addition, the Xinhai dehydration screen has openings on the side of the screen plate, which allows part of the water on the screen to flow out of the pores, improving the dehydration speed and efficiency, and effectively avoiding damage caused by water splashing onto the motor.

The screen plate adopts a thermal stress-free modular screen plate, and its sealing method adopts strip installation form and good sealing effect;

The side protection plates of the dewatering screen are coated with wear-resistant rubber, which can effectively reduce the wear of the side protection plates and reduce the contamination of materials by iron;

There is a low-concentration slurry overflow pipe at the rear, which can speed up the dehydration of the screen body;

The -5°inclination screen surface allows the discharge material on the screen to have a lower moisture content;

The shock-absorbing device is also made of wear-resistant rubber, which has good shock-absorbing effect and can make the screen run more smoothly.

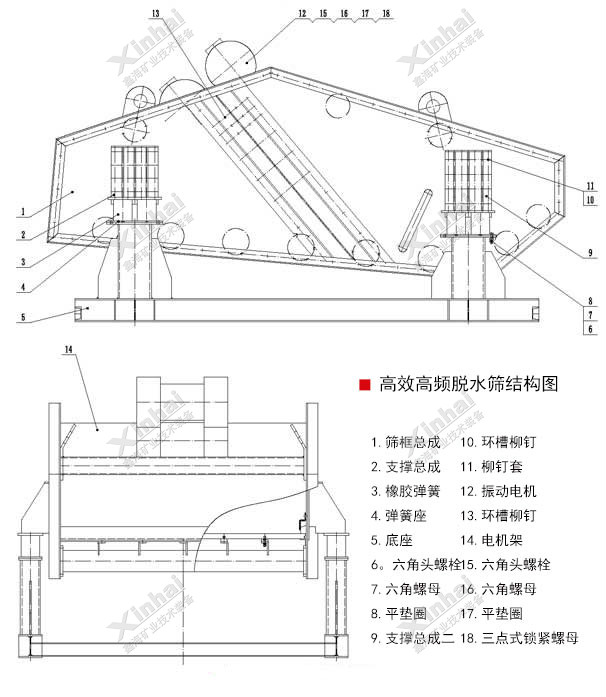

The dewatering screen is mainly composed of a screen box, a vibrator, a support system and a motor.

The Xinhai high-efficiency dewatering screen adopts dual-motor self-synchronization technology, a universal eccentric block, and an adjustable amplitude vibrator. Two independent vibrators run in synchronous and reverse directions, and the centrifugal force generated by the two sets of eccentric masses vibrates along the The component forces in the directions are superimposed and counteracted by the reverse centrifugal force, thus forming a single excited vibration along the vibration direction, causing the screen box to make a reciprocating linear motion.

The picture above is the high-frequency dewatering screen equipment customized by Xinhai Mining for the tailings of a copper-lead-zinc mine. According to the actual situation of mineral processing, Xinhai designed the mineral processing process (including the tailings dry discharge process design) for it. The tailings The process of the ore dry discharge part is: a two-stage concentration and dehydration scheme of concentrator and dehydration screen. The tailings enter the cyclone for one-stage concentration, and the overflow is fed to the concentrator for two-stage concentration. The low flows of the two stages of concentration are fed to the dehydration screen. The dehydration process is carried out to realize dry discharge of tailings, while the overflow water from the thickener is returned for reuse.

| Specifications Model | Lower 30°% solid volume feed concentration | Single Motor power (KW)×quantity (units) | ||||||

|---|---|---|---|---|---|---|---|---|

| Fine coal theoretically -0.5+0.1(mm) specific gravity 1.5 | Coarse sand is about -5(mm)100%, -0.6(mm)50%, specific gravity 2.7 | Fine sand 90% -1(mm) Specific gravity 2.7 | 980 (r/min) | 1460 (r/min) | ||||

| 1460 (r/min) | 980 (r/min) | 1460 (r/min) | 980 (r/min) | 1460 (r/min) | 980 (r/min) | |||

| VD6 | 6~8 | 10 ~13 | 14 | 28 | 10 | 21 | 2 ×2 | |

| VD9 | 9~12 | 15 ~20 | 21 | 42 | 16 | 32 | 3×2 | |

| VD12 | 15 ~19 | 24 ~30 | 33 | 67 | 25 | 50 | 2.6×2 | 4×2 |

| VD15 | 30 ~35 | 50 ~60 | 63 | 125 | 47 | 94 | 2.4×4 | 2.25×4 |

| VD18 | 35~45 | 60 ~80 | 77 | 153 | 57 | 115 | 3.7×4 | |

| VD21 | — | 85~100 | — | 225 | — | 164 | 15 | — |

| VD24 | 95~110 | 250 | 190 | |||||