The technical feature of the centrifuge is centrifugal flow film mineral processing, mainly because centrifugal force replaces gravity and flow film mineral processing in the centrifugal force field.

[Production Capacity]:0.25~12t/h

[Application Scope]:Centrifugal concentrators are generally used in roughing and concentrators with large specific gravity differences.

15311826613

Click to add WeChatThe Xinhai centrifugal concentrator uses centrifugal force instead of gravity to strengthen the separation effect; and the centrifugal force of the ore particles deposited on the drum wall is 9 times greater than the gravity of the ore particles deposited on the ordinary chute bed.

The staggered motion of liquid flows with a large speed difference in the centrifuge causes the ore particles to be strongly affected;

The speed difference of this staggered motion is large, which is 10 times greater than the flow rate of the slurry in an ordinary chute. More than times. The flow rate of the slurry in the chute is 0.3~0.5 m/s, while the linear speed of the drum wall is 20 m/s;

In the centrifuge, the larger the specific gravity of the ore particles, the closer they are to the drum wall, and their rotational speed is the same as that of the drum wall. The greater the centrifugal force, the smaller the force exerted by the liquid flow toward the ore discharge end. On the contrary, the smaller the specific gravity, the greater the effect on the surface of the liquid flow that lags behind the drum wall. The lower the rotation speed, the smaller the centrifugal force. The smaller the specific gravity, the smaller the centrifugal force. The greater the force of the flowing liquid, the easier it is to be discharged to the ore discharge end.

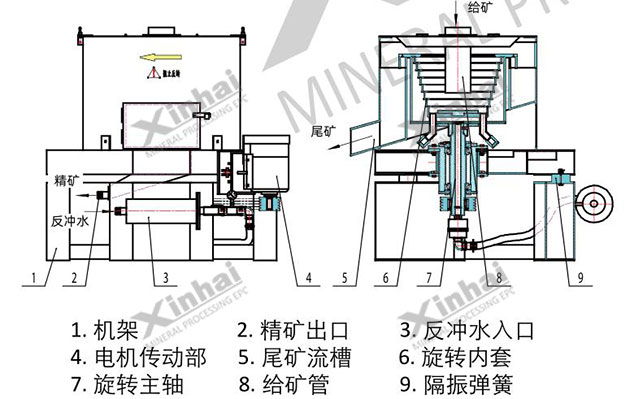

The structure of the centrifugal concentrator is mainly composed of a rotating drum, a chassis, an ore receiving trough, a protective cover, an ore feeding bucket, an ore dividing bucket, an ore feeding nozzle, an ore flushing nozzle, a transmission mechanism and a control mechanism.

Among them, the drum is a hollow truncated cone, which plays the role of selection; the inclination angle of the drum wall is roughly selected as degrees, and the selected angle is degrees. The big head of the drum is used. A screw is used for the flange and a washer is added to the chassis connection, thus forming a millimeter circumferential ore discharge gap between the drum and the chassis. The produced concentrate and tailings are discharged into the ore receiving trough at different times, and are discharged from the lower ore discharge port into the ore distribution hopper. . The ore dividing bucket swings regularly to make the concentrate and tailings flow into the concentrate ditch and the tailings ditch respectively.

The slurry is equipped with two ore feeding hoppers and is fed into the drum in the direction of rotation. When the slurry encounters the rotating drum wall, under the action of centrifugal force, the ore particles with a specific gravity are brought close to the drum wall. The slurry flows towards the ore discharge gap due to the axial component force. At the same time, the tangential high speed of the drum wall meets the slurry. Axial flow of slurry. The mineral particles close to the drum wall are forced to move. The mineral particles with large specific gravity drill to the bottom and are deposited on the drum wall as concentrate due to the small effect of the axial liquid flow. The mineral particles with small specific gravity, especially light and fine, are deposited on the surface. Affected by the axial liquid flow, it is discharged into the tailings ditch.

If you want to know the detailed equipment parameters of Xinhai gravity separation centrifugal concentrator, or more Xinhai mineral processing equipment, please contact Xinhai customer service hotline -15311826613!