Self-priming slurry, self-priming, mechanical stirring, good slurry circulation, stable liquid level, and high sorting efficiency.

【Processing Capacity】:0.1~20m3/min

[Particle size range]:-200目占45-90%

[Slurry concentration]:<45%

【Application Environment】:It is used for sorting various metal and non-metal minerals. It is suitable for medium and small-scale mineral processing plants. Its self-priming air volume can reach 1.2m3/m2·min。

15311826613

Click to add WeChatGF type flotation machine is a mechanical stirring flotation machine that self-primes air and slurry. The self-priming air volume can reach 1.2m3/m2·min, with large aeration volume, high air dispersion, high sorting efficiency and good slurry circulation. , the recovery rate can be significantly improved for minerals with high slurry concentration, heavy mineral specific proportions, and coarse or fine particle sizes.

The impeller is the most important part of the GF flotation machine. It is responsible for stirring and circulating the slurry, sucking in and dispersing air. This component is an impeller composed of a dividing plate, upper blades and lower blades. While sucking in air, it ensures that the mineral particles are fully suspended and the bubbles are completely distributed in the entire slurry, so that the flotation tank has a higher flotation probability.

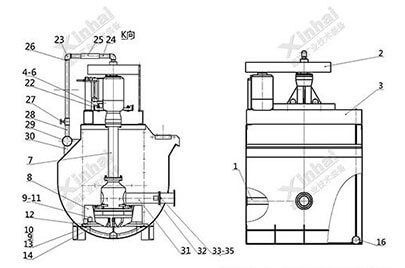

GF flotation machine is mainly composed of impeller, stator, main shaft, central cylinder, tank body, suction pipe, bearing body, motor, etc.

When the impeller of the GF flotation machine rotates, a negative pressure is formed in the center area of the blades on the impeller. Under the action of this negative pressure, air is sucked, the ore is fed, and the ore is extracted from the foam. Air and slurry enter between the upper blades at the same time, and at the same time, the lower blades suck the slurry from the bottom of the tank into the space between the lower blades. The upper and lower slurry flows merge in the middle of the impeller blade and continue to move toward the periphery of the impeller. The slurry-air mixture leaves the impeller and flows through the cover plate. It is stabilized and directed by the angled blades of the cover plate and then enters the main slurry in the tank. The mineralized bubbles rise to the surface to form a foam layer. Part of the slurry in the tank returns to the lower blade of the impeller for recycling, and the other part enters the next tank for re-separation or drainage.

gf flotation machine is being installed on site

Xinhai Mining gf flotation machine is being packaged and shipped

Application site of Xinhai Mining gf flotation machine

| Model specifications | Volume | Tank size Length×width×height | Motor power | Production capacity | Air suction volume | Scraper power Machine power | Weight |

| m3 | m×m×m | kw | m3/min | m3/m2.min | kw | kg | |

| 0.35 | 0.35 | 0.7×0.7×0.73 | 1.5 | 0.1-0.2 | 1.2 | 0.75 | 470 |

| GF-0.7 | 0.7 | 0.9×0.9×0.9 | 3.0 | 0.1-0.4 | 1.2 | 1.1 | 932 |

| GF-1.1 | 1.1 | 1.1×1.1×1.0 | 5.0 | 0.2-0.5 | 1.2 | 1.1 | 1370 |

| GF-2 | 2 | 1.40×1.40×1.15 | 7.5 | 0.3-1.0 | 1.2 | 1.5 | 1750 |

| GF-3 | 3 | 1.50×1.85×1.20 | 11 | 0.5-1.5 | 1.2 | 1.5 | 2230 |

| GF-4 | 4 | 1.60×2.15×1.25 | 15 | 0.5-2.0 | 1.2 | 1.5 | 2585 |

| GF-6 | 6 | 2.0×2.5×1.3 | 22 | 1.0-3.0 | 1.2 | 1.5 | 3300 |

| GF-8 | 8 | 2.2×2.9×1.4 | 30 | 1.0-4.0 | 1.2 | 1.5 | 4130 |

| GF-10 | 10 | 2.2×2.9×1.7 | 30 | 2.0-6.0 | 1.2 | 1.5 | 4500 |

| GF-16 | 16 | 2.85×3.80×1.70 | 45 | 3.0-8.0 | 1.2 | 2.2 | 8320 |

| GF-20 | 20 | 2.85×3.80×2.00 | 45 | 4.0-10.0 | 1.2 | 2.2 | 8670 |

| GF-24 | 24 | 3.15×4.15×2.00 | 55 | 5.0-12.0 | 1.2 | 2.2 | 8970 |

| GF-28 | 28 | 3.15×4.15×2.30 | 55 | 5.0-14.0 | 1.2 | 2.2 | 9480 |

| GF-42 | 42 | 3.60×4.80×2.65 | 75 | 8.0-20.0 | 1.2 | 3 | 19400 |