The gold mud selected for the high-efficiency desorption electrolysis system is of high grade, does not require reverse electrolysis, and is easy to extract.

【Processing Capacity】:≥3.5kg/t

【Effective volume】:PH>13.5

[Applicable scale]:1500~3000t/d

【Application Environment】:Cyanidation process is used in alchemy to extract solid gold from gold-laden carbon.

15311826613

Click to add WeChatXinhai Mining Production high-efficiency desorption electrolysis system is non-toxic, cyanide-free, low-cost, and less polluting. It has triple protection measures of the system own intelligence, automatic pressure-limiting pressure release mechanism, and insurance safety valve.

Under the conditions of high temperature of 150℃ and high pressure of 0.5MPa, the desorption rate of the desorption electrolysis system can reach more than 98%.

The temperature of desorption and electrolysis is the same, and no heat exchange is required. Due to the fast operation, the power consumption is 1/4 to 1/2 of the conventional system;

The non-toxic desorption combination agent contains Carbon activator regenerates charcoal. Depleted charcoal does not require fire regeneration, thus saving charcoal regeneration costs.

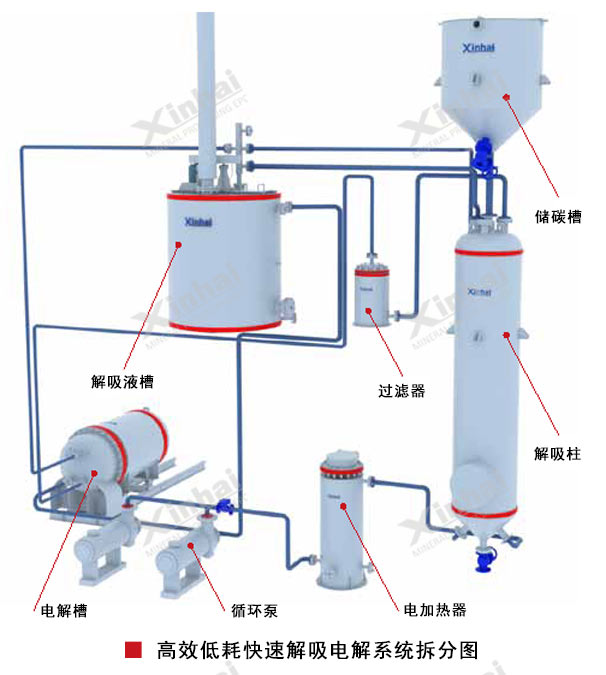

The desorption electrolysis system consists of a desorption liquid tank, an electrolytic tank, a circulation pump, an electric heater, a filter, a desorption column, a carbon storage tank and other parts.

The working principle of analytical electrolysis is to add anions that are easily adsorbed by activated carbon into the desorption system to replace Au(CN)2-. The precious liquid obtained by desorbing gold-loaded carbon is recovered through ionization method to obtain solid gold.

Xinhai’s high-efficiency, low-consumption rapid desorption electrolysis system is mainly composed of two parts: desorption and electrolysis. The processes of desorption and electrolysis are separated, so that the solvent is carried out in the comprehensive desorption tower, and the electrolysis of your liquid is carried out in an independent It is completed in the electrolytic cell. The four processes of solvent desorption, precious liquid heating, solvent condensation and solvent recovery are concentrated in the comprehensive desorption tower, and the precious liquid obtained after desorbing the gold-loaded carbon from the solvent vapor is introduced into an independently set up electrolyzer through a pipeline. Electrolysis is carried out in the tank to obtain crude gold, which is then purified to obtain finished gold.

Xinhai desorption electrolysis system application site diagram

Xinhai desorption electrolysis system application site diagram

Xinhai desorption electrolysis system application site diagram

| Model | Applicable scale | System equipment details | System instrumentation details | Operating parameters | |

|---|---|---|---|---|---|

| Mine size(t/d) | Raw ore grade(g/t) | ||||

| GJD-200 | < 150 | 2-8 | S1 desorption column S2 filter S3 electrolyzer S4 circulation pump S5 electric heater S6 carbon injector S7 air compressor S8 desorption liquid tank S9 clean water pump S10 acid storage tank S11 magnetic pump S12 carbon storage tank S15 control cabinet S16 silicon rectifier cabinet S17 pickling mixing tank | B1 resistance remote transmission diaphragm pressure gauge B1 pressure indication regulator B2 diaphragm pressure gauge B3 vortex flowmeter B3 flow totalizer B4 Thermal Thermometer B5 Temperature Sensor B5 Temperature Indication Regulator B6 Diaphragm Pressure Gauge B7 Liquid Level Gauge B9 Temperature Sensor B9 Temperature Indicator Regulator | Desorption solution: PH > 13.5 Use batch: unlimited times Start of electrolysis: 100-110 °C< br/>End of electrolysis: 150 °C Electrolysis current: 350-1250 A Electrolysis voltage: 2-4 V Pressure at 150°C: Desorption column Upper part: 0.50 -0.57 MPa Electrolytic cell:0.45-0.52 MPa |

| GJD-300 | 150-300 | ||||

| GJD-450 | |||||

| GJD-500 | 300-500 | ||||

| GJD-600 | |||||

| GJD-750 | |||||

| GJD-1000 | 500-1000 | ||||

| GJD-1200 | |||||

| GJD-1500 | |||||

| GJD-1800 | |||||

| GJD-2000 | 1000-2000 | 2-20 | |||

| GJD-2500 | |||||

| GJD-3000 | |||||

| GJD-3500 | 2000-3000 | ||||

| GJD-4000 | |||||

| GJD-5000 | |||||

| Special type | > 3000 | ||||