15311826613

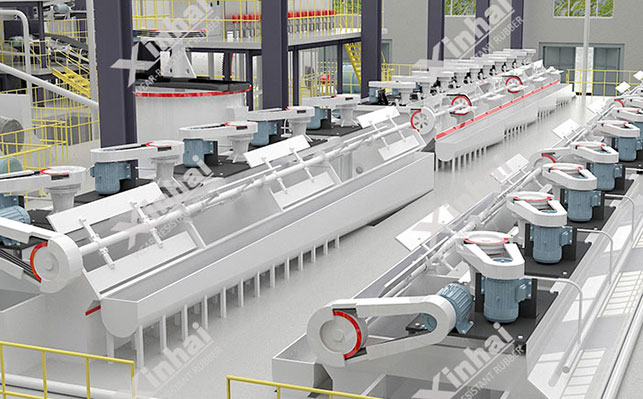

Click to add WeChatWhat is a flotation machine? The flotation machine is a kind of equipment used in mineral processing in mines. Useful minerals emerge from the finely ground ore particles, or gangue minerals are reversely flotated to complete the separation operation.

In flotation operation, before the slurry enters the flotation machine, it needs to be stirred first. Tank, add medicine and stir, so that the ore slurry and medicine are fully mixed and then enter the flotation machine. The stirring of the impeller of the flotation machine causes centrifugal force to generate negative pressure in the impeller cavity. At the same time, air is sucked in to ensure that the slurry and gas are fully dispersed in the cavity. After mixing, the slurry that reacts with the medicine will adhere to the bubbles and float to the surface of the flotation tank, where it will be scraped out by the scraper to complete the flotation operation.

At present, the common types of flotation machines in mineral processing plants are mainly mechanical agitation flotation machines and inflatable agitation flotation machines. Flotation columns are occasionally seen. equipment.

The mechanical agitation flotation machine mainly relies on a mechanical agitator ( It can realize the aeration and mixing of the slurry, and can self-prime air and slurry without the need for external aeration devices. The return of the middle ore does not require pump transmission. Common ones such as sf flotation machine, jjf flotation machine, bf flotation machine are all mechanical agitation flotation machines.

The inflatable stirrer flotation machine is a flotation machine that relies on external air supply. Its stirring device only plays the role of stirring (slurry). Inflating requires an external blower device. Common ones such as XCF flotation machine, KYF flotation machine, etc. belong to this type of equipment.

The flotation column is also an inflatable flotation machine. This type of flotation The concentrator does not have mechanical stirring devices and transmission parts. The slurry needs to be transported by a pump and the air is supplied by an external blower device. When working, the slurry is fed into the flotation machine from the inlet, and bubbles are generated through the internal or external bubble generator, and then the minerals are attached. As the bubbles rise to the foam layer, they are washed with water to form concentrate.

With the continuous development of science and technology, the development speed of the mining industry has accelerated, accelerating the development of mining equipment, including flotation machines, which can It completes the separation of most minerals and is the main mineral processing equipment of the mine mineral processing plant. Nowadays, the flotation machine market is developing rapidly, various flotation machines are emerging in endlessly, and there are more and more flotation machine manufacturers, and the choice has become a problem for people. How to choose? How to choose? Who to choose?

Xinhai Mining Equipment has more than 20 years of experience in producing flotation machines and can produce most of the flotation machine equipment used in mineral processing plants, such as xcf, kyf, sf, jjf, xjb, bf, xjb, xjc and other equipment. Xinhai not only produces flotation machines, but also innovates and develops new flotation machines such as xcf/kyf flotation units and flotation machine impeller components to improve the working efficiency of flotation machines.

In addition, Xinhai Mining can also conduct mineral processing tests based on the actual conditions of the mineral processing plant. According to the test results, Customized mineral processing technology plan, Ore processing construction plan, Configuration of suitable flotation machine equipment or Complete set of mineral processing equipment strong>andInstallation and commissioning plan and construction of mineral processing plant, etc.

Flotation plant design

Construction and installation of flotation machine plant

Nowadays, various industries are developing one-stop service. Xinhai Mining always encounters various problems during the project process, so it launched One-stop mineral processing service - Mining full industry chain service avoids various disputes and blame-shifting, and Xinhai is responsible for it from start to finish.

At present, there are many manufacturers of flotation machines, and there are also middlemen, so the quotations of flotation machines also vary. In addition,the production and manufacturing costs of flotation machines also vary. Their material selection, manufacturing process, labor costs, etc. are all different, so the quotations given are also different. Therefore, the editor recommends contacting the flotation machine manufacturer directly. Compare prices and choose the one with the best price.