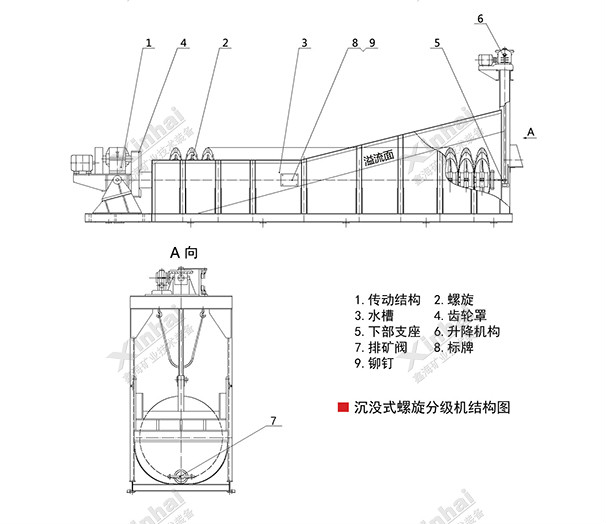

Xinhai spiral classifiers are divided into two types: high weir type and submersible type. The difference between the two is that one of the overflow end spirals will be completely immersed under the page.

【Processing Capacity】:10~1785t/d/50~1410t/d

[Feeding particle size]:≤25mm

[Discharge particle size]:≤0.2mm

【Features】:The spiral classifier produced by Xinhai adds an automatic sand return lifting device at the sand return end, which improves the operating efficiency of the ball mill.

15311826613

Click to add WeChatThe processing capacity range of the Gaoyan spiral classifier is 10~1785t/d, which is generally suitable for coarse particle classification; the processing capacity range of the submersible spiral classifier is 50~1410t/d, and it is mainly suitable for overflow particle size 0.15~0.07 mm fine-grained ore classification.

Each ton of ore can generally save 1 to 1.5 degrees of electricity;

Avoid frequent maintenance of the ladle head;

Slow down the damage to the ball mill , Uneven impact of the pinion.

The structure of spiral classifier equipment generally consists of: water tank, spiral, bottom support seat, ore discharge valve, gear cover, lifting mechanism, etc.

The working principle of the Gaoyan spiral classifier:The finely ground slurry is fed into the water tank from the feed port located in the middle of the settling area. Below the inclined water tank is the slurry classification and settling area. The spiral rotates at low speed, and the slurry is It plays a stirring role to suspend fine particles to the top and flow to the overflow weir to overflow. The coarse particles sink to the bottom of the tank and are conveyed by the screw to the discharge port and discharged as return sand. The position of the overflow weir is higher than the bearing center at the lower end of the spiral shaft and lower than the upper edge of the spiral at the overflow end.

The working principle of the submersible spiral classifier:With the help of the different size and specific gravity of solid particles, their settling speed in the liquid is also different. Therefore, the fine ore particles float in the water and form an overflow, while the coarse ore particles sink in the liquid. The bottom of the tank is pushed up by a spiral and discharged to the upper part for mechanical classification.

| type | Model | Spiral speed (r/min) | Based on sand return processing capacity (t/d) | Based on overflow processing capacity (t/d) | Spiral diameter (mm) | Spiral length (mm) | Sink slope | Transmission motor Model | Transmission Motor power(KW) | Boost motor Model | Boost motor power (kW) | Weight(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| High weir type single spiral | FLG-300 | 7.7 | 30 ~80 | 10 ~30 | φ300 | 3900 | 14 ~18 | Y100L1-4 | 2.2 | Manual | — | 668 |

| FLG-500 | 8 | 145~260 | 21 ~75 | φ500 | 4390 | Y112M-6 | 1600 | |||||

| FLG-750 | 7.8 | 100~445 | 31~165 | φ750 | 5500 | Y132S-6 | 3 | 2716 | ||||

| FLG-1000 | 6.7 | 473~1026 | 85 | φ1000 | 6556 | Y132M2-6 | 5.5 | 4000 | ||||

| FLG-1200 | 5,6,7 | 1145~1600 | 150 | φ1200 | 6500 | Y132M2-6 | 5.5 | Y90L-4 | 1.5 | 7943 | ||

| FLG-1500 | 2.5,4,6 | 1140~2730 | 235 | φ1500 | 8265 | Y160M-6 | 7.5 | Y100L1-4 | 2.2 | 11827 | ||

| FLG-2000 | 3.6,5.5 | 3240~5940 | 400 | φ2000 | 8700 | Y160L-6/4 | 11,15 | Y100L2-4 | 3 | 20814 | ||

| FLG-2400 | 3.6 | 6800 | 580 | φ2400 | 9130 | Y200L2-6 | 22 | Y112M-4 | 4 | 24194 | ||

| FLG-3000 | 3.2 | 11625 | 890 | φ3000 | 12500 | Y200L-4 | 30 | Y112M-4 | 4 | 42188 | ||

| High weir double helix | 2FLG-1200 | 5,6,7 | 2290~3200 | 310 | φ1200 | 6500 | Y132M2-6 | 5.5X2 | Y90L1-4 | 1.5X2 | 15840 | |

| 2FLG-1500 | 2.5,4,6 | 2240~5360 | 460 | φ1500 | 8230 | Y160M-6 | 7.5X2 | Y100L1-4 | 2.2X2 | 22903 | ||

| 2FLG-2000 | 3.6,5.5 | 6400~10800 | 750 | φ2000 | 8400 | Y160L-4 | 15X2 | Y100L2-4 | 3.0X2 | 34621 | ||

| 2FLG-2400 | 3.63 | 13600 | 1160 | φ2400 | 9130 | Y200L2-6 | 22X2 | Y112M-4 | 4X2 | 42460 | ||

| 2FLG-3000 | 3.2 | 23300 | 1785 | φ3000 | 12500 | Y200L-4 | 30X2 | Y112M-4 | 4.0X2 | 73030 |