15311826613

Click to add WeChatBauxite is the main mineral resource for obtaining aluminum. In my country, although bauxite resources are abundant, they mostly exist in the form of diaspore with high silicon, high aluminum and low aluminum-silicon ratio. In order to effectively improve the aluminum grade, desiliconization treatment is required first. This article will introduce several common bauxite desiliconization processes.

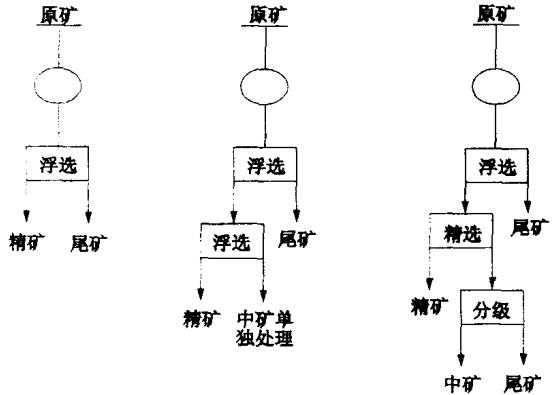

The one-time fine grinding positive flotation process often adopts the secondary roughing and one-time concentrating process. With the continuous optimization of the flotation operation process structure, multiple concentrating times can be adopted, and the middling ore in the concentrating operation has two processes: separate flotation and middling classification.

In this beneficiation method, since fine grinding makes the concentrate particle size finer, and the minerals are heavily muddied, which affects the flotation separation effect, the concentrate aluminum-silicon ratio is low, so there is currently little research on this process, but some process structures of flotation operations have reference value for other processes.

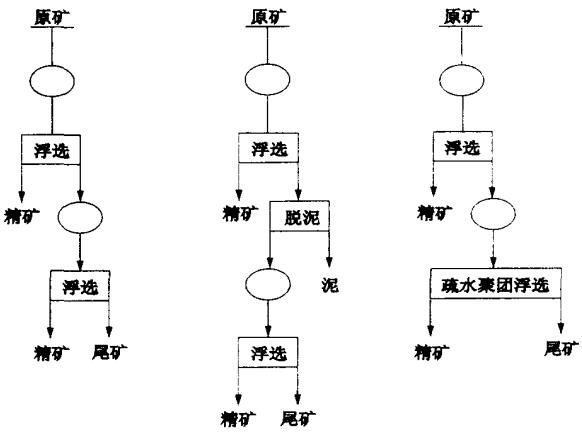

The stage grinding stage selection process is a new type of bauxite positive flotation desiliconization process, and its process flow is to produce part of the concentrate by coarse grinding and flotation, and the first stage flotation tailings are re-grinded and re-selected. In addition, based on the conventional process, the two-stage grinding pre-desiliconization process and the two-stage selective hydrophobic agglomeration process have been developed.

Two-stage grinding pre-desiliconization process: According to the nature of the gangue being easy to be muddy, desiliconization is carried out before the second-stage grinding to reduce the impact of ore mud on flotation and improve the concentration and grinding efficiency of the regrinding operation.

Two-stage selective hydrophobic agglomeration process: It is to introduce mechanical energy to make hydrophobic fine particles agglomerate to increase the apparent size of the recovery object, improve the flotation kinetic behavior of fine particles, and then improve the recovery rate of aluminum concentrate.

Although this process has achieved coarse grinding and selection, breaking through the situation of fine grinding and sorting of bauxite, its process is relatively complicated.

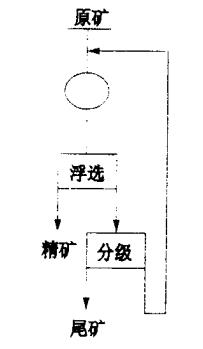

The stage grinding and one-time selection process is a method of coarse grinding and flotation of the original ore, classification of flotation tailings, return of coarse particles for regrinding and reselection, and fine particles as the final tailings. This process has good sorting indicators, stable and reliable operation, and strong adaptability.

The classification-flotation process is to obtain a part of the coarse-grained concentrate by classification before the flotation operation to reduce the amount of ore and reagent consumption in the flotation operation. However, the aluminum-silicon ratio of the coarse-grained concentrate is low, and its yield requires strict control, the production indicators are prone to fluctuations, and the adaptability is poor. For example, when the aluminum-silicon ratio of the original ore is lower than 5, the aluminum-silicon ratio of the coarse particles is only about 6, which affects the aluminum-silicon ratio of the total concentrate. In addition, too coarse particles are easy to enter the concentrate.

On the surface, the flotation-classification process interchanges the classification and flotation operations of the classification-flotation process, but in fact, the coarse particles still need to be flotated, so this method consumes a lot of reagents.

The above is an introduction to the common desiliconization process of bauxite. In the actual beneficiation process, how to effectively desiliconize depends on the silicon content of the bauxite and its ore properties. Therefore, it is recommended to conduct ore dressing tests. Through experimental analysis and design of suitable bauxite desiliconization process, an ideal return on investment has been obtained.