15311826613

Click to add WeChatThe raw materials used in the titanium industry are mainly ilmenite (accounting for 85~90%) and rutile (accounting for 5~10%), and ilmenite is produced in placer and vanadium-titanium magnetite. Vanadium-titanium magnetite is an important mineral resource for obtaining titanium in my country. Below we take a certain vanadium-titanium magnetite as an example to introduce its ore dressing process plan. (Recommend: Hematite beneficiation, Magnetite beneficiation)

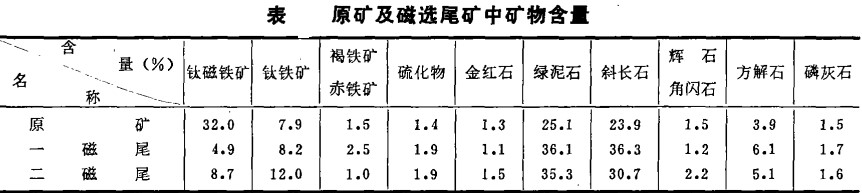

A certain vanadium-titanium magnetite is a paragenetic ore containing valuable metals such as iron, vanadium, titanium, cobalt, nickel, and copper. Its main metal minerals are titanomagnetite and ilmenite, as well as a small amount of pyrite, pyrrhotite, hematite, limonite, anatase, rutile, etc. The gangue minerals are mainly plagioclase, chlorite, and a small amount of calcite, apatite, hornblende, etc. The main metal minerals in the ore are unevenly distributed.

The selection of the beneficiation process is mainly based on the chemical composition, physical and physicochemical properties of the selected minerals and their particle size distribution characteristics. From the above data, it can be seen that the physical properties and particle size distribution characteristics of ilmenite and sulfide are different. This diversity of properties that can be used for separation will lead to the diversity of titanium selection processes. Finally, through the analysis of ore dressing test, a gravity separation-magnetic separation-flotation process was designed for it.

Gravity separation: Before flotation, hydraulic classifiers and spiral classifiers are used to pre-treat the coarse particles by gravity separation. The main purpose is to improve the flotation grade and reduce the consumption of drugs.

Magnetic separation: The strong magnetic separation process is adopted, and the φ2000mm ring permanent magnetic wet strong magnetic separator (field strength 7000 Oersted) is used to discard 60~70% of the tailings, which effectively improves the titanium flotation grade.

Floatation: Sulfuric acid, sodium fluorosilicate, sodium oxysilicate, oxidized paraffin soap, kerosene, etc. are used as ore reagents for flotation, and finally qualified titanium concentrate is obtained.

The above is an introduction to a certain original ilmenite ore dressing process process. In actual ore dressing plants, due to the differences in the properties of titanium ore, the ore dressing process is also different. Therefore, it is recommended to conduct ore dressing tests. By analyzing and designing a suitable titanium ore dressing process plan, an ideal return on investment has been obtained.