15311826613

Click to add WeChatThe fluorite mineral resources I have experienced are very rich and widely distributed, but high-grade fluorite is rare and often coexists with minerals such as quartz, calcite, barite, and kaolinite. In terms of ore dressing methods, flotation is often used as the main method, supplemented by gravity separation. Gravity separation is used to separate coarse particles to obtain coarse fluorite concentrate, while flotation separation is used to separate fine fluorite.

In the flotation process, the selection of collectors is the key. Whether fluorite particles can be well collected is the key to improving the quality of fluorite concentrate. Therefore, this article will focus on the types of fluorite flotation collectors. Common fluorite collectors include fatty acids, modified fatty acids, combined collectors, and new collectors.

The fatty acid collectors for fluorite flotation are mainly oleic acid, which has a wide source and low price, but has poor selectivity and is not resistant to hard water, poor water solubility and low temperature. When used, the slurry usually needs to be heated. In the flotation of fluorite, oleic acid is used as a collector and sodium silicate as a depressant to obtain a better grade of fluorite concentrate.

The modified fatty acid collectors used for fluorite include sodium oleate, HS series collectors, and MG-2 collectors.

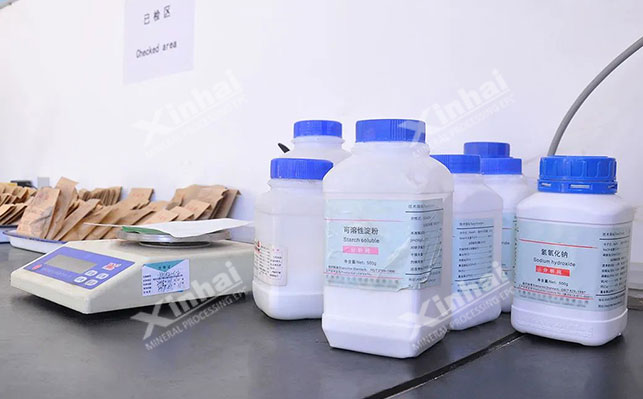

Sodium oleate: is produced by saponification reaction of oleic acid and sodium hydroxide. It dissolves in hot water and can be completely dissociated into ions. It has a certain resistance to low temperatures. Sodium oleate can be used as a collector to obtain relatively ideal separation indicators when selecting calcite, quartz-barite, phlogopite and other fluorite ores.

HS series collector:This collector is an anionic collector, easy to ionize, weakly alkaline in water, and has strong dispersion ability in water. The agent has good low temperature resistance. Generally, it is used as a fluorite collector under acidic conditions.

MG-2 collector:Its chemical composition is α-peroxyhydroxy fatty acid. When MG-2 is used as a collector and water glass and tannin are used as inhibitors, good separation indicators can be obtained for the flotation of quartz-calcite fluorite ores.

Usually when the collection capacity of a single collector cannot meet the requirements, multiple different types of collectors will be mixed to form a combined collector to improve the collection capacity. Common fluorite combined collectors include XL-2, KY-108 and oleic acid + oxidized paraffin soap.

XL-2 collector: is a fatty acid anionic collector with good dispersibility and strong low temperature resistance. It can perform well at an ambient temperature of above 10°C.

KY-108 collector: It is composed of oleic acid and hydroxamic acid, and has better collection performance for fluorite than single oleic acid. Using sodium carbonate and water glass as adjusters and KY-108 as collector to select quartz fluorite, ideal flotation index can be obtained.

Oleic acid + oxidized paraffin soap collector: For quartz fluorite, this reagent combination can effectively reduce the content of silicon dioxide in fluorite concentrate, and the selection index is better than using these two reagents alone.

6RO-12 collector: Its structural formula is RC(O)-NH(CH2)5COOH. Compared with oleic acid and oxidized paraffin soap, this agent has better adaptability and low temperature resistance. When 6RO-12 is used as a collector and TXD as a depressant, good fluorite concentrate can be obtained.

YSB-2 collector: It is an anionic collector, which is made of saponified modified fatty acid salt and compounded with sodium dodecylbenzene sulfonate. It has good solubility, good low temperature resistance and high flotation recovery rate.

BK410 collector: is a liquid that is easily dispersed in water, has good low-temperature fluidity, low viscosity, and has stronger dispersibility and better selectivity than oleic acid. When treating quartz-calcite type fluorite, better flotation indicators can be obtained.

The above are the commonly used collector types in fluorite flotation operations. In the actual ore dressing process, how to choose the reagent needs to be determined based on the ore dressing test analysis. Not only the type of use, but also the amount of use needs to be determined. The correct selection of reagents is the key to high flotation efficiency. Therefore, it is necessary to conduct ore dressing test analysis to determine the appropriate fluorite ore flotation process and suitable flotation reagents.