15311826613

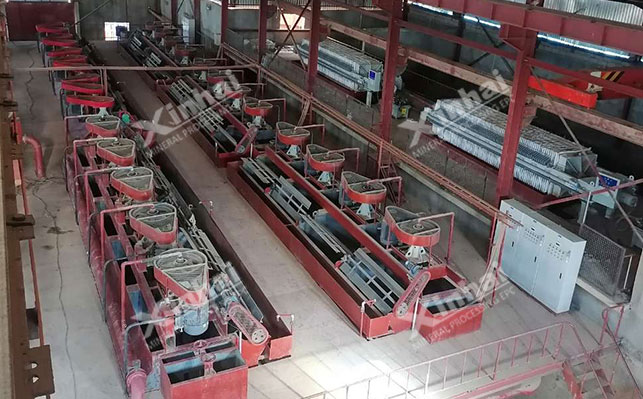

Click to add WeChatThe XJM type flotation machine also has the XJM-S type, which is a new type of flotation machine equipment that has been upgraded on the original basis. It is used in mineral processing plants. , this type of flotation machine is suitable for various metal and non-metallic minerals, and can sort slimes below 0.5mm. So what types of XJM flotation machines are there, and how to select them when used in mineral processing plants? Let’s analyze it together.

At present, XJM flotation machine has formed a series of products with various specifications. The tank (chamber) volumes are 4 m³, 6 m³, 8 m³, 10 m³, 12 m³, 14 m³, 16 m³, 20 m³, 24 m³, 28 m³, 36 mm³, 45 m³, 60 m³, etc.

The selection of an XJM flotation machine can be calculated through the following steps:

The number of flotation cells required for the XJM flotation machine is related to the flotation speed, particle size composition, and flotation concentration of the slurry. From the perspective of slurry flotation speed:

The flotation speed of easy-to-float slurry is fast, while the flotation speed of difficult-to-float slurry is slow; the particle size is fine The flotation speed of slurry is fast, and the flotation speed of slurry with coarse particle size is slow; when the amount of floating slurry is the same, the flotation speed of slurry with low concentration is fast, and the flotation speed of slurry with high concentration is slow.

For slurry with fast flotation speed, 3 flotation tanks can be used in one group;

For slurry with slow flotation speed, 4 or 5 flotation tanks can be used in one group. Group;

For 0.35mm~0.125mm particle size yield>50% and easy to float slurry, each group can choose 3 flotation tanks;

For the dominant particle size For slurries with particle size ≥0.35mm, the number of flotation cells in each group should be no less than 5.

When the flotability of the slurry is within the range of easy to difficult flotation, one-time flotation process can be used. Generally, the number of flotation cells in each group is no more than 4;

When the flotability of the slurry is difficult to flotation, it is recommended to use two flotation processes. Generally, 3 flotation cells are arranged for one flotation (coarse separation). When the particle size of the slurry is relatively coarse, 4 flotation cells can be arranged;

For secondary flotation (concentration), 2 flotation cells are generally arranged. For slurries with a roughing clean coal yield of more than 80%, high ash content and coarse particle size, 3 secondary flotation cells are suitable. flotation tank.

When the concentration of the flotation slurry is greater than 90g/L, Generally, the dry slurry processing capacity is used as the calculation basis for flotation machine selection; when the concentration of the flotation slurry is less than 90g/L, the calculation is generally based on the slurry processing capacity.

When selecting the XJM-S flotation machine, the equipment processing capacity should be taken as a large value for easily floating slurry, and vice versa; when the slurry dominates the particle size or the average particle size is coarse, the equipment processing capacity should be The processing capacity takes the smaller value; when the number of flotation tanks is less than 4, the equipment processing capacity takes the smaller value, and vice versa; in the two flotation processes, when the flotation machine is selected according to the required capacity of one flotation, The equipment processing capacity should be taken as a large value. If the particle size composition of the slurry is coarse, the intermediate value should be taken.

According to< a href="/solution" target="_self">Ore beneficiation process process calculation results determine the amount of flotation mud and the amount of flotation slurry, and use them as the basis for subsequent calculations; according to the XJM flotation machine Based on mineral processing experience, the imbalance coefficient generally takes a value of 1.25.

Generally, the fewer flotation machines are used, the less investment and construction of the mineral processing plant, and the lower the energy consumption and production cost per ton of slime. The number of flotation machines in the mineral processing plant is determined based on the flotation machine technology, the number, volume and quantity of individual flotation machine tanks, unit processing capacity and other parameters.

Have you remembered the XJM flotation machine model and selection tips introduced above? If you want to know more about flotation machine equipment types and flotation machine models, you can consult Xinhai Mining to help you recommend suitable flotation machine equipment and models.