15311826613

Click to add WeChatXJM-KS flotation machine is a type of flotation equipment. It is a new product that is a large-scale upgrade based on the XJM flotation machine. The flotation machine has a single tank volume of up to 60m³ and an aeration rate of up to 0.85 m³. / (m2·min), the aeration uniformity can reach 91%, and the installed power of the mixing mechanism can reach 110 kW. Let's take a look at this new type of flotation machine equipment.

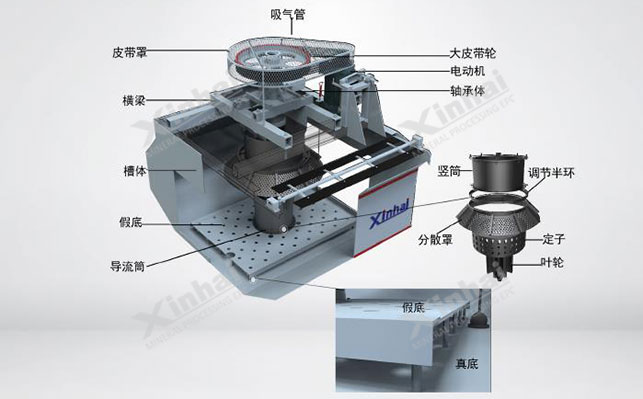

XJM-KS flotation machine mainly consists of mineralizer, driving device, stirring device It consists of mechanism, tank body, tailings box, false bottom flow stabilizing plate, bubble scraping mechanism, walking platform, etc. Its conventional configuration is 4 tanks.

The mineralizer consists of a pressure chamber, a mixing chamber, and an ejector , pharmaceutical atomizer, pressure gauge, etc., in which the pressure chamber and mixing chamber are connected by bolts. During the working process, the slurry is given to the pressure chamber of the mineralizer at a pressure of 0.08-0.15 MPa, and is ejected from the evenly distributed mineralization nozzles to form a jet to produce a "Venturi tube" effect, forming a certain degree of vacuum near the nozzle, which will The agent and air are inhaled from the suction tube and atomized in the suction tube, and then enter the throat together with the high-speed slurry; in the throat, the air, atomized agent and slurry transfer energy and mix through the mutual collision of the slurry flow. , a large number of turbulent vortices are generated during the mixing process. The strong eddy currents fully mix the air, atomized agent and slurry, thereby achieving pre-mineralization of clean coal particles. Afterwards, the pre-mineralized slurry directly enters the flotation machine for separation through the feed pipe. .

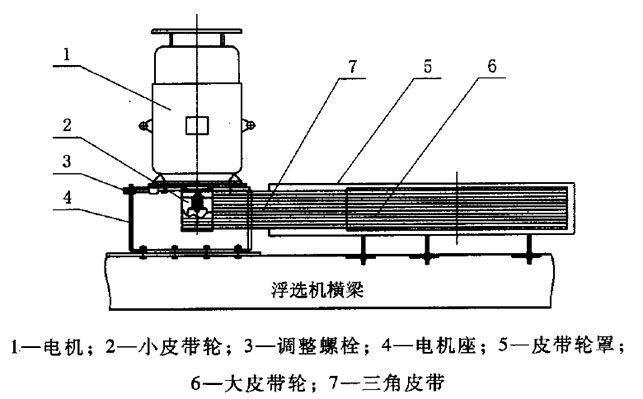

The flotation machine driving device mainly consists of motor, small pulley, adjusting bolt, motor It consists of seat, pulley cover, large pulley, triangle belt, etc. Taking into account the convenience of use, transportation, on-site installation and maintenance, the motor installation form is V1, and the motor base adopts a structure with the function of adjusting the belt tightness.

The XJM-KS flotation machine tank is round and made of Q235 steel plate. , using a built-in concentrate chute. The tank body is mainly composed of a simplified body, a small chute, a large chute, an ore discharge port, a reducer base plate, a concentrate discharge port, etc. This flotation machine is equipped with two additional chutes in the middle of the tank, which are distributed in a "one" shape, eliminating the chutes on both sides of the square flotation machine. Bubble scraping mechanisms are added on both sides of the chutes to share the middle chute and are installed on the tank barrel. A concentrate outlet flange is added to the wall, and only pipes are needed to connect the concentrate outlet and the concentrate pool on site.

The mixing mechanism consists of a pulley, a mixing bearing seat, and an air suction It consists of tube, casing frame, shaft, upper adjusting ring, bell housing, impeller, stator, stator cover, special nut, etc. The core components of the mixing mechanism are the impeller and stator group. The XJM-KS flotation machine adopts a split impeller-stator structure, which can bring great convenience to the production, transportation, installation and maintenance of the flotation machine.

The impeller of the flotation machine has an umbrella-shaped structure, divided into upper and lower layers of blades, and is installed in combination with a special nut with a diversion function to separate the impeller cavity. The body is divided into a suction chamber and a slurry suction chamber; the stator cover also has an umbrella-shaped structure. There are 20 slurry circulation holes on the umbrella-shaped surface. The axial gap between the impeller and the stator cover is 10±2 mm, which can be increased or decreased by The gasket between the bearing seat and the casing frame body is used to adjust the gap; there are 20 guide vanes evenly distributed at an angle of 60° to the radial direction around the stator, which serve to uniformly guide and stabilize the flow. The gap between the impeller and the stator is Radial clearance is also 10±2 mm.

In addition, the adjusting ring on the impeller is composed of two half rings, which is easy to install and replace. Its function is to adjust the circulation and inflation volume of the upper cavity of the impeller; the bell-shaped bell is in the form of a "bell mouth" shape, its function is to introduce air into the negative pressure area of the upper cavity of the impeller; the suction pipe is installed on the casing frame to suck air, and the wind blade is used to adjust the suction volume; the dosing pipe is installed on the casing It is installed on the tube frame body and distributed to the left and right of the suction pipe for point dosing.

The foam scraping mechanism is used to scrape the concentrate foam and is installed symmetrically on both sides of the built-in chute in the upper part of the tank body. The bubble scraping mechanism consists of a reducer, coupling, scraper, cross clamp, bubble scraping shaft, bearing seat, etc. The scraper is driven by a reducer and connected to the shaft by a clamping plate. The two sets of scraping mechanisms turn in opposite directions and scrape the clean coal foam into the built-in chute at the same time. The XJM-KS type flotation machine does not have an inter-shaft coupling on the scraping shaft. It has a compact structure and reliable operation. It does not have the problem of poor concentricity of the traditional flotation machine scraping shaft.

The structure of the false bottom flow stabilizing plate is as follows: A false bottom steel plate is installed at a certain height above the bottom of the tank, and there is a certain distance around the false bottom steel plate from the tank wall. There are 20 guide plates with a certain curvature welded on the false bottom, corresponding to the 20 guide blades of the stator, which play a role in extending the guide distance; a wear-resistant plate is welded on the guide plate corresponding to the discharge height of the impeller. ; In order to prevent the welding point at the root of the guide plate from being washed away for a long time and losing its diversion function, 3 closed-loop reinforcing ribs are added.

In addition, there is also a tapered suction pipe, which is arranged in the center of the false bottom steel plate and matches the size of the suction port under the impeller to suck in the false bottom. The slurry below can weaken the "whirlpool" effect formed by the slurry in the center of the true bottom.

The above is an introduction to the XJM-KS flotation machine, and also introduces its structural components and component characteristics. In actual processing plants, there are many types of flotation machines to choose from. Which one to choose? Which type and model should be determined according to the actual processing capacity and processing needs of the mineral processing plant. It is recommended to conduct a mineral processing test first, and customize the appropriate flotation machine type and model based on the test results, which is more reasonable.