15311826613

Click to add WeChatCopper and molybdenum ores are one of the important raw materials for my country's economic development. During mineral processing operations, some copper and molybdenum ores will coexist, so copper and molybdenum need to be separated. At present, the commonly used copper and molybdenum separation methods are mostly priority flotation processes, and the equipment used is mainly flotation machine and flotation column.

In traditional copper and molybdenum flotation operations, certain factors will affect the recovery rate of molybdenum ore beneficiation, which restricts the production of molybdenum ore. output rate. The effective use of flotation columns in copper-molybdenum flotation operations can effectively increase the recovery rate of molybdenum, which not only further simplifies the treatment process, but also increases the output rate of molybdenum and ensures the economic benefits of the enterprise.

Flotation is often an important part of modern flotation equipment. It can adapt to the complexity of flotation and has high performance. The level of automation has high application value. Its main advantages are as follows:

1. The flotation column can create a static separation environment suitable for the dynamic collision and combination of bubbles and particles for copper and molybdenum flotation, with low operating costs and high key recovery rate. High effect, in line with the basic needs of mining enterprises.

2. The flotation column can effectively improve the efficiency of flotation, and can effectively reduce the number of operations and the amount of circulating ore.

3. It has a wide range of applications and has a good effect of inhibiting hydrophilic particles, which can effectively increase the flotation concentration and maximize the enrichment ratio.

4. The use of flotation column technology can effectively reduce the use of chemicals, reduce energy consumption, and is low-cost.

5. The flotation column technology is simple to develop and prepare, has low construction cost and has high application value.

The principle of copper and molybdenum ore flotation column equipment can be divided into two parts. One is the technical principle, and the other is the working principle that we are familiar with. .

Principle of copper and molybdenum ore flotation column technology:The main mineral (copper-molybdenum ore) is pretreated, the surface of the mineral is treated, and the surface is treated reasonably The differences in water properties are analyzed and utilized, and the three-phase flow of solid, liquid, and gas is applied to copper and molybdenum minerals, thereby completing the separation of copper and molybdenum minerals and completing the flotation process.

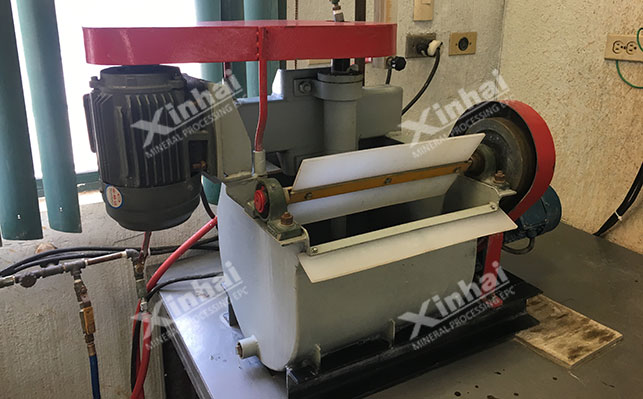

The working principle of the copper and molybdenum ore flotation column:When the flotation column is operating, the minerals need to be pretreated reasonably to make the minerals into slurry. The slurry is slurried through the distributor It is evenly sent to the flotation column. After entering, it moves slowly according to the cross section in the column, allowing the internal bubbles to collide with the slurry particles and combining with the static separation environment. The main thing is an air compressor combined with a microporous foamer to convert the high-pressure gas. Rat bubbles are evenly distributed on the surface of the mineral, making it mineralized bubbles. These mineralized bubbles will show an upward trend in the three-phase flow, become a foam layer on top of the flotation column, and flow into the concentrate tank. The remaining part will be discharged as tailings, thereby effectively completing the flotation of copper and molybdenum. select.

Flotation column can effectively apply the theory of three-phase flow dynamics and scientifically conduct spray gun foaming device Application, and then effectively convert high-pressure gas into a large number of bubbles; at the same time, it also completed the innovation of process technology, optimized the feeding method, and improved the mineralization effect.

In mineral processing operations, when selecting a flotation column, the working principle and influencing factors of the flotation column should be analyzed in detail. At the same time, the selected minerals must be Ore beneficiation test, and the appropriate flotation process and suitable flotation column model can be customized based on the actual situation. Can increase the output rate of copper-molybdenum minerals.