15311826613

Click to add WeChatNickel sulfide ore is one of the important sources of nickel resources, mainly composed of nickel-containing sulfides such as pentlandite ((Ni,Fe)9S8) and pyrite (Ni3S2). Since these minerals usually coexist with other metal sulfides (such as copper, cobalt, platinum group metals, etc.), and are often accompanied by a large amount of gangue minerals, appropriate beneficiation processes are needed to improve the grade and recovery rate of nickel. At present, the common nickel sulfide beneficiation processes mainly include flotation, magnetic separation, gravity separation, oxidative roasting-leaching, bioleaching and other methods. Let's learn about it together!

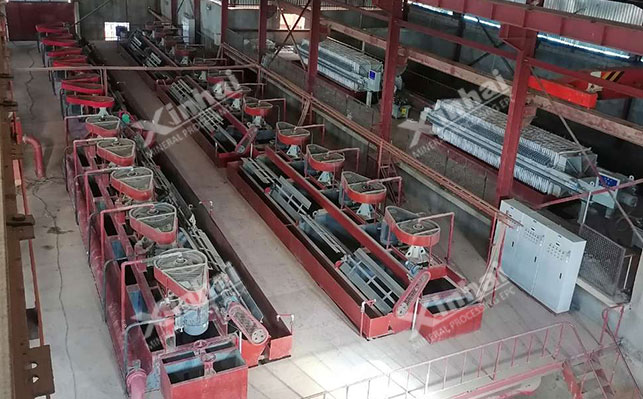

Flotation is a mineral processing method that makes the surface of the target mineral hydrophobic and adheres to bubbles based on the differences in the physical and chemical properties of the mineral surface, thereby achieving mineral separation. In the flotation of nickel sulfide ore, commonly used flotation agents include collectors, frothers and regulators. Collectors are generally xanthates and black drugs, which can selectively adsorb on the surface of nickel sulfide minerals to make them hydrophobic; frothers such as pine oil can produce stable bubbles to carry the target minerals to float; regulators are used to adjust the pH value and ion concentration of the pulp to improve the flotation effect.

This method can process various types of nickel sulfide ores, including low-grade, complex and difficult-to-select ores. It can effectively separate nickel sulfide minerals from gangue minerals and improve the nickel recovery rate and concentrate grade.

Magnetic separation is a mineral separation method that uses the magnetic difference of minerals for separation. Nickel sulfide minerals generally have weak magnetism, while gangue minerals are mostly non-magnetic or weakly magnetic. By using magnetic separation equipment, such as permanent magnetic drum magnetic separators, high gradient magnetic separators, etc., under the action of the magnetic field, the magnetic minerals are adsorbed on the drum or medium of the magnetic separator, and the non-magnetic minerals flow out with the slurry, thereby achieving the separation of minerals.

Compared with flotation, the process of magnetic separation is simpler, with less equipment investment, and does not require the use of a large amount of flotation reagents, which has less pollution to the environment. However, for nickel sulfide minerals with weak magnetism, the magnetic separation effect may not be ideal, and it needs to be used in combination with other mineral processing methods.

Gravity separation is a mineral processing method based on the density difference of minerals. Nickel sulfide minerals and gangue minerals usually have a certain difference in density. Gravity, centrifugal force and other effects are used to make minerals of different densities move in the medium, thereby achieving separation. Common gravity separation equipment includes jigging machine, shaking table, spiral chute, etc.

This beneficiation method has low overall cost, simple operation and maintenance, and no environmental pollution during the beneficiation process, but the separation efficiency of gravity separation is relatively low. It is generally used as an auxiliary beneficiation method in conjunction with flotation or magnetic separation.

First, the nickel sulfide ore is oxidized and roasted at a certain temperature to convert the sulfide minerals into oxides. In this process, the main reaction is the reaction of sulfide with oxygen to generate corresponding metal oxides and sulfur dioxide. Oxidative roasting can release nickel from the complex structure of sulfide, while removing most of the sulfur, creating favorable conditions for the subsequent leaching process.

Leaching is to mix the ore after oxidative roasting with a leaching agent and leach it under certain temperature and stirring conditions. Commonly used leaching agents include acids (such as sulfuric acid, hydrochloric acid, etc.) and ammonia.

The bioleaching process of nickel sulfide ore is a green and environmentally friendly technology that uses the metabolism of microorganisms to extract nickel from nickel sulfide ore. The growth and metabolism of microorganisms require a certain amount of time, and their oxidation and decomposition of nickel sulfide ore is a gradual process. Compared with traditional pyrometallurgy and some chemical leaching methods, the reaction rate of bioleaching is lower.

The above is an introduction to the nickel sulfide beneficiation process. In actual beneficiation plants, since each method has its own unique advantages and limitations, it is necessary to comprehensively consider the specific properties of nickel sulfide minerals, the types of minerals contained, and production conditions to select a suitable method. Therefore, it is recommended to conduct a ore dressing test first, and design a suitable nickel sulfide ore beneficiation process through experimental analysis.