15311826613

Click to add WeChatThe veins of aplite-type feldspar deposits are small and not wide. Most of them are produced in corresponding plutonic rocks, and occasionally appear in fissures in surrounding rocks near rock bodies. Let’s learn about the mineral processing process of aplite-type feldspar ore with the editor.

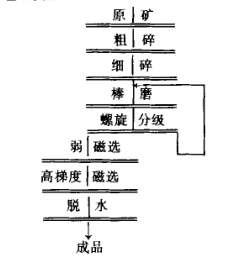

Generally, aplite-type feldspar ores contain mica and sometimes iron. During the mineral processing process, iron and mica need to be removed, so crushing-grinding-screening-magnetic separation is often used. Process flow.

This type of feldspar ore In the crushing stage, in order to dissociate the minerals as much as possible, two stages of crushing processes are often used: coarse crushing and fine crushing. The process is as follows: the raw ore is fed into a section of crusher (jaw crusher) by the feeder for coarse crushing, and the crushed products are conveyed by the belt The conveyor feeds it into the secondary crusher (cone crusher) for fine crushing, and the crushed products are transported to the storage silo for storage, ready for subsequent operations.

The grinding operation is to achieve monomer dissociation between minerals In this stage, a rod mill is often used for grinding, which forms a closed-circuit system with a screen for grinding. The process is as follows: the crushed products are fed from the feed bin to the belt conveyor, and then sent to Rod mill Grinds the ore in the rod mill. The grinding product is fed into the vibrating screen. The material under the screen enters the next step, and the material above the screen is returned to the rod mill for further grinding.

The magnetic separation stage mainly uses weak magnetic separation method. The process is that the products under the sieve pass through a midfield intensity magnetic separator to further remove mechanical iron, and a high gradient magnetic separator removes iron-containing minerals to obtain feldspar concentrate.

The above is an introduction to the processing process of aplite-type feldspar ore. In the actual mineral processing plant, according to the properties of the feldspar ore, Different mineral processing processes and the use of mineral processing equipment are also different. Therefore, it is recommended to design a suitable feldspar ore processing technology and a complete set of through mineral processing test analysis. Stone ore processing equipment can obtain the ideal feldspar concentrate.