The spiral chute has high separation efficiency, accurate ore separation, simple structure, small footprint and easy operation.

[Processing Capacity]:0.15~10t/h

[Ore feeding particle size]: 2.00~0.04mm

[Ore feeding concentration]: 25~55 %

[Scope of application]:The spiral chute can be used to sort iron, tin, tungsten, tantalum, niobium, and gold with a particle size of 0.3-0.02mm. Mine, coal mine, monazite, rutile, zircon and other metal and non-metal minerals with sufficient specific gravity difference.

15311826613

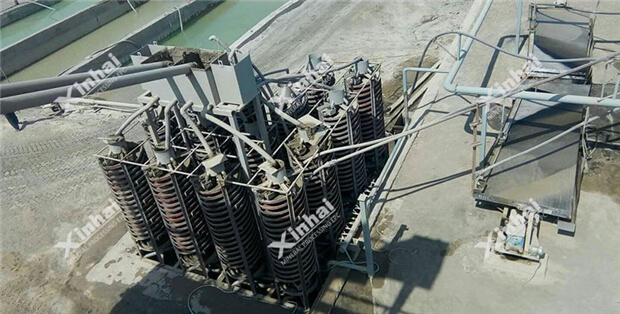

Click to add WeChatXinhai spiral chute equipment has low operating level requirements, a wide range of ore dressing particle size, small unit area, clear distribution of mineral zones, easy maintenance and low investment in management-level equipment.

Light in weight, rust-proof, wear-resistant, and corrosion-resistant;

Occupies little space, consumes less water, does not require power, and has a long service life;

In terms of the amount of ore fed, Strong adaptability to fluctuations in concentration, particle size, and grade;

The spiral chute is cheap, simple to install, easy to operate, small investment, and quick in profits;

The friction formed on the emery surface makes the mineral processing The effect is better than other plastic surfaces.

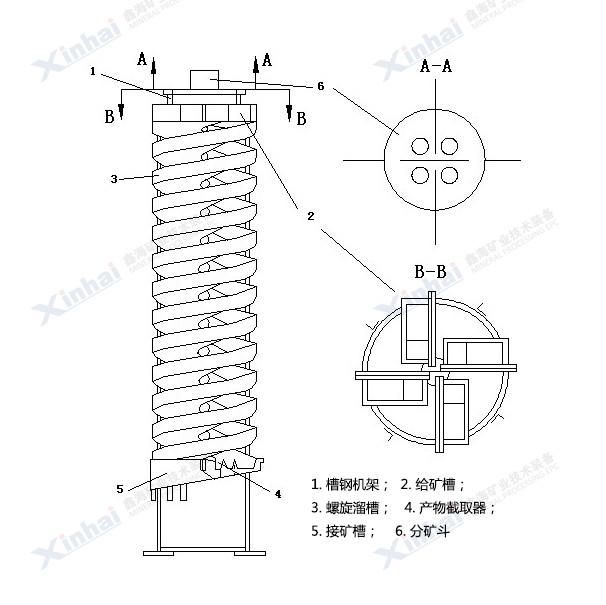

The spiral chute structure mainly consists of a spiral chute, a feeding trough, a receiving trough, a channel steel frame, a product interceptor, and an ore dividing hopper.

The slurry is evenly fed into the spiral chute. The tail end of the spiral chute is equipped with a valve block product interception groove, which divides the sorted products into three types according to grade along the radial direction. Use the position of the adjusting valve block to change the interception width of each product, and the product accumulation hopper will collect and export the intercepted multi-head ore flows separately. The cross-section of the spiral chute and the slope change of the curve are particularly suitable for sorting fine particles.

山东海滨某选矿厂矿石除少量颗粒较大外,主要分布在-0.15mm粒级,矿山占地面积较小,但处理量大。鑫海螺旋溜槽生产厂家根据客户厂房选址和处理量,为增加螺旋溜槽的使用期限,特意给螺旋溜槽内部添加了耐磨橡胶以增加机器的耐磨性,同时又可耐酸、耐腐蚀。客户实际使用机械过程中矿物分层明显,机器使用寿命较普通溜槽延长半年。

| Model | BLL-2000 | BLL-1500 | BLL-1200 | BLL-900 | BLL-600 | BLL-400 | ||

|---|---|---|---|---|---|---|---|---|

| 螺旋外径(mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | ||

| 螺距(mm) | 1200 | 900, 675 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 | ||

| 距径比(螺距/直径) | 0.6 | 0.48, 0.36 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 | ||

| 横向倾角(° ) | 9° | 9° | 9° | 9° | 9° | 9° | ||

| 安装螺旋头数 | 3 | 4 | 4 | 4 | 2 | 2 | ||

| 给矿粒度(mm) | 2.00~0.04 | 0.8~0.037 | 0.3~0.03 | 0.3~0.03 | 0.2~0.02 | 0.2~0.02 | ||

| 给矿浓度(%) | 30~55 | 30 ~55 | 25 ~55 | 25 ~55 | 25 ~55 | 25 ~55 | ||

| 生产能力(t/h) | 7~10 | 6~8 | 4~6 | 2~3 | 0.8~1.2 | 0.15~0.2 | ||

外形尺寸 | 长(mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 | |

宽(mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 | ||

高(mm) | 5600 | 5300 | 5230 | 4000 | 2600 | 1500 | ||

| 重量(kg) | 900 | 850/800 | 700/650/600 | 450/400/350 | 120/100/80 | 50 | ||

建议通过选矿试验,根据试验分级结果,定制适合的螺旋溜槽设备。