15311826613

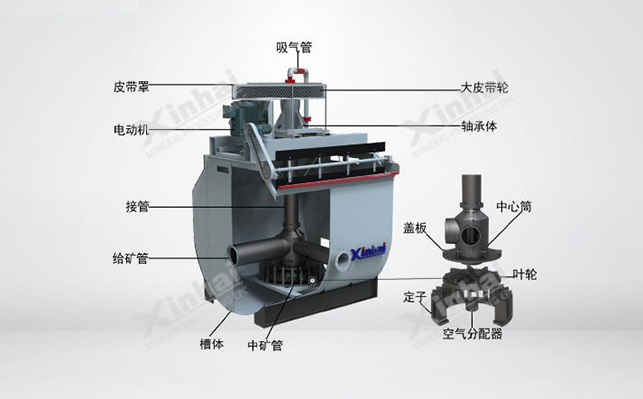

Click to add WeChatXCF flotation machine (XCF type) is a type of inflatable agitator flotation machine that can self-prime slurry. The flotation machine not only has a mechanical stirring device, but also uses a fan to force air into the flotation machine. The mechanical stirring device only plays the role of stirring the slurry and distributing air flow. The air is mainly pressed in by an external fan, and the aeration and stirring of the slurry are separated.

The xcf flotation machine produced by Xinhai has a simple structure, is easy to maintain, has low energy consumption and high energy saving efficiency. It can save about 30% of energy compared with conventional flotation machines; wearing parts such as impeller and stator are made of durable Made of grinding material, it has low wear, strong stirring ability, good slurry circulation and low chemical consumption.

In addition, the XCF flotation machine can be used with KYF type inflatable flotation The machine forms a combined unit. When designed and installed, the flotation circuit can be automatically formed at the same horizontal configuration interface without the need for foam pumping, which reduces pump investment and infrastructure investment.

The working principle of XCF Flotation Machine is that the motor drives the transmission device and the hollow shaft drives the impeller to rotate to ensure mechanical mixing. Then an external blowing device is used to introduce air, which enters the air distributor in the lower impeller cavity through the cross beam, air regulating valve, and hollow spindle, and then enters between the lower blades of the impeller through the peripheral pores of the air distributor. The slurry is rotated by the impeller and covered. The combined action of the plate and the central cylinder generates negative pressure in the upper blades of the impeller, which then enters the central cylinder, enters between the upper blades of the impeller, and is then discharged from the outer edge of the upper blades.

When the slurry in the XCF flotation machine tank enters the bottom of the tank from the surroundings, it is sucked into the lower blade of the impeller through the inner edge of the lower blade of the impeller. time, it is fully mixed with the charged air in the space between the lower blades of the impeller, and then is discharged from the outer edge of the lower blades. The discharged slurry and air mixture mixes with the medium ore and feed ore discharged from the outer edge of the upper blades of the impeller, and is stabilized by the stator. The mineralized bubbles rise to the surface to form a foam layer, and the remaining slurry will return to the lower blades of the impeller to continue circulation.

Xinhai’s It consists of pipe, medium ore pipe, suction pipe, impeller, stator, cover plate and air distributor.

The tank of this flotation machine adopts a special U-shaped cross-section structural design , can effectively improve the flotation effect. However, if the volume of the flotation tank is less than 3m3, in order to facilitate production and installation, a trapezoidal tank design can be used.

In addition, the XCF flotation machine can be combined with the KYF flotation machine to form a combined unit. At this time, in order to facilitate the connection of the tank body, the shape of the tank body can be consistent with the DC tank.

The XCF type flotation machine bearing body is divided into an inflatable stirring area and a slurry suction area. The aeration mixing zone is composed of the lower blades of the impeller and the air distributor; the slurry suction zone is composed of the upper blades of the impeller, cover plate, central cylinder and nozzle (connecting pipe).

The impeller of this flotation machine has an isolation disk, which can effectively separate the upper and lower blades. The upper blades of the impeller have no additional aeration interference, and the upper blades can form Large negative pressure is used to suck the slurry, while the blades under the impeller are responsible for circulating the slurry and dispersing the air.

The cover is mainly installed on the lower part of the center cylinder of the flotation machine. It forms a closed space with the intermediate isolation disk of the impeller. When the impeller rotates, a negative pressure is formed to realize the pulp suction function. At the same time, the cover can also play a role in isolating the inside of the tank in the slurry suction area, effectively preventing the filled air from being introduced into the slurry suction area.

The stator of the XCF flotation machine adopts a suspended radial short blade open stator design, which is installed obliquely above the impeller. The legs are fixed to the bottom of the trough. Its function is not only to redirect the slurry flow and shear the air, but also to ensure that the air filled into the slurry through the lower blade of the impeller is not blocked by the stator and can smoothly enter the main tank instead of entering the slurry suction area.

The air distributor is used to improve the inflation and dispersion of the flotation machine impeller. It is installed in the lower blade cavity of the impeller and can pre-distribute the air. Evenly distributed in most areas of the rotor blades, providing a large amount of slurry-air interface, improving the impeller's ability to disperse air.

The takeover (connecting pipe) is used to fix the central cylinder and cover plate There is a vent hole on the upper part of the pipe to eliminate the air generated by the bursting of the middle ore foam and the slurry backflow into the central cylinder.

The above is an introduction to the working principle and structural characteristics of the XCF flotation machine. I believe everyone has some understanding of this flotation machine. So how is this flotation machine specifically applied and what mines are it suitable for? What about minerals? Looking forward to our next sharing.