15311826613

Click to add WeChatThere are many refractory gold ore resources in my country, and the gold is wrapped in gangue minerals and harmful impurities in fine particles and microscopic forms, which is a characteristic of refractory ores. For this kind of refractory gold, flotation and cyanidation methods often cannot achieve a more ideal gold recovery rate. This article takes carbon-arsenic refractory gold ore as an example to introduce its fine-grained refractory gold ore flotation process method.

The metal ore in this mineral is mainly pyrite, followed by arsenopyrite, and also contains a small amount of limonite, sphalerite, chalcopyrite and tetrahedrite; trace minerals include galena, native gold, silver gold ore and native silver. Non-metallic minerals are mainly quartz, followed by carbonates and sericite.

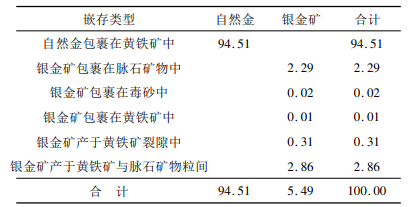

Among them, gold is mainly contained in pyrite, gangue ore and arsenopyrite, and the main gold-bearing minerals in metal ore are pseudopyrite and arsenopyrite. The particle size of pyrite is mainly coarse and fine, and that of arsenopyrite is mainly fine, both of which are in an unevenly embedded state.

Through microscopic identification, natural gold is completely wrapped in pyrite, and the embedded state is relatively simple. Silver-gold ore is mainly embedded between pyrite and gangue mineral particles, in contact with the edge of pyrite, and secondly, wrapped in gangue minerals, and a small amount is embedded in pyrite cracks.

Through research, it was found that the gold in this ore includes visible gold and invisible gold. From the analysis of the embedded particle size of visible gold minerals, the natural gold particle size is coarser, while the embedded particle size of silver-gold ore is generally less than 10 μm. The embedded particle size of silver-gold ore in pyrite and arsenopyrite is finer, generally less than 1 μm. Through electron probe analysis, invisible gold is mostly present in arsenopyrite, followed by pyrite and gangue minerals.

Through the beneficiation test analysis of the carbon-containing fine-grained gold ore, the process flow of grinding-pre-decarbonization-flotation gold extraction was finally designed.

To recover the target mineral (or carrier mineral), various minerals must be basically dissociated into monomers to achieve a better flotation effect. Finally, it was decided to adopt a two-stage closed-circuit grinding process, with a grinding fineness of -0.038 mm and a mass fraction of 80%, to improve the monomer dissociation degree of gold minerals and gold-bearing minerals.

Since the ore contains arsenic and carbon, and carbon seriously interferes with the recovery of gold, it was decided to carry out decarbonization first. The carbon obtained after decarbonization is organic carbon, and the carbon concentrate obtained after decarbonization can be sold to relevant smelters.

Pre-decarburization is to grind the mineral to -0.038 mm with a mass fraction of 75%, add water glass and No. 2 oil to disperse the ore mud, achieve decarburization, and then perform flotation roughing to obtain coarse gold concentrate.

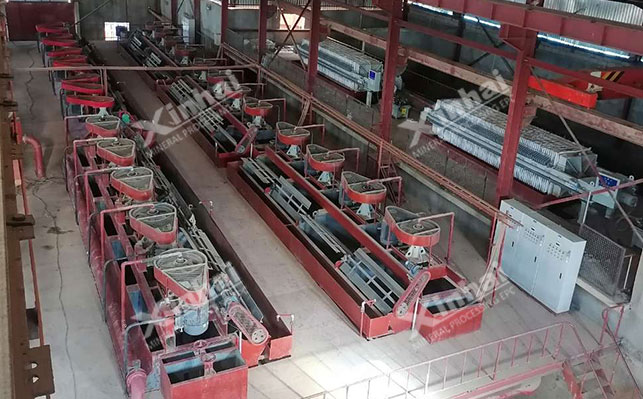

During the flotation process, butyl xanthate is used as the main flotation collector and butyl ammonium black medicine is used as the auxiliary flotation collector; NC (a composite reagent) is used as the adjusting agent to adjust the pH value of the ore pulp; copper sulfate is used as the activator (dosage 200g/t), and the amount of water glass is 500g/t. The process of secondary roughing, secondary concentrating, and tertiary scavenging is carried out to complete the flotation of gold ore.

The above is an introduction to the flotation process of a carbon-containing fine-grained gold ore. In the actual beneficiation process, how to select gold depends on the properties of the gold ore. Therefore, it is recommended to conduct a ore dressing test analysis first, and design a suitable gold ore beneficiation process plan through analysis. At the same time, a set of gold ore beneficiation equipment can also be customized according to the process.

Content excerpted from: Research on flotation process of a carbon-containing fine-grained gold ore