15311826613

Click to add WeChatMolybdenum is a refractory metal with high boiling point and high melting point, low linear expansion coefficient and high thermal conductivity, and high elastic modulus. These characteristics make molybdenum and its compounds widely used in electrical, steel, chemical, energy and other fields. The content of molybdenum in nature is very low. Among them, copper-molybdenum polymetallic ore is one of the main sources of enriched molybdenum. So how to effectively extract molybdenum from copper-molybdenum polymetallic ore? The following takes a certain sulfide copper-molybdenum ore as an example to introduce its molybdenum ore dressing process.

The main metal elements in the copper-molybdenum sulfide mineral are copper ore and molybdenum ore. Other metal elements also include pyrite, pyrrhotite, magnetite, galena, sphalerite, ilmenite, hematite, etc.; among the precious metal minerals, gold is mainly natural gold, followed by silver-gold ore, tellurium silver ore, argentite, etc. The main gangue minerals are albite, potassium feldspar, biotite, chlorite, epidote, common pyroxene, amphibole, calcite and quartz, followed by apatite, rutile, titanite and zircon, etc.

The metal elements with recoverable value in the mineral are mainly copper (grade 0.56%), molybdenum (grade 0.013%), and gold (grade 0.36g/t). Among them, copper is mainly chalcopyrite, followed by bornite, blue chalcocite, covellite and tetrahedrite; the main mineral element of molybdenum mineral is molybdenite; most of the gold exists in the form of monomers and exposed gold, and a small part is contained in sulfides such as chalcopyrite and pyrite. The proportion of gold wrapped in gangue minerals is not large. Overall, the mineral composition of this copper-molybdenum polymetallic ore is relatively complex, and the separation is difficult.

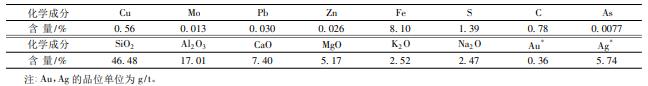

Through the mineral phase test analysis of the ore sample, the phase analysis results of the main minerals such as copper, molybdenum and gold are shown in the following table:

The phase analysis results of copper and molybdenum show that the oxidation degree of the ore is very low, and the copper and molybdenum elements mainly exist in the form of sulfides; gold mainly exists in the form of monomers and exposed gold, which is conducive to the flotation enrichment and recovery of gold. Finally, according to the test analysis, the grinding classification-isofloatable flotation process was designed for it.

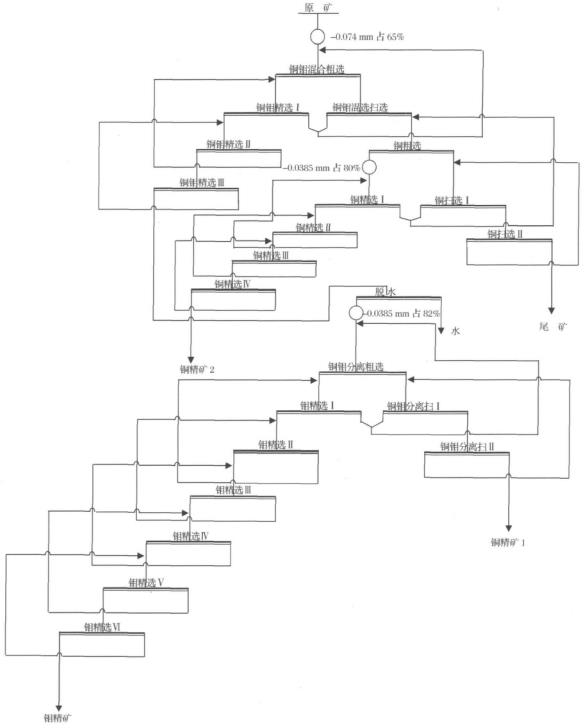

Through the test analysis of the ore, it was determined that the recoverable metal minerals in the ore are mainly copper, gold and molybdenum. According to the properties of the ore, the embedded particle size of copper is finer, and the particle size of gold is also finer. Fine grinding can increase the monomer dissociation degree between minerals, especially between the target mineral and the gangue. Considering the grinding cost and the tailings will be used as mine backfill, the roughing grinding fineness is -0. 074mm, accounting for 65%. In order to improve the grade of the concentrate, the coarse concentrate is re-grinded and selected.

The flotation stage adopts the isofloatable-copper-molybdenum separation process. In the copper-molybdenum separation process of copper-suppressing and molybdenum-floating mixed concentrate obtained by isofloatable, copper minerals are relatively easy to be suppressed, which can improve the pulp conditions for copper and molybdenum separation, reduce the amount of inhibitors, the viscosity of the pulp during copper-molybdenum separation, and the production cost of copper and molybdenum separation.

The above is an introduction to the process case of extracting molybdenum from a copper-molybdenum polymetallic ore. In an actual ore dressing plant, how to select (extract) molybdenum depends on the properties of the molybdenum ore. If it contains polymetallic ores, its ore dressing is more difficult. Therefore, it is recommended to conduct ore dressing test analysis first, and then design a suitable molybdenum ore dressing process plan. At the same time, a set of molybdenum ore dressing equipment can be configured according to the process flow to improve the recovery rate of molybdenum.