The double-impeller leaching mixing tank mixes evenly and has a long service life. It adopts multi-point air supply to ensure uniform aeration.

【Processing Capacity】:6-395m³

【Effective volume】:7.07~480m3(Can be customized according to needs)

[Scope of application]:Suitable for gold leaching, adsorption and other mixing operations where the specific gravity is small, the viscosity is low, the settling speed is slow, the ore particle size is -200 mesh accounting for more than 90%, and the slurry concentration is less than 45%.

15311826613

Click to add WeChatThe impellers of the leaching mixing tank produced by Xinhai Mining are lined with wear-resistant rubber, which extends the life of the impeller and improves the utilization rate of the mixing tank. In addition, its compact structure design reduces the difficulty and speed of maintenance.

The ore flow moves smoothly, the slurry is mixed evenly, and the power consumption is low;

The air enters the tank through the transmission hollow shaft and is stirred by the blades, and the air is evenly dispersed;

The hollow shaft is ventilated to the bottom , the air enters the tank through it, disperses evenly, and has small bubbles;

The impeller of the stirring tank has a large diameter, low speed, and low stirring power consumption, which can reduce the wear of carbon;

Stirring intensity Moderate, the slurry concentration and fineness distribution in the tank are consistent, which can improve the cyanide leaching rate and carbon adsorption rate;

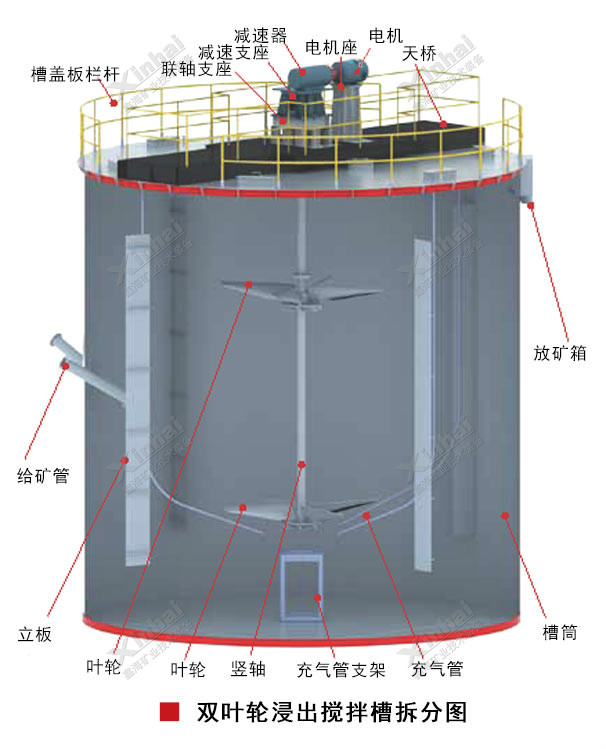

The main structural components of the mixing tank are: cylinder, ore discharge box , feeding pipe, impeller, vertical shaft, inflatable pipe, reducer, motor, slot cover, slot cover railing, coupling support and other parts.

The slurry leached out of the mixing tank flows from top to bottom in the center under the drag and stirring action of the double impeller, and diffuses through the peripheral damping plates. Air is fed into the lower end of the shaft, mixed with the slurry and circulates upward to form Homogenous suspension mixture.

A gold mining plant in Shaanxi was built in 2010 The mineral processing plant with a daily processing capacity of 200t/d adopts the direct cyanide-zinc powder replacement process. Because the originally installed double-impeller mixing tank mixing paddle blades were slightly smaller and the rotation speed was lower, the slurry was unevenly stirred, which was not conducive to the leaching of gold. Later, we contacted Xinhai Mining to undertake the cyanide process. Xinhai modified equipment uses slightly larger stirring blades and is equipped with an anti-backdraft device at the bottom of the hollow shaft. Due to the good ventilation in the center and uniform mixing of sodium cyanide, a major breakthrough was achieved in increasing the gold leaching rate from 94.28% to 97.14%.

| Model | Tank specifications (diameter | Impeller diameter (mm) | Motor Model | Motor power (kW) | Reducer Model | Tank weight (kg) | Total weight (kg) | ||

|---|---|---|---|---|---|---|---|---|---|

| SJ2.0X2.5 | 2000X2500 | 7.07 | 52 | 909 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 1609 | 2144 |

| SJ2.5X2.5 | 2500X2500 | 10.8 | 43 | 935 | Y112M-4 | 4 | XLD4-5-35 | 2159 | 2729 |

| SJ2.5X3.15 | 2500X3150 | 13.92 | 52 | 935 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 2398 | 3095 |

| SJ3.0X3.0 | 3000 X3000 | 19 | 43 | 1130 | Y112M-4 | 4 | XLD4-5-35 | 3480 | 4583 |

| SJ3X3.15 | 3000X3150 | 20 | 3480 | 4160.6 | |||||

| SJ3X3.5 | 3000X3500 | 22.97 | 3211 | 4334.6 | |||||

| SJ3.15X3.55 | 3150X3550 | 25.73 | 1260 | 3433.5 | 4322.8 | ||||

| SJ3.5X3.5 | 3500X3500 | 31.3 | 52 | 1310 | Y132S-4 | 5.5 | XLD5.5-5-29 | 3480 | 5025 |

| SJ3.5X4 | 3500X4000 | 35.6 | 4230 | 5429 | |||||

| SJ3.55X4.0 | 3550X4000 | 36.8 | 43 | Y112M-4 | 4 | XLD4-5-35 | 4260 | 5025 | |

| SJ3.7X4.2 | 3700X4200 | 42 | 42 | XLD4-5-43 | 5266 | 6153 | |||

| SJ4.0X4.5 | 4000 X4500 | 52.78 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 6397 | 7569 |

| SJ4.0X6 | 4000 X6000 | 71 | 33 | 1750 | Y160M-4 | 11 | GRF137-Y11- 4P-44.65-M4 | 7681 | 9200 |

| SJ4.5X5.0 | 4500 X5000 | 74.75 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 8614 | 10864 |

| SJ5.0X5.6 | 5000X5600 | 104.5 | 31 | 2046 | Y160M-4 | 11 | XLD11-8-47 | 8740 | 14291 |

| SJ5.5X6.0 | 5500 X6000 | 135.42 | 2100 | 12467 | 18745 | ||||

| SJ6.5X7.0 | 6500 X7000 | 215 | 21 | 2400 | Y180L-4 | 22 | GRF147-Y22- 4P-70.87 | 17890 | 25978 |

| SJ7.0X7.5 | 7000 X7500 | 269 | 2400 | Y200L2-6 | 22 | XLD22-10-47 | 20505 | 29030 | |

| SJ7.5X8.0 | 7500 X8000 | 331 | 23 | 2900 | Y200L2-6 | 22 | BLD7-43-22L | 22552 | 32796 |

| SJ8.0X8.5 | 8000X8500 | 402 | 18.5 | 3200 | Y250M-8 | 30 | TPS315-3F | 30559.5 | 42467.3 |

| SJ8.5X9.0 | 8500X9000 | 480 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 34130 | 46623 |