15311826613

Click to add WeChatManganese is widely distributed in nature and is contained in almost all kinds of ores and silicate rocks. According to the mineralization conditions of manganese ore, it can be divided into two categories: manganese oxide ore and manganese carbonate ore. In terms of mineral processing methods, according to the different properties of the ore, the selected mineral processing methods are also different. At present, the main applicable manganese ore mineral processing methods are: washing MineScreening method, Gravity separation method, Strong magnetic separation method, Flotation method, Combined Ore dressing methodandleaching method, fire enrichment method, etc. Let’s take a look at these manganese ore beneficiation methods.

The manganese ore washing method mainly uses hydraulic washing or additional mechanical scrubbing to separate the ore and mud. Usually, the ore washing operation is accompanied by the screening operation, such as directly flushing water on the vibrating screen or sending the ore (clean ore) obtained by the ore washing machine to the vibrating screen for screening. Screening can be used as a stand-alone operation to separate products of different particle sizes and grades for different uses. Commonly used equipment includes ore washing screens, cylinder washers and trough washers.

At present, the gravity separation method is only suitable for the separation of manganese ore with simple structure and coarse embedded particle size. , especially dense manganese oxide ores. The process flow for processing manganese oxide ore is generally to crush the ore to 6-0mm or 10-0mm, then classify the coarse grade particles and send them to jig sorting , and fine-grade particles are sent to the shaker for sorting. The methods that can be used are Heavy media beneficiation, Jig beneficiation and Shaking table beneficiation.

Manganese minerals are weakly magnetic minerals (specific magnetization coefficient X=10×10-6~600× 10-6cm3/g), it can be effectively recovered in a strong magnetic field magnetic separator with magnetic field strength Ho=800-1600kA/m (10000-20000oe), which can generally be increased by4% -10% manganese grade.

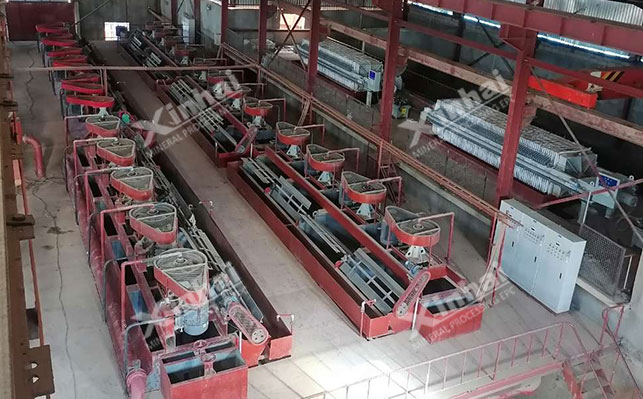

Because the magnetic separation method has the characteristics of simple operation, easy control and strong adaptability, it is widely used in the separation of various manganese ores. In recent years, it has occupied an important position in manganese ore beneficiation. Various new Coarse, medium and fine-grained strong magnetic machines have also been successfully developed.

Put the qualified particle size into The manganese ore is fed into the magnetic separator for weak magnetic separation to obtain strong magnetic manganese concentrate and weak magnetic separation tailings. The tailings are fed into the magnetic separator for strong magnetic separation to obtain strong magnetic separation tailings and concentrate. The concentrate is fed into Enter the gravity separation equipment for separation to obtain gravity separation manganese concentrate and tailings.

The strong magnetic separation and flotation method has good adaptability, and the strong magnetic separator not only effectively removes ore slime , and improve the selection grade of flotation. Comprehensive manganese concentrate products can be directly obtained by using strong magnetic flotation desulfurization; using sodium petroleum sulfonate instead of oxidized paraffin soap as the collector, the slurry can be separated at neutral and normal temperatures, saving chemical and energy consumption .

Usually, manganese ore leaching methods include direct leaching, roasting leaching and biological leaching. Among them, direct leaching methods include dithionate method, sulfur dioxide method, ferrous sulfate method, etc.

Take the sulfur dioxide manganese leaching method as an example. The manganese ore is slurried, sulfur dioxide gas is introduced, and the manganese oxide in the ore is converted into MnSO4 and MnS2 sub>O6. Add lime milk to the filtrate to produce manganese hydroxide precipitation, and obtain solid manganese hydroxide after filtration. This method is suitable for processing low-grade, fine-grained manganese oxide ores.

The fire enrichment method of manganese ore is a method for treating high-phosphorus, high-iron and difficult-to-select manganese-poor ores. It is generally called manganese-rich slag. This method mainly uses the difference in reduction temperature of manganese, phosphorus and iron to selectively separate manganese, phosphorus and iron by controlling their temperature in a blast furnace or electric furnace. The fire enrichment method has simple process and stable production, and can effectively separate iron and phosphorus in the ore to obtain manganese-rich, low-iron and low-phosphorus manganese-rich slag. This manganese-rich slag generally contains Mn35-45%, Mn/ Fe12-38, P/Mn<0.002, is a manganese alloy raw material. It is also an artificial rich ore that is difficult for natural manganese-rich ores to achieve the above three indicators at the same time.

The above are several common processing methods for manganese ore beneficiation. No matter which mineral processing method is determined by the properties of the ore, blind imitation is likely to cause the loss of manganese resources and reduce the return on investment. , Therefore, the editor recommends that the manganese ore beneficiation test be conducted first, and through test analysis, a reasonable beneficiation process, construction plan of the ore dressing plant, and equipment used in the ore dressing plant can be designed. If you have any needs, please feel free to consult Xinhai Mining Equipment!