15311826613

Click to add WeChatManganese is a type of metallic mineral. Currently, more than 150 manganese minerals have been discovered. However, there are not many manganese minerals with mining value. The main types of deposits can be divided into: Oxidation Manganese ore, carbonate manganese ore, iron-manganese ore, manganese-containing iron ore and polymetallic composite manganese oreThe mineral processing methods used are also different depending on the properties of the ore. The following editor will focus on this 5 introduces Manganese ore beneficiation process for each type of mineral deposit.

Manganese oxide ore accounts for the majority of the available manganese ores. A large amount of sludge is often produced in surface manganese oxide ores, but the sludge usually contains a large amount of manganese minerals, so the treatment of manganese sludge is also a very important aspect. On the basis of this classification, according to the different levels of manganese content and mineral dissipation particle size, it can be divided into massive disseminated manganese-rich ores, small and granular disseminated manganese-poor ores, and fine granular disseminated manganese-poor ores.

The manganese content in this type of manganese ore is relatively high, and the upper limit of selected particle size is between 40-75mm, simple manganese ore beneficiation methods can be used for separation, and higher-grade manganese concentrate can be obtained through screening or gravity separation. Therefore, commonly used manganese ore beneficiation methods include Heavy medium beneficiation method, Jig beneficiation method, Shaking table beneficiation method, etc.

The manganese content in this type of manganese ore is low, usuallyLess than 30%, and the manganese ore particle size is small and the mud content is large, so the treatment method is more complicated. Since manganese ore itself has weak magnetism, currently this type of manganese ore is often recycled using the gravity-magnetic-flotation combined process, that is, first washing >Select part of the sludge containing manganese minerals, and then use the combined process of jigging gravity separation-strong magnetic separation-flotation to recover manganese minerals.

The manganese content in this type of manganese ore is generally< strong>Less than 15%, and the particle size is very small and evenly distributed. It is difficult to use a single mechanical beneficiation method for recycling, usually Chemical leachingor mechanical beneficiation and chemical leaching combined process are treated.

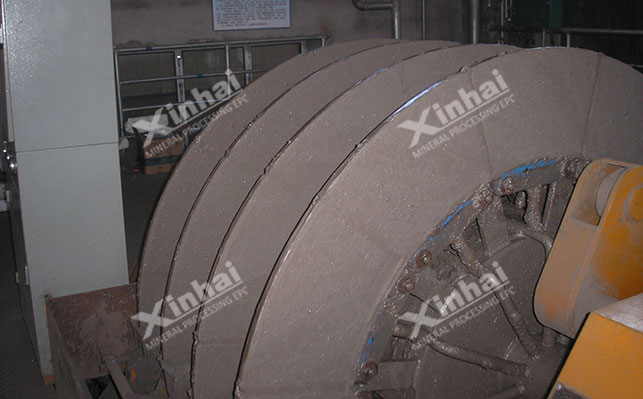

The manganese mineral in carbonate manganese ore mainly exists in the form of manganese carbonate, and the particle size is fine. Flotation is the main beneficiation method for this type of manganese ore, but there are problems such as large metal loss and high chemical consumption. Therefore, it is necessary to cooperate with Strong Magnetic Separation or Gravity Separation Method during production.

Iron-manganese ore generally uses manganese as the main recovered metal, the total content of manganese and iron is greater than 30%. Compared with manganese oxide ore, iron-manganese ore is more difficult to select, and the difficulty in selecting it lies in the separation of iron minerals and manganese minerals. In production, the washing-jigging gravity separation-roasting magnetic separation method can be used to recover iron ore concentrate and manganese concentrate, and a manganese concentrate containing 5.4% iron and 46.3% manganese can be obtained. The recovery rate can reach 75.5%.

This type of ore contains low manganese content, only 5%-10%, and also has fine particle size, iron-manganese minerals embedded in it. Due to the characteristics of close symbiosis, it is difficult to recover using mechanical beneficiation. Chemical leaching is a commonly used beneficiation method for this type of manganese ore, and the recovery index obtained is significantly better than the traditional mechanical separation method.

In addition to manganese minerals, there are also certain amounts of iron, lead, zinc, magnesium, aluminum, copper, Metal minerals such as silver mostly exist in the form of oxide ores. Among them, manganese minerals are closely combined with silver, iron and other minerals and are difficult to separate. For this type of ore, mineral separation methods such as strong magnetic separation, gravity separation, and flotation can be used. First, the manganese ore slime is separated out by washing and screening, and then other recyclable minerals are sorted.

The above is an introduction to the manganese ore beneficiation processes for five different deposit types. As for which process to choose, it is ultimately necessary to understand the type of manganese ore and then decide based on the mineral processing test analysis. Therefore, it is recommended that mine owners seek consultation from manufacturers with overall qualifications for beneficiation plants, select a reasonable manganese ore beneficiation process through scientific beneficiation test reports, and tailor-made Manganese ore beneficiation equipment cannot be chosen blindly.