Xinhai rod mill has large output, uniform particle size and no grinding. It can be divided into three types: overflow type, end peripheral discharge type and center peripheral discharge type. In addition, dry rod mills are also available. selection to meet the various needs of customers.

[Processing Capacity]: 0.62~250t/h

[Feeding particle size]:≤25mm

[Discharge particle size]:≤0.2mm

p>[Application Environment]:It can be used for coarse grinding operations in the grinding process and fine crushing operations in the crushing process.

15311826613

Click to add WeChatThe tapered end cover of the rod mill has a small curvature, which allows the steel rods to move regularly in the mill;

The ore discharge hollow shaft has a larger diameter, which is convenient for maintenance and can reduce the ore slurry liquid. Surface, rapid discharge of ore;

Normally, the feeding particle size range of the rod mill is 20~30mm, and the product particle size can generally reach 0~3mm;

The rod mill grinds the ore to The whole length of the steel rod is used to grind the materials, the force is uniform, the product particle size is uniform, and there is less over-grinding.

The particle size of the material grinded by the rod mill in open circuit is almost the same as that of the ball mill in closed circuit. The rod mill can save more than 40% of power during grinding.

The inlet and outlet device of the rod mill has good controllability, and can match the appropriate grinding body according to the user's actual grinding materials, and grind the materials in a line contact manner to make the discharge particle size of the materials more uniform. , and the yield is also higher.

The sand rod mill is equipped with a fineness control device inside, which can adjust the discharging particle size through simple operations. In addition, a screening device can also be added to the discharging material. Double checks ensure that Grinding also ensures the accuracy of qualified products.

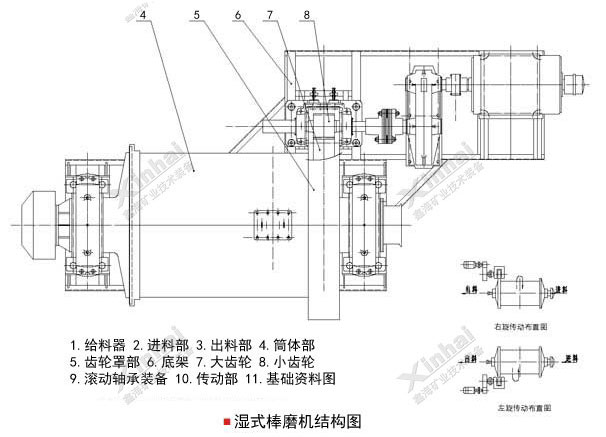

The structural components of the rod mill mainly include the cylinder, end cover, transmission part, main bearing, lining plate (cylinder, end cover), ore feeder, ore feeding port, ore discharge port, etc.

The working principle of the rod mill is that the motor drives the cylinder to rotate through the reducer and the surrounding large gear reduction transmission, or the low-speed synchronous motor directly passes through the surrounding large gear reduction transmission. The cylinder is equipped with appropriate grinding media - steel rods. The grinding medium is lifted to a certain height under the action of centrifugal force and friction, and then falls down in a falling or leaking state. The ground material continuously enters the inside of the cylinder from the ore feeding port, is crushed by the moving grinding medium, and is discharged out of the machine through overflow and continuous ore feeding force for the next step of operation.

| Model | 筒体直径 (mm) | 筒体长度 (mm) | 电机Model | Motor Power (kW) | 电机转 数 (r/min) | 长 (mm) | 宽 (mm) | 高 (mm) | Processing power (t/h) | 有效容 积(m3) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MBY 0918 | 900 | 1800 | Y225M-8 | 22 | 730 | 4980 | 2370 | 2020 | 0.62~3.2 | 0.9 | 5700 |

| MBY 0924 | 900 | 2400 | Y250M-8 | 30 | 730 | 5670 | 3280 | 2020 | 0.81~4.3 | 1.2 | 5880 |

| MBY 1224 | 1200 | 2400 | Y280M-8 | 45 | 730 | 6450 | 2800 | 2500 | 0.4~4.9 | 2.28 | 12308 |

| MBY 1530 | 1500 | 3000 | JR125-8 | 95 | 725 | 7935 | 3185 | 2280 | 5 | 19990 | |

| MBYg 1530 | 1500 | 3000 | JR117-8 | 80 | 725 | 7253 | 3070 | 2280 | 2.4~7.5 | 5 | 21210 |

| MBYg 2130 | 2100 | 3000 | JR136-8 | 180 | 735 | 8122 | 4220 | 3073 | 14~35 | 9 | 42123.5 |

| MBYg 2136 | 2100 | 3600 | JR137-8 | 210 | 735 | 8958 | 4320 | 3025 | 43~61 | 10.8 | 45800.5 |

| MBYg 2430 | 2400 | 3000 | JR138-8 | 280 | 735 | 9004.5 | 4836.4 | 3490 | 11.5 | 55795 | |

| MBYg 2732 | 2700 | 3200 | JR157-8 | 320 | 750 | 10509 | 5000 | 3620 | 15.7 | 83110 | |

| MBYg 2736 | 2700 | 3600 | JR158-8 | 380 | 743 | 10764 | 5750 | 3620 | 32~86 | 17.7 | 90441 |

| MBY 2740 | 2700 | 4000 | TDMK400-32 | 400 | 187.5 | 12300 | 5700 | 4700 | 43~110 | 20.4 | 75000 |

| MBY 3040 | 3000 | 4000 | JR1510-8 | 570 | 740 | 9800 | 3900 | 3900 | 54~135 | 26 | 90000 |

| MBY 3245 | 3200 | 4500 | TDMK800-36 | 800 | 167 | 14600 | 7000 | 5300 | 64~180 | 31 | 113000 |

| MBY 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 150 | 15200 | 8800 | 6800 | 80~230 | 41.8 | 139000 |

| MBY 3654 | 3600 | 5400 | TDMK1600-40 | 1600 | 150 | 15900 | 8800 | 6800 | 100~250 | 49.7 | 150000 |