It has aeration, no slurry suction, mechanical stirring, large processing capacity and high mineral processing efficiency.

【Processing Capacity】:0.2~12m3/min

【Effective volume】:0.37~20m3

[Selected granularity]:0.3~0.01mm(-0.074mmGrain fraction content>50%)

【Application Environment】:It is suitable for sorting various metals and non-metallic minerals, and is mostly used in roughing and sweeping operations in medium and large flotation plants.

15311826613

Click to add WeChatThe KYF type inflatable flotation machine is a new type of equipment modified based on the OK type flotation machine. The flotation machine is a mechanical agitation flotation equipment that needs to be inflated and cannot self-prime slurry. It can be used alone or together with XCF type flotation machine constitutes a combined flotation unit and is used as a DC tank. It is configured horizontally and does not need to be equipped with a foam pump.

The external blower of the KYF flotation machine sends the air pressure required by the flotation machine into the hollow main shaft, and then blows it into the gap between the impeller blades through the internal air disperser. In this area, the slurry and air can be obtained Stir and mix thoroughly.

The mixed slurry is discharged upward to the upper half of the impeller. After being stabilized and oriented by the stator, it is dispersed throughout the tank of the flotation machine. Since the general inflatable mechanical agitation flotation machine presses in low-pressure air, it reduces the negative pressure in the center area of the impeller, making it difficult to absorb slurry.

The stator is an open stator with radial short blades suspended in the air, with a large radial gap between it and the impeller. The lower area of the stator has a large slurry flow area, which is conducive to the flow of slurry to the lower part of the impeller, reducing power loss and enhancing the strength of the lower part. Circulation in the circulation zone and suspension of solid particles.

Air is blown into the gap between the blades and the impeller through the air dispersion cover, so that the air can be evenly dispersed in most areas of the impeller blades in advance, providing a larger slurry-air contact interface, thereby improving impeller dispersion Ability.

Can start and stop under full load.

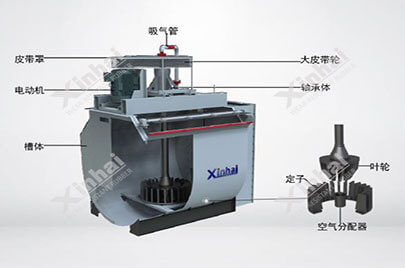

The structure of Kyf flotation machine mainly consists of tank body, bearing body, motor, belt cover, large pulley, suction pipe, stator, rotor, impeller and air distributor, etc.

The KYF type inflatable flotation machine will rotate with the impeller, so that the slurry in the tank is sucked from all sides through the bottom of the tank from the lower part of the impeller to between the blades. At the same time, the low-pressure air fed by the blower enters the air distributor through the air duct and the hollow shaft. After it flows into the blades and is fully mixed with the slurry, it is discharged from the edge of the upper half of the impeller. The discharged slurry moves obliquely upward. After being stabilized and oriented by the stator installed obliquely above the impeller, it is dispersed throughout the tank. The mineralized bubbles rise to the surface of the tank to form foam, and flow into the foam tank. The slurry returns to the impeller area for recycling, and the other part enters the lower tank through the flow hole on the wall between tanks for re-separation until it finally becomes tailings.

KYF type inflatable flotation machine packaging and delivery site

On-site installation of KYF type flotation machine in a project

On-site application of KYF type flotation machine project

| Model | Effective volume (m3) | Processing power (m3/min) | Impeller diameter (mm) | Impeller revolutions (r/min) | Blower air pressure (kPa ) | Maximum inflation amount (m3/m2-min) | Motor power for stirring (kW) | Scraper motor power (kW) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| KYF-1 | 1 | 0.2 ~1 | 340 | 281 | > 12.6 | 2 | 4 | 0.75 | 903 |

| KYF-2 | 2 | 0.4 ~2 | 410 | 247 | > 14.7 | 2 | 5.5 | 1.1 | 1419 |

| KYF-3 | 3 | 0.6 ~3 | 480 | 219 | > 19.8 | 2 | 7.5 | 1.5 | 1885 |

| KYF-4 | 4 | 1.2 ~4 | 550 | 200 | > 19.8 | 2 | 11 | 1.5 | 2206 |

| KYF-8 | 8 | 3.0 ~8 | 630 | 175 | > 21.6 | 2 | 15 | 1.5 | 3984 |

| KYF-10 | 10 | 4.0 ~10 | 630 | 192 | > 21.6 | 2 | 22 | 1.5 | 4406 |

| KYF-16 | 16 | 4.0 ~16 | 740 | 160 | > 25.5 | 2 | 30 | 1.5 | 5900 |

| KYF-24 | 24 | 4.0 ~24 | 800 | 150 | > 30.4 | 2 | 30 | 1.5 | 7500 |

| KYF-38 | 38 | 10.0 ~38 | 880 | 139 | > 34.3 | 2 | 45 | 1.5 | 10300 |