The dry magnetic separator produced by Xinhai Mining adopts a 360° magnetic wrap angle design, and the magnetic system adopts high magnetic energy product and high coercivity The powerful NdFeB magnet has high magnetic field strength and large depth of action. The demagnetization rate of the magnetic field strength does not exceed 5% in 8 years.

[Processing Capacity]:≤150t/h

[Ore feeding moisture content]:≤5% p>

[Application Environment]:Can be used for dry pre-selection of poor magnetite and rich iron ore before grinding, and re-selection of magnetic mineral tailings and the recovery operation of magnetic minerals in steel slag waste.

15311826613

Click to add WeChatXinhai Dry Magnetic Separator selects poor or rich magnetite with a particle size below 30mm before being fed into the mill. When pre-selecting rich magnetite, dry pre-selection of poor magnetite can discard a large amount of tailings. , the rich magnetite can be dumped in an appropriate amount to greatly improve the grinding grade.

During operation, it can quickly cause magnetic flipping and magnetic agitation of mineral particles to achieve efficient separation of magnetic minerals, non-magnetic and weakly magnetic minerals;

Dry magnetic separator can effectively solve the problem of eddy current heating and easy sticking. ore and difficulty in unloading the ore;

When the iron grade in the tailings is quite low, iron ore of different properties can be enriched by adjusting the corresponding technical parameters and structure;

The tailing rate is high, about 10~30% more tailings than conventional magnetic separators, and the dry concentration concentrate grade is increased by about 1.0%~8.7%;

When finely crushed to less than 2mm, embedded When the grain size of the cloth is coarse, qualified concentrate with a grade of more than 60% can be directly obtained;

The magnetic system is coated with non-magnetic stainless steel to ensure that the magnet does not fall off;

The sorting cylinder The body bag is covered with wear-resistant rubber, which significantly improves its service life.

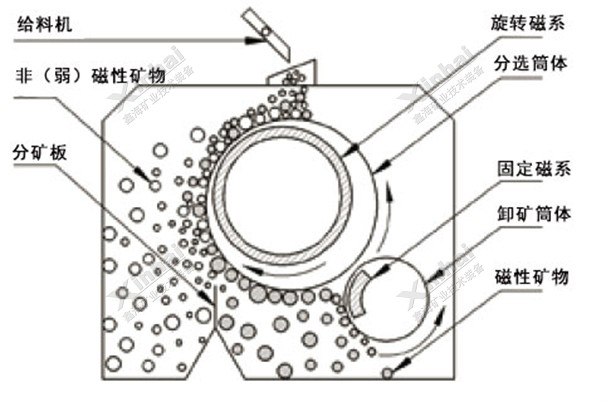

Xinhai dry magnetic separator is mainly composed of motor, cylinder support frame, sorting cylinder, ore unloading cylinder and other parts.

The working principle of the dry magnetic separator is that the centrifugal force and gravity experienced by the magnetic minerals in the classification area of the cylinder are much smaller than the magnetic force. The strong magnetic adsorption of the magnetic minerals, the combined effects of magnetic flipping and magnetic agitation , will gradually move toward the inner layer. When the magnetic minerals rotate with the sorting cylinder to the unloading area, since the rotating magnetic system is eccentrically arranged, the magnetic field intensity in the unloading area of the sorting cylinder is very weak, and most of the magnetic minerals It can automatically fall off. When the small amount of magnetic minerals that have not fallen off rotate to the vicinity of the unloading barrel, they are adsorbed to the outer surface of the unloading barrel with a higher magnetic field strength, thereby realizing automatic unloading of magnetic minerals.

| 规格Model | CTXG-0606 | CTXG-0812 | CTXG-0818 |

|---|---|---|---|

| Barrel diameter (mm) | 600 | 800 | 800 |

| Barrel length (mm) | 600 | 1200 | 1800 |

| Tube surface field strength (mT) | 300~500 | 300~500 | 300~500 |

| Feeding particle size (mm) | -30 | -30 | -30 |

| 给矿含水率 | ≤5% | ≤5% | ≤5% |

| Processing power(t/h) | ≤35 | ≤100 | ≤150 |

| Motor power(KW) | 5.5×2 | 11×2 | 11×2 |

| 总重(t) | 2.9 | 5.8 | 7.9 |

| 外形尺寸(mm) (长×宽×高) | 2700×1700×1900 | 3400×2000×2100 | 4200×2000×2100 |