15311826613

Click to add WeChatDue to its special structure, flake graphite ore is often separated by flotation. In order to effectively protect the flakes, in addition to selecting a suitable flotation process, the selection of mineral processing agents is also very important. During flotation, the hydrophobicity of graphite is improved by adding chemicals to improve the floatability of graphite. At present, the commonly used beneficiation agents for graphite mines include collectors, foaming agents and regulators. The following article will introduce them in detail!

Graphite itself has a certain degree of floatability, and graphite concentrate can float out without a collector, but its flotation effect is not Ideally, the recovery rate is not high. In order to further improve the graphite flotation efficiency, adding an appropriate amount of collector will make the flotation efficiency higher. Currently, the collectors available for graphite include kerosene, diesel, liquid paraffin, heavy oil and other hydrocarbon oils, etc. When used alone, the dosage is large.

In order to reduce the dosage of chemicals and at the same time ensure the flotation effect, relevant professionals have developed a variety of new chemicals, such as DF, MB- 25, MF, MB125, GB, etc. Among them, DF agent has fast flotation speed, is non-toxic and harmless, has little irritating odor, uses less amount, and has both foaming and collection functions; MB-25 is a non-polar compound agent that has both collection and collection functions. It is both non-toxic and foaming. This agent can reduce the adsorption thickness, increase the adsorption surface, and increase hydrophobicity. The thinner the adhesion layer of the agent on the mineral surface and the wider the coverage, the better it improves the hydrophobicity; MF collector is A combined agent made by mixing naphthenic acid, cracked diesel and diesel, which has good capture and selectivity, less dosage and lower price.

The role of the foaming agent is to increase the mechanical strength of the bubbles, prevent bubbles from merging, control the speed of bubbles floating, and change the distribution of bubbles. In graphite ore During flotation, commonly used frothers include 2# oil, cresolic acid, camphor oil, etc. Among them, 2# oil is frequently used. Its main component is terpene alcohol, with a general content of 40-60%.

In addition to 2# oil, there are also 4# oil, sec-octanol and MlBC, etc. The raw materials of 4# oil are easy to obtain, the price is low, the purity is high, the foaming ability is strong, and the bubble stability is good. However, 4# oil has a pungent smell; sec-octanol has strong foaming ability, bubble brittleness, and graphite. The recovery rate and flotation effect are significantly higher than pine alcohol oil (i.e. 2# oil); when MIBC is used as a foaming agent, the mineralized foam has better stability and selectivity. Compared with other agents, the dosage of graphite is less. The recovery rate is higher.

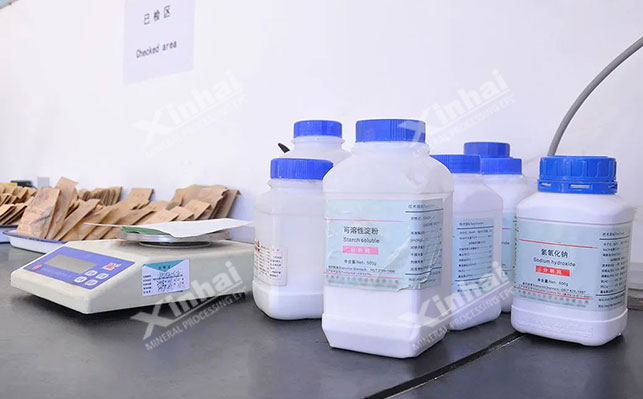

During graphite flotation, in order to better improve the graphite grade and recovery rate, a certain amount of regulator is added appropriately according to the properties of the slurry to adjust the PH of the slurry. values and ionic components, adjust the interaction between collectors and minerals, inhibit or enhance the hydrophobicity of minerals, etc. According to different functions, they are divided into: pH adjusters, inhibitors, dispersants, etc.

pH adjuster: Commonly used ones include lime, NaCO3, and Na(OH) 2, among which lime is a commonly used pH adjuster. When it comes into contact with water, it reacts with water to form Ca(OH)2, Ca (OH)2< /sub>Not easily soluble in water.

Inhibitors: water glass, sodium methylcellulose, EDTA, tartaric acid, citric acid and oxalic acid;

Dispersing agent: The function is to change the properties of the surface of mineral particles and enhance the suspension and stability of the slurry. Commonly used ones include water glass, sodium hexametaphosphate and sodium polyacrylate.

The above are the types of agents commonly used in flake graphite ore beneficiation. No matter which agent is used, attention should be paid to flotation when selecting At the same time, the characteristics of subsequent flotation operations should be taken into consideration in order to improve the operation effect. Agents should be selected that are small in dosage, non-toxic, beneficial to subsequent operations, degrade quickly, and are environmentally friendly.