15311826613

Click to add WeChatGraphite has the characteristics of high temperature resistance, strong electrical and thermal conductivity, so it has good applications in various fields. According to the characteristics of graphite ore, flotation is often used to complete the beneficiation. In the early stage, we have introduced the flotation process of graphite ore. This article will focus on the flotation equipment and reagents of graphite ore.

At present, there are many kinds of flotation equipment commonly used in graphite ore beneficiation. According to different types, they can be divided into three types: mechanical stirring flotation machine, aerated stirring flotation machine and combined flotation machine.

Mechanical stirring flotation machine: It mainly relies on impellers or mechanical stirrers for aeration and stirring.

Compressed air flotation machine: The flotation machine has no moving parts, and mainly relies on the external air to be pressed into it for aeration and stirring. The working principle of the flotation column is similar to this. This type of compressed air flotation machine works reliably, but its stirring capacity is weak and the reagent consumption is large.

Combined flotation machine: It is a combination of mechanical stirring and compressed air flotation machines. The impeller is mainly used to stir and distribute the slurry. The air intake is small and mainly supplied by the air compressor.

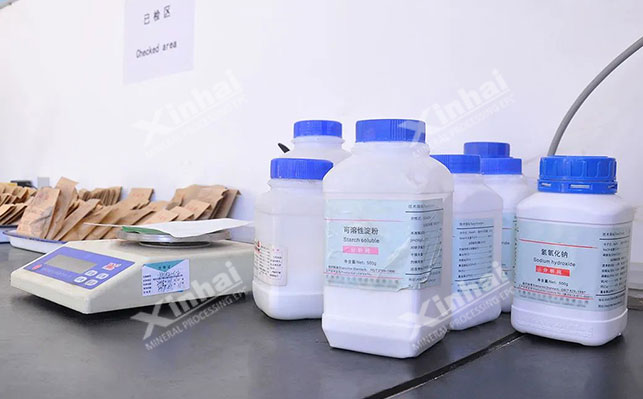

In the process of graphite ore flotation, the commonly used flotation reagents are collectors, foaming agents, regulators and surfactants.

Non-polar oil is a commonly used collector for graphite ore flotation, such as kerosene, diesel, heavy oil, etc. Among them, kerosene and diesel are the most widely used collectors in graphite ore dressing. They have good collection effect and low price. The collector of hydrocarbon oil is difficult to decompose and dissolve. The dosage required for flotation is large. It needs to be emulsified to reduce the dosage and improve the flotation efficiency. Common emulsification methods include aerosol method, ultrasonic method, mechanical stirring method, steam emulsification method, etc.

Frothing agents can make the foam more stable. Commonly used agents mainly include active substances such as alcohols, phenols, mail sulfonates and sulfates, such as No. 2 oil, No. 4 oil, etc. These agents can effectively improve the recovery rate and mineral processing efficiency of flotation.

The adjuster mainly plays the role of inhibition and activation, and is used for adjusting pH value, agglomerating and dispersing sludge, activating mineral surface, etc. Lime, sodium carbonate, sodium hydroxide, etc. are agents for adjusting the pH value of slurry. Water glass is a commonly used silicate mineral inhibitor, and commonly used activators are sodium petroleum sulfonate, sodium dodecyl sulfate, etc. If the graphite ore contains pyrite, lime is used as a pH adjuster.

The adhesion of hydrocarbon oil on the graphite surface is closely related to the wettability of the graphite surface. If there is a surfactant in the slurry, the surfactant molecules are arranged in a directional manner on the ore particles and the foaming surface, which is conducive to the adhesion of hydrocarbon oil on the ore particle surface and the foaming mineralization.

The above is a brief introduction to the flotation process, equipment and reagents of crystalline graphite and cryptocrystalline graphite ore. From the above, it can be seen that different types of graphite require different beneficiation methods for recovery. Xinhai Mining recommends conducting beneficiation tests to determine the characteristics of graphite ore, customizing the design of beneficiation plans and equipment, and improving beneficiation efficiency and economic benefits of the beneficiation plant.

Related recommendations: Graphite ore flotation purification