The aeration volume is large, the mixing particle size is strong, the bubble dispersion is high, the slurry, gas and chemicals are evenly mixed, and the flotation speed is fast.

【Processing Capacity】:1.5~4m3/min

【Effective volume】:1~4m3(customized according to needs)

[Slurry concentration]:<45%

【Application Environment】:It is suitable for the separation of minerals with heavy specific gravity, fast settling speed and coarse materials, especially for the separation of lead, zinc, molybdenum, sulfur and silica sand.

15311826613

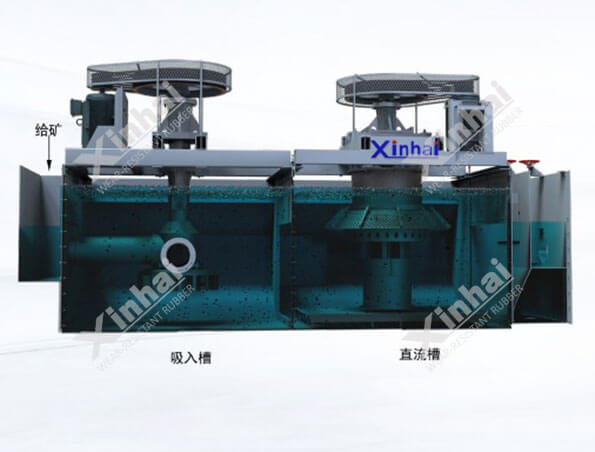

Click to add WeChatXJB rod flotation machineThere is DC tank and suction tank Two kinds.

DC tank:The main components such as hollow shaft, rod wheel, boss and arc-shaped flow stabilizing plate are installed inside. DC tank cannot self-prime slurry and only plays a flotation role.

suction tank:A suction wheel is installed at the bottom of the rod wheel, which can suck the slurry from the bottom like a centrifugal pump. Suction tanks must be installed at the pulp inlet points of rough selection, selection and sweeping operations.

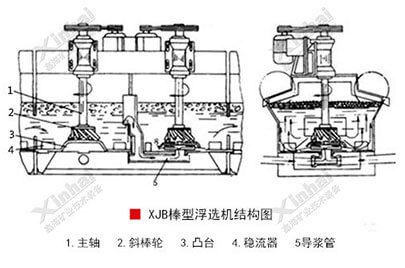

XJB rod flotation machine has a special flow stabilizing plate, which is composed of many arc-shaped blades of different lengths welded to the tank bottom lining plate, which can evenly distribute the slurry gas mixture throughout the tank and prevent the slurry from rotating in the tank;

When the XJB rod flotation machine impeller rotates, the speed of the inclined rod increases as it goes downwards, and the stirring force is very strong;

There is a boss and an arc-shaped flow stabilizing plate between the bottom of the flotation tank and the rod wheel. The boss acts as a guide, causing the slurry-gas mixture to quickly rush to the bottom of the tank. It moves around the tank body through the flow stabilizing effect of the arc-shaped flow stabilizing plate, and is evenly distributed in the tank with a W-shaped movement trajectory.

The main feature of the rod flotation machine is an inflatable agitator group composed of an inclined rod wheel, a boss, an arc-shaped flow stabilizing plate, etc. The impeller consists of 12 inclined cone rods and a circular composed of disks.

The working principle of the rod flotation machine is to use the negative pressure generated by the rotation of the impeller or rod wheel to suck air from the hollow shaft, and then the flotation wheel divides it to form tiny bubbles, which are then strongly stirred by the impeller or rod wheel. and ejection, so that the slurry and air are fully mixed. Under the action of the inclined rod of the flotation wheel, the useful mineral particles acted by the flotation agent (collector) selectively attach to the bubbles and float up. When it reaches the slurry surface, it is scraped into the concentrate tank by a scraper to complete the sorting operation.

Xinhai rod flotation machine installation site

Rod flotation machine packaging and delivery

XJB rod flotation machine Application site of a mineral processing plant

<img src="/uploads/product/fxuanjixc20.jpg" title="XJB rod flotation machine Application site of a mineral processing plant" width="" height="" alt="XJB rod flotation machine Application site of a mineral processing plant>

| Model | Slot type | Effective volume(m3) | Processing power(m3/min) | Impeller diameter(mm) | Impeller speed (r.p.m) | Motor power for stirring(kw) | Scraper motor power(kw)) | 4 tank weight (kg) |

|---|---|---|---|---|---|---|---|---|

| XJB-1 | suction tank | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5344 |

| XJB-1 | DC tank | 1 | 1.5-1.7 | 410 | 410 | 4 | 0.8 | 5344 |

| XJB-1D | suction tank | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5479 |

| XJB-1D | DC tank | 1 | 1.5-1.7 | 410 | 410 | 4 | 0.8 | 5479 |

| XJB-2 | suction tank | 2 | 1.5-1.4 | 450 | 360 | 15 | 1.1 | 9071 |

| XJB-2 | DC tank | 2 | 1.5-1.4 | 540 | 360 | 11 | 1.1 | 9071 |

| XJB-2D | suction tank | 2 | 1.5-1.4 | 450 | 360 | 15 | 1.1 | 9320 |

| XJB-2D | DC tank | 2 | 1.5-1.4 | 540 | 360 | 11 | 1.1 | 9320 |

| XJB-4 | suction tank | 4 | 2.0-4 | 700 | 280 | 18.5 | 1.1 | 16325 |

| XJB-4 | DC tank | 4 | 2.0-4 | 510 | 280 | 18.5 | 1.1 | 16325 |