15311826613

Click to add WeChatGold leaching is an important gold beneficiation process. It uses specific chemical reagents to dissolve the gold in the ore into a form containing A solution of gold is then extracted from the solution through further processing. The gold leaching process has the characteristics of high efficiency and good selectivity. It can extract gold from low-grade ores and improve the utilization rate of gold resources.

During the leaching process, the efficiency of gold leaching is affected by many factors, which can be mainly divided into four categories, namely ore properties, leaching reagents, leaching conditions and stirring intensity. Let’s learn about these influencing factors together.

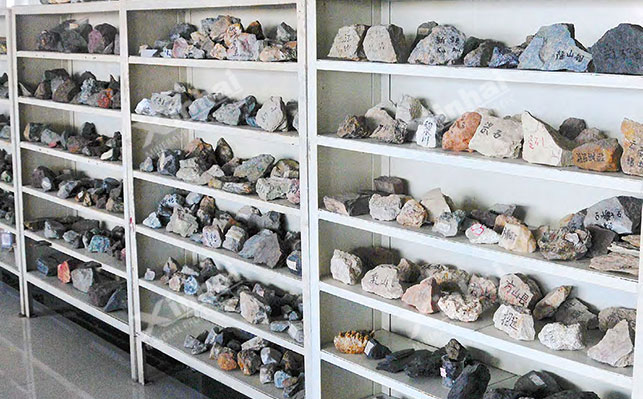

The physical and chemical properties of ore have a significant impact on leaching efficiency, including ore type, particle size, grade and mineral composition.

Different types of ores have different effects on gold leaching. Gold in oxide ores is usually easier to leach, while gold in sulfide ores requires pretreatment before leaching; the difficulty of leaching gold in mixed ores is between oxide ores and sulfide ores.

The impact of ore particle size on gold leaching is mainly reflected in two aspects. On the one hand, the smaller the particle size of the ore, the larger the contact area between gold and the leaching reagent, and the faster the leaching speed; on the other hand, the smaller the particle size of the ore, the greater the viscosity of the slurry, which affects the diffusion and mass transfer of the leaching reagent, thereby reducing leaching. speed.

The impact of ore grade on gold leaching is mainly reflected in the amount of leaching reagents and leaching time. The higher the grade of ore, the smaller the amount of leaching reagent required and the shorter the leaching time. On the contrary, the lower the ore grade, the greater the amount of leaching reagent required and the longer the leaching time.

The mineral composition in the ore also has a great influence on gold leaching. Some minerals such as pyrite, arsenic pyrite, etc. will react with the leaching reagent and consume the leaching reagent, thus reducing the gold leaching rate. In addition, some minerals such as quartz, feldspar, etc. will adsorb leaching reagents, affecting the diffusion and mass transfer of leaching reagents, thus reducing the leaching rate.

In the gold leaching process, reagents react with the gold through specific chemical reactions and then dissolve the gold from the ore to form a gold-containing solution. Reagents have many effects on gold, including: leaching reagent type, concentration, pH value, etc.

Different types of leaching reagents have different effects on gold leaching. Cyanide is currently the most widely used gold leaching reagent, with fast leaching speed, good selectivity and low cost. However, cyanide is toxic and very harmful to the environment and human health. Thiourea and chloride are also commonly used gold leaching reagents. They have better leaching speed and selectivity, but their costs are higher.

The influence of the concentration of leaching reagent on gold leaching is mainly reflected in the leaching speed and gold leaching rate. The higher the concentration of the leaching reagent, the faster the leaching speed and the higher the gold leaching rate. However, too high a concentration of leaching reagent will lead to increased costs and greater pollution to the environment. Generally, the cyanide concentration is controlled within the range of 0.05% to 0.1%.

The pH value of the leaching reagent also has a great impact on gold leaching. Different leaching reagents have different leaching effects at different pH values. Generally speaking, the reasonable pH value for cyanide leaching is about 10, the pH value for thiourea leaching is about 1.5, and the pH value for chloride leaching is 2 left and rights. In actual production, it is necessary to select the appropriate pH value of the leaching reagent according to the type of leaching reagent and the properties of the ore.

The influence of various leaching conditions on gold leaching mainly includes: leaching temperature, time and solid-liquid ratio.

The influence of leaching temperature on gold leaching is mainly reflected in the leaching speed and gold leaching rate. The higher the leaching temperature, the faster the leaching speed, and the higher the gold leaching rate. However, too high a leaching temperature will cause the decomposition and volatilization of the leaching reagent, increase costs, and also cause greater pollution to the environment. Therefore, in actual production, it is necessary to select an appropriate leaching temperature based on the properties of the ore and the requirements of the leaching process.

The impact of leaching time on gold leaching is mainly reflected in the gold leaching rate. The longer the leaching time, the higher the gold leaching rate. However, too long leaching time will increase costs and reduce production efficiency. Therefore, in actual production, it is necessary to select an appropriate leaching time based on the properties of the ore and the requirements of the leaching process.

The liquid-to-solid ratio refers to the ratio of the volume of the leachate to the mass of the ore. The influence of liquid-to-solid ratio on gold leaching is mainly reflected in the leaching speed and gold leaching rate. The larger the liquid-to-solid ratio, the faster the leaching speed and the higher the gold leaching rate. However, an excessive liquid-to-solid ratio will lead to an increase in the dosage of leaching reagents, an increase in costs, and will also increase the difficulty of subsequent processing. Therefore, in actual production, it is necessary to select an appropriate liquid-to-solid ratio based on the properties of the ore and the requirements of the leaching process.

The influence of stirring intensity on gold leaching is mainly reflected in the leaching speed and gold leaching rate. The greater the stirring intensity, the faster the leaching speed, and the higher the gold leaching rate. This is because stirring can make the leaching reagent fully contact with the ore, increase the diffusion and mass transfer speed of the leaching reagent, and thereby speed up the leaching speed. However, excessive stirring intensity will cause the temperature of the slurry to rise, accelerate the decomposition and volatilization of the leaching reagent, and also increase equipment wear and energy consumption. Therefore, in actual production, it is necessary to select the appropriate stirring intensity according to the properties of the ore and the requirements of the leaching process.

In actual production, it is necessary to select appropriate leaching reagents and leaching conditions according to the nature of the ore and the requirements of the leaching process, and control the stirring intensity to improve the efficiency of gold leaching and the leaching rate of gold, reduce production costs, and reduce environmental impact. pollution, so it is recommended to conduct mineral processing test and determine the leaching conditions through experimental analysis.