15311826613

Click to add WeChatWith the rapid development of new energy vehicles, the global demand for lithium resources continues to rise, resulting in a shortage of lithium resources. Lithium-rich ores are the main source of lithium. So, what are lithium-rich ores? What are the beneficiation technologies for lithium-rich ores?

At present, about 35% of the world's lithium resources come from lithium-rich minerals, mainly spodumene, lepidolite and lithium aluminum phosphate.

Spodumene crystals are often columnar, granular or plate-shaped, mainly found in lithium-rich granite pegmatites, with a monoclinic crystal structure.

Lepidolite belongs to the monoclinic system and is a TOT layered silicate mineral. It is generally produced in the form of flaky or scaly aggregates and is mainly found in granite pegmatites. It is rose or lavender in color, has a continuous layered silicon-oxygen tetrahedral structure, and the layered cleavage is very complete.

Lithium aluminum phosphate is a fluorophosphate containing lithium and aluminum. It is produced in granite pegmatite and is often in the form of a dense block aggregate. It belongs to the triclinic system. Aluminum atoms and oxygen atoms form an aluminum-oxygen octahedral structure.

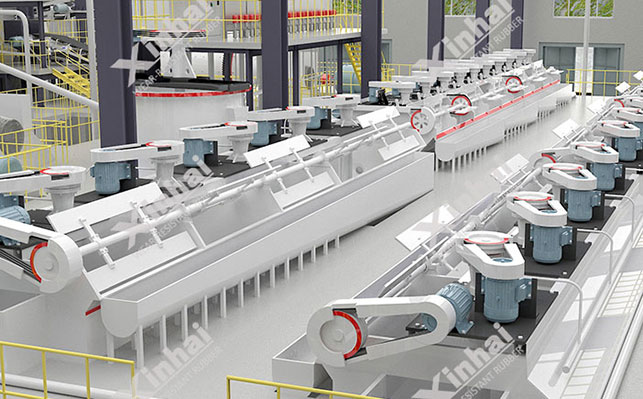

There are two common methods for spodumene dressing: flotation and chemical leaching.

Flotation method: Flotation method has wide applicability and is widely used in the purification of industrially valuable spodumene. However, flotation reagents are one of the key factors affecting the flotation effect of spodumene. Therefore, efficient and environmentally friendly collectors can be selected. For example, sodium oleate/tributyl phosphine chloride can be used to float spodumene from feldspar. New mixed anion and cation collectors can achieve better flotation separation effects. In addition, adding a small amount of cationic collector dodecylamine hydrochloride (DDA) during flotation can significantly enhance the ability of anionic collector sodium oleate to separate spodumene from feldspar.

Chemical leaching: Chemical leaching is one of the common methods for purifying spodumene, but the ore needs to be pretreated, specifically activation treatment. Destroying the aluminosilicate structure is the key to extracting lithium from spodumene by chemical leaching. Since spodumene is similar to illite, the Bayer process can be introduced to treat natural α-spodumene. The ore decomposes under alkaline conditions, and adding calcium oxide and increasing the temperature can accelerate the decomposition of spodumene. After optimization, the lithium leaching rate can be increased to about 93%.

The main method for extracting lithium from lepidolite is chemical leaching, and different chemical agents can produce different leaching rates. When potassium sulfate is used as an activator, the structure of lepidolite does not change much, and the lithium leaching rate can reach 98.7%. If potassium salt is used as an activator, combined with ball mill grinding, the lepidolite leaching rate can reach 99.1%. Therefore, it is necessary to select a suitable type of activator and its mass ratio with the concentrate. At the same time, the ball mill speed, grinding time, reaction temperature, stirring speed, etc. are all factors that affect the chemical leaching effect of lithium mica.

Lithium phosphate aluminum ore is mainly processed by flotation due to its special mineral properties. When lithium concentrate is obtained by flotation for leaching, it is necessary to first perform ball mill pretreatment and then leach with concentrated sulfuric acid. Concentrated sulfuric acid can convert lithium and aluminum into soluble sulfates, extract fluorides and phosphates, and obtain enriched leachate. By adding limestone, lime, monovalent carbonate or hydroxide, acidic impurities can be precipitated, impurities in lithium-containing filtrate can be removed, and lithium can be recovered in the form of lithium-containing salt products.

The above is an introduction to the three types of lithium-rich ores and their respective beneficiation process. In actual beneficiation plants, due to the different mineralization conditions and ore properties of lithium ores, simply copying and applying similar process flows is likely to reduce the recovery rate and return on investment of lithium concentrate. Therefore, it is recommended to conduct beneficiation tests first, and design a reasonable lithium ore beneficiation process through experimental analysis.