15311826613

Click to add WeChatQuartz sand (also known as silica sand) is a non-metallic mineral that needs to be purified through mineral processing to obtain high-quality quartz sand, which is then used in various industries. What are the commonly used equipment for quartz sand mineral processing and purification? This is mainly based on the mineral processing process. The general process is crushing and screening, grinding and classification, separation and dehydration. The equipment is crusher, screener, grinder, classifier, dehydration equipment, magnetic Select equipment, etc. Let’s find out together below!

Crushing is the primary stage of decomposing quartz sand ore, which is generally used to crush large ores after mining. The blocks are fed into the crusher for crushing to obtain smaller particles. The main equipment used in this stage includes jaw crusher, hammer crusher, and cone crusher. Among them, jaw crusher is mostly used for coarse crushing in the first crushing stage; Hammer crusherusually performs medium crushing operations; Cone crusher often performs fine crushing operations in the second or third stage operation.

The screening operation in the quartz sand production line process is completed in conjunction with crushing to complete the crushing and screening work. When large particles of ore are crushed and discharged , will be screened by the screening machine first, and the qualified particles will enter the next mineral processing link, while the larger particles will be returned to the crusher by the belt conveyor for further crushing. The main equipment used in this stage is circular vibrating screen, self-centering vibrating screen, and linear vibrating screen. Among them, circular vibrating screen is used for material particle size classification; self-centering vibrating screen is suitable for classifying medium and fine-grained minerals; linear vibrating screen Suitable for dehydration, desliming, deliquidation and removal of heavy media.

The quartz sand ore particles that have passed through the crushing and screening stage will enter the grinding process. Through the action of ball mill or rod mill equipment, the quartz sand ore particles are ground into powder to meet the optional particle size requirements. During the grinding process, impurities (such as thin film iron, mud, etc.) on the mineral surface need to be scrubbed away from the ground product using a scrubber. The equipment used in this stage includes wet rod mill, grid ball mill, overflow ball mill, etc. Among them, in addition to completing the grinding operation, the rod mill can also play a scrubbing role to a certain extent to remove impurities; the grid ball mill is mainly used for rough grinding and is often used in one-stage grinding; the overflow ball mill is mainly used for Fine grinding is mostly used in the second-stage grinding operation.

Grading is mainly coordinated with grinding. In order to ensure that the grinding particle size meets the separation requirements, in After grinding, it is sent to the classifier for classification. The coarser particles are returned to the ball mill for re-grinding, while the qualified particles enter the next step. The equipment used in this stage includes spiral classifier, hydrocyclone and hindered settler. Among them, the spiral classifier is used for coarse particle classification and is often used in conjunction with the grid ball mill; the hydrocyclone is used for fine particle classification and is often used in conjunction with the overflow ball mill. If a rod mill is used for grinding, it needs to be determined according to the process plan. Type of classifier; the hindered settler is a device that interferes with sedimentation. The material is affected by the rising water flow in the barrel to achieve the purpose of particle size classification and specific gravity separation. It has high production efficiency and low energy consumption.

Quartz sand sorting equipment is determined according to the process plan. Common plans include scrubbing, magnetic separation, flotation, and gravity selection. And pickling several kinds.

Quartz sand scrubbing production line equipment:There are two types of scrubbing machines: spiral scrubbing and stirring scrubbing. When dealing with coarser particles, you can choose Spiral scrubber, if the mud content is high, it is better to choose Agitator scrubber.

Quartz sand magnetic separation production line equipment: Magnetic separation is mainly used to remove strong magnetic and weak magnetic impurity minerals present in quartz. The equipment mainly includes wet strong magnetic separator, high gradient magnetic separator, weak magnetic separator (medium magnetic separator), etc. Among them, wet strong magnetic separators are mostly used to remove weak magnetic minerals such as hematite, limonite and biotite present in quartz sand; high gradient magnetic separators are often used in secondary magnetic separation operations, or to process some weak magnetic minerals. Minerals, such as amphibole, pyroxene, and conjoined bodies of magnetic minerals and quartz, etc.; weak magnetic separators are mostly used to remove magnetite in quartz sand, which is a strong magnetic separation of iron minerals.

Quartz sand flotation production line equipment:Flotation is used to remove feldspar and mica present in quartz Methods such as non-magnetic associated impurity minerals. The main equipment used is mechanical agitation flotation machine and inflatable agitation flotation machine. Among them, mechanical agitation flotation machines include SF type flotation machine, There are several JJF type flotation machines and BF type flotation machines; there are several types of inflatable agitation flotation machines: XCF type flotation machine, KYF type flotation machine, CLF type, BSK type, BSF type and XHF type. , in the actual mineral processing process, it can be used in combination with multiple types, or it can be used in combination with one type of flotation machine, depending on the process.

Quartz sand gravity separation production line equipment: When there are a small amount of heavy mineral impurities in the quartz sand raw material, the minerals with larger specific gravity need to be separated from the quartz sand through gravity separation. The equipment selected at this stage is mainly a spiral chute, which uses the water flow in the chute for sorting. The slurry is fed into the chute with a certain inclination. Under the action of the impulse of the water flow, the gravity and centrifugal force of the ore particles, and the friction force The mineral particles are stratified according to density.

Quartz sand pickling production line equipment: There is still a certain amount of iron in the quartz sand concentrate after separation. In order to better purify impurities, the pickling method can be used. Generally, the components and impurities are removed by washing with water first, and then soaked in water with pickling to obtain the product for drying or air-drying. The main equipment used is the pickling tank and various pickling chemicals.

The dehydration link is to dehydrate the quartz sand concentrate obtained after sorting, and then facilitate subsequent smelting. Commonly used equipment at this stage include concentrators, dewatering screens, filter presses and filters. Among them, the concentrators are mostly inclined plate concentrators, which are similar to dewatering screens and are suitable for concentrating and dehydrating fine-grained quartz sand; filter presses and filters are mostly used in the final stage of dehydration to keep the moisture content below 15%.

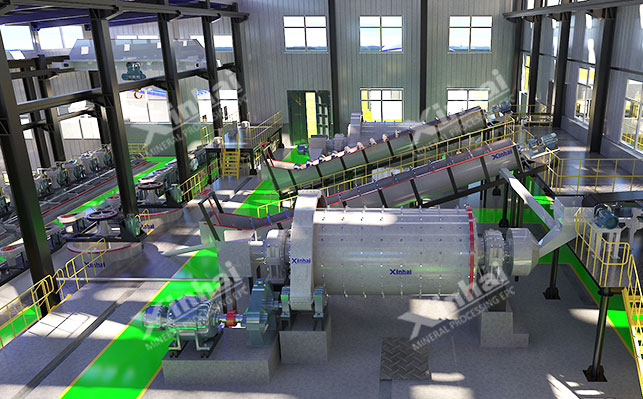

Xinhai Mining is a mining enterprise that provides services throughout the mining industry chain. We can conduct beneficiation tests on quartz sand ore samples, and design suitable quartz sand beneficiation process plans, quartz sand beneficiation plant construction plans and complete sets of quartz sand beneficiation plants based on the data. Sand production line equipment, this kind of general contracting form is more cost-effective, and the mineral processing plant can be put into production quickly and get return on investment as soon as possible. If you have any needs, please feel free to consult.