15311826613

Click to add WeChatAs one of the most common minerals in the earth's crust, quartz sand is widely used in industries such as glass, ceramics, and metallurgy. However, natural quartz ore is usually accompanied by a large amount of impurities. In order to improve the purity of quartz, it must be processed by flotation and other mineral processing processes. In the process of quartz sand flotation, factors such as particle size control, slurry concentration, foam properties, water quality, temperature, and flotation equipment will directly affect the flotation effect. Reasonable control of these parameters can effectively improve the efficiency of the flotation process and maximize the purity and recovery rate of quartz.

The quartz sand flotation process requires strict control of the ore particle size. Generally speaking, the flotation capacity of minerals is different with different particle sizes. When the mineral particles are large, the bubbles generated by the flotation agent will not have enough carrying capacity for the mineral particles, causing flotation difficulties. If the mineral particles are small, although the bubbles have sufficient carrying capacity for the mineral particles, it will affect the final grade of the mineral, reduce the grade of the mineral, and fail to obtain a good flotation effect. Therefore, particle size control is an important process of quartz sand flotation. Long-term practice has proved that it is appropriate to control the particle size of mineral particles between 0.01-0.25mm.

The adjustment of slurry concentration is a key link in the flotation process of quartz sand, which directly affects the flotation effect and the purity of the final product. When flotating quartz, the slurry concentration usually needs to be maintained between 34% and 40%. This concentration range helps to ensure the proper dispersion of mineral particles so that quartz and impurity minerals can effectively contact. At the same time, a higher slurry concentration can increase the sedimentation rate of minerals in the flotation tank, thereby speeding up the processing efficiency. However, too high a slurry concentration may cause particle agglomeration, affect the stability of the flotation foam, and reduce the selectivity and recovery rate of flotation.

Quartz sand foam flotation is mainly a process of gas-liquid interface separation. Reasonable and effective control of the size of flotation foam, the structure of foam, the thickness of the foam layer and the stability of foam can better improve the flotation efficiency. Appropriate foam size can increase the chance of mineral particles attaching and ensure a better capture rate. A uniform and stable foam layer is conducive to the dispersion of minerals and increases the probability of contact.

In addition, the thickness of the foam layer is also very important. Too thick foam can easily cause foam overflow or precipitation, and too thin foam cannot effectively capture minerals. Therefore, it is very important to maintain a moderate foam layer thickness.

In addition, foam stability can prolong the residence time of minerals, thereby improving the recovery rate. Reasonable adjustment of flotation reagents and operating conditions will help improve the properties of foam and further improve the overall efficiency of quartz flotation.

In the flotation process, there are two main purposes of controlling temperature: one is to provide a suitable environment for the action and reaction of reagents, because different reagents require different suitable temperatures for reaction; the other is that the flotation separation of some minerals needs to be carried out at a suitable temperature. According to mineral processing practice, when the pulp temperature is set at 40-45℃, the quartz flotation effect is good.

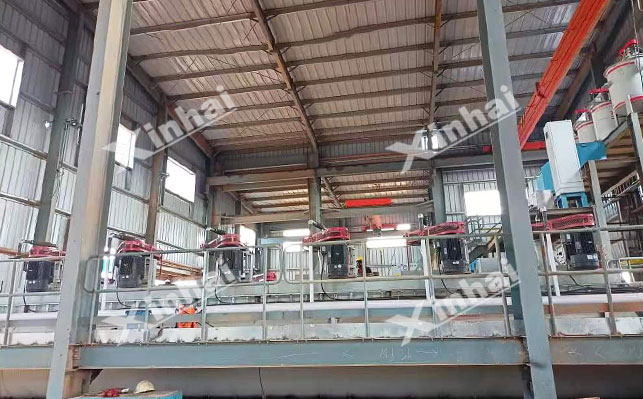

There are many types of flotation machines, which can be mainly divided into aerated agitation flotation machine, aerated flotation machine, mechanical agitation flotation machine and other categories. Since silica contains many impurities such as feldspar, mica, and iron-containing minerals in addition to quartz, feldspar and mica must be removed first when flotating silica. Quartz flotation generally uses a mechanical stirring flotation machine. This type of equipment can not only aerate the slurry, but also stir it at the same time, which has great advantages for multi-stage flotation, thereby improving the flotation effect.

In summary, the quartz sand flotation process is a complex process involving multiple factors. From the control of mineral particle size to the stability of foam, to the selection of equipment, each link has an important impact on the flotation results. By optimizing the key parameters in the flotation process, the purity of quartz can be effectively improved to meet the industry's demand for high-quality quartz products. With the continuous advancement of technology, the future quartz flotation process will be more refined and efficient, providing stronger support for the development of related industries.