15311826613

Click to add WeChatWhen the purity of SiO2 (quartz sand) is higher than 99.9%, it can be called high-purity quartz sand. The chemical properties of quartz sand are stable. Except for HF, it is insoluble in other acids and slightly soluble in KOH solution. In the early days, quartz sand was used as the main raw material for producing crystals. Now it can be widely used in the production of glass, optical fiber, solar cell substrates, abrasives, coatings and other industries.

When quartz sand is used as the above-mentioned raw material, it needs to be purified first. So what are the high-purity quartz sand purification equipment in the selection plant? Let's learn about it together. According to the customization of the quartz sand beneficiation process, the commonly used equipment mainly includes pre-selection equipment, beneficiation pretreatment equipment and post-selection dehydration equipment, etc.

Before the general quartz sand enters the selection and purification stage, it must first be crushed and ground to meet the particle size requirements for selection. The crushing stage is to initially crush the mined quartz sand ore into a certain ore block, and then feed it into the grinding stage for fine grinding.

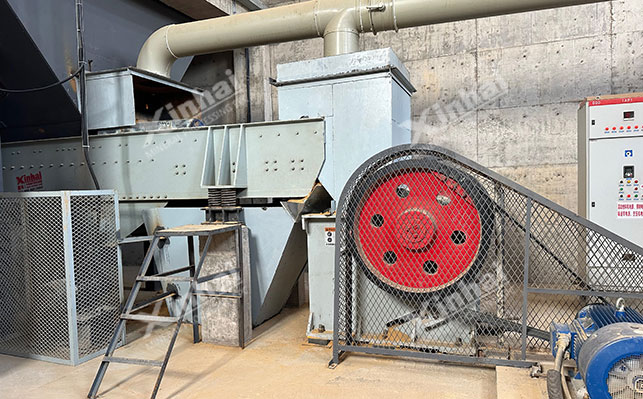

The quartz sand crushing stage is divided into two parts: crushing and screening. The process can have two schemes: one-stage closed-circuit crushing and two-stage closed-circuit crushing. The raw ore is fed to the crusher by the feeder for primary crushing, and the crushed product is fed to the vibrating screen for screening. The screened material is returned to the crusher by the belt conveyor for further crushing, and the screened material enters the grinding stage. The crushing and screening equipment required in the process include jaw crusher (coarse crushing), cone crusher (fine crushing), linear vibrating screen or multi-layer vibrating screen, etc.

The grinding stage is divided into two parts: grinding and classification. According to the requirements of the particle size for the selection, a rod mill is usually used to complete the grinding. For classification, a hydrocyclone or a spiral classifier is selected according to the particle size requirements. The process is usually that the crushed mineral is fed into the storage bin, and then fed into the rod mill for grinding through the feed truck. The ground mineral is fed into the classifier for classification, and the overflow returns to the rod mill for re-grinding, and the bottom flow enters the next link.

This stage of processing quartz sand is the purification stage. Usually, quartz sand ore dressing is purified by ore washing and desludging, magnetic separation, gravity separation, flotation and acid washing according to its ore dressing requirements and the requirements of the ore dressing plant.

Ore washing is an essential part of the quartz sand beneficiation process. The main reason is that there are many impurities in quartz sand, and the grade of different impurities is closely related to the particle size of quartz sand. If the quartz sand is not washed and impurities are removed before selection, the purity of quartz sand will be seriously affected. When washing quartz sand, the commonly used equipment is mainly scrubbing machine. Auxiliary agents can also be added during the scrubbing process to change the particle size composition of mineral particles to improve the scrubbing operation and improve the impurity removal efficiency. There are two options for scrubbing machines that can be used in the process: trough scrubbing machine and stirring scrubbing machine.

Magnetic separation and purification of quartz sand is mostly because there are some weakly magnetic impurities in the quartz sand mineral, such as hematite, limonite, biotite and other minerals. These impurities are the main source of the whiteness of the applied quartz sand. Therefore, the iron-containing impurities can be removed by magnetic separation. For strongly magnetic minerals, weak magnetic separation can be used for separation, and the required equipment is a weak magnetic separator or a medium magnetic machine; for weakly magnetic minerals, strong magnetic separation is required, and the required equipment is a strong magnetic separator of more than 1t.

Gravity separation and purification of quartz sand is based on the density difference between quartz sand and other minerals. The difference in relative density "particle size" shape between mineral particles and the difference in movement speed and direction in water or air and heavy suspension are used to separate impurity minerals from quartz sand. The equipment required in the process of gravity separation of quartz sand mainly includes jigging machine, shaking table, spiral chute and spiral concentrator.

Flotation purification of quartz sand is mostly used to treat mineral particles such as biotite, garnet and amphibole in quartz sand minerals. At present, the flotation of quartz sand is mainly completed under acidic conditions using suitable mineral processing agents. According to the different selection of agents, there are two methods: fluorine flotation and fluorine-free flotation. The flotation equipment required for this link includes XCF flotation machine, KYF flotation machine, SF flotation machine, JJF flotation machine and BF flotation machine. The specific selection depends on the conditions of the ore dressing plant and the investment cost.

Pickling is an important link in purification. When the purity of quartz sand is required to be high, pickling treatment is required. There are two types: acid leaching and alkali leaching. Among them, the acids commonly used for acid leaching include sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid, etc.; alkaline solutions such as sodium hydroxide or sodium carbonate are commonly used for alkali leaching, which can effectively dissolve aluminum silicates, thereby achieving the purpose of purification. The equipment used in this link is mainly pickling tanks and various pickling agents.

The dehydration operation is mainly to concentrate and dehydrate the quartz sand slurry after selection, so that its water content is low enough for smelting. The process is to customize suitable dehydration equipment according to the dehydration requirements, and dehydrate step by step to finally achieve a water content of less than 20%. Commonly used equipment mainly includes high-efficiency concentrator, high-frequency dehydration screen, chamber filter press, filter and other equipment.

The above is an introduction to high-purity quartz sand purification equipment. In actual ore dressing plants, quartz sand purification needs to be customized according to the user's requirements for purification. Suitable ore dressing processes and equipment are also required in combination with the characteristics of quartz sand ore properties. Therefore, it is recommended to conduct ore dressing tests, design suitable quartz sand purification processes through test analysis, and customize suitable quartz sand purification equipment to obtain ideal high-purity quartz sand concentrates.