15311826613

Click to add WeChatZinc oxide is an important mineral for obtaining zinc resources, but due to its complex ore properties, fine embedded particle size, severe mud, high soluble salt content, and a wide variety of minerals, which are mixed and associated with each other, the beneficiation is difficult. Therefore, the selection of flotation process is very important, and the selection of reagents is also very important. The following article will focus on what are the commonly used beneficiation reagents for zinc oxide beneficiation?

The commonly used mineral processing agents in zinc oxide flotation are mainly collectors and regulators.

At present, in the process of zinc oxide flotation in the ore dressing plant, the commonly used collectors are mainly fatty acids, amines and xanthates, among which fatty acids mainly include oleic acid, tall oil, oxidized paraffin soap, etc.; xanthates generally use advanced xanthates; and amines are mostly fatty amines. According to different classifications, it can be divided into cationic collectors, anionic collectors, chelating collectors and combined collectors.

Zinc Oxide Anionic Collector: The anionic collectors used in zinc oxide flotation are mainly xanthate collectors, hydroxamic acid collectors, carboxylic acid collectors, thiol collectors, etc.

Zinc oxide cation collector: Amine collectors are the main cation collectors, such as octadecylamine and dodecylamine, which are common collectors for flotation of zinc oxide ore.

Zinc oxide chelate collector: It can react with metal ions on the surface of the mineral to form insoluble chelates, thereby achieving the effect of capturing the target mineral. For example, E-5 modified alkylamine zinc oxide chelate collector has the advantages of small dosage, low price, strong capture power and good selectivity. It is applied in industrial production to re-float the zinc oxide minerals in the tailings after gravity separation, and the zinc concentrate product indicators with a grade of 32% and a recovery rate of about 85% can be obtained.

Zinc oxide combined collector: is a combination of anionic and cationic collectors, that is, the combination of amine collectors and xanthate collectors or carboxylic acid collectors.

The adjuster can improve the selectivity of the flotation process, strengthen the effect of the collector and the mineral, improve the conditions of the pulp, and have an important impact on the flotation of zinc oxide. According to the different functions of each agent, it is divided into pH adjusters, activators, inhibitors, flocculants, dispersants and foaming agents.

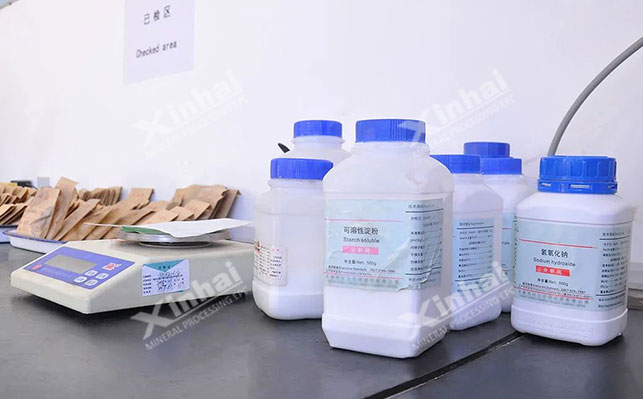

Zinc oxide pH adjuster:Generally, it is sodium hydroxide, sodium carbonate, sodium sulfide. Sodium sulfide is often used in the amine method, and its role is multifaceted.

Zinc oxide sulfiding agent: Common sulfiding agents are used to sulfidize the surface of zinc oxide minerals, represented by Na2S and NaHS.

When dodecylamine is used as a collector for smithsonite flotation, five organic chelating agents, namely salicylaldehyde oxime, a-benzoin oxime, anthranilic acid, 8-hydroxyquinoline and ethylenediamine, are also good activators.

Zinc oxide activator: There are many types of activators. The main purpose of using activators is to enhance the adsorption capacity of zinc oxide mineral particles on the surface of the collector. During flotation, the four inorganic salts of ammonium chloride, ammonium nitrate, ammonium sulfate and ammonium bicarbonate promote the flotation of smithsonite.

Zinc oxide inhibitor/dispersant: Quartz, dolomite, calcite, iron oxide clay and iron hydroxide constitute the main gangue minerals of zinc oxide ore. These impurity minerals seriously affect the resources of zinc oxide ore. Depressants such as sodium hexametaphosphate, water glass, sodium humate, starch glue, and methyl cellulose can be used to prevent limonite from floating up with smithsonite. In zinc oxide flotation, BD2 and sodium hexametaphosphate are used as depressants, which have strong selectivity in roughing operations. They can not only inhibit gangue minerals such as limonite, calcite and quartz, but also increase the floating rate of zinc oxide minerals.

Zinc oxide flocculant: Before flotation, the gangue or target mineral is selectively flocculated to form larger particles for precipitation and separation, and then the collector is added to float the useful minerals. This is the role of the flocculant. For fine mud, use efficient selective flocculant KN, and then carry out sulfide-amine flotation on the concentrate after flocculation and sedimentation to obtain better zinc concentrate.

Zinc oxide frother: The main components of the frother are various alcohols, such as the composite new frother-No. 4 oil, which is a brown oily liquid with good fluidity and no special irritating odor.

The above are the types of ore dressing agents commonly used in zinc oxide ore dressing plants. In actual ore dressing, the selection and dosage of the agents need to be determined according to the flotation process plan. Therefore, the editor recommends that the appropriate type of ore dressing agent and the dosage of the ore dressing agent should be customized through ore dressing test analysis to obtain the ideal zinc concentrate grade.