Self-priming, self-priming slurry, mechanical stirring, large processing capacity, and high mineral processing efficiency.

【Processing Capacity】:0.2~12m3/min

【Effective volume】:0.37~20m3

【Application Environment】:It is suitable for sorting various metals and non-metallic minerals, and is mostly used in roughing and sweeping operations in medium and large flotation plants.

15311826613

Click to add WeChatXinhai SF type flotation machine is a mechanical agitation flotation machine that self-primes and self-primes slurry. Each tank has three functions of air suction, slurry suction and flotation. It forms a self-contained flotation circuit and does not require any auxiliary equipment. The flotation machine operation unit can be configured according to actual needs and connected in parallel to form multiple tanks. It can also be combined with the JJF type flotation machine to form a joint flotation unit to serve as the suction tank for each operation. The SF type flotation machine should be configured horizontally to facilitate process changes.

The impeller of the flotation machine is equipped with backward-inclined double-sided blades, which can realize double circulation of the slurry in the tank; the gap between the impeller and the cover plate is large, and the air suction volume is large; the impeller peripheral speed is low and easy to Damaged parts have long service life.

The forward-inclined tank design of the flotation machine makes the dead space in the tank small and the foam movement speed is fast;

The air suction volume is large and the energy consumption is small;< /p>

The wearing parts have long service life;

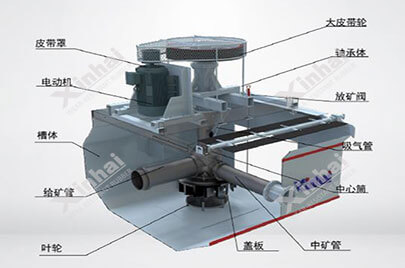

Sf flotation machine is composed of motor, tank body, ore feeding pipe, impeller, cover plate, medium ore pipe, center cylinder, suction pipe, bearing, pulley and other parts. Among them, the impeller of the SF flotation machine uses backward-inclined double-sided blades, which can realize double circulation of slurry in the tank; the gap between the impeller and the cover plate is designed to be large, which can effectively ensure the air suction volume of the flotation machine; the forward-inclined tank The body has a small dead space and the foam moves quickly.

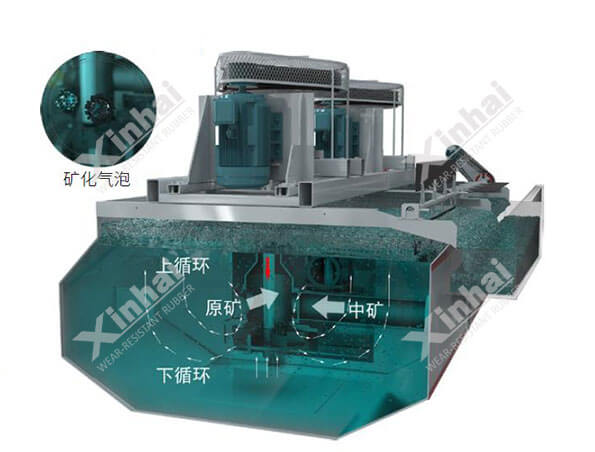

When the impeller of the SF type flotation machine rotates, the slurry in the upper and lower impeller cavities generates centrifugal force under the action of the upper and lower blades and is thrown around, forming a negative pressure zone in the upper and lower impeller cavities. At the same time, the slurry in the upper part of the cover plate passes through the cover plate. The circulation hole is sucked into the upper impeller cavity to form an upper circulation of slurry. When the lower blade throws out the slurry to the surroundings, the lower part of the slurry is replenished towards the center, thus forming a lower circulation of the slurry. The air is sucked into the upper impeller cavity through the suction pipe and the central cylinder. The air mixes with the sucked slurry to form a large number of fine bubbles. After passing through the cover plate to stabilize the flow, it is evenly dispersed in the tank to form mineralized bubbles and mineralization. The bubbles float up to the foam layer and are scraped out with a scraper to become a foam product.

SF type flotation machine is being shipped

On-site installation and commissioning of SF type flotation machine project

Application of Xinhai SF flotation machine in a project

| Model | Effective volume (m3) | Processing power (m3/min) | Impeller diameter (mm) | Impeller revolutions (r/min) | Motor power for stirring (kW) | Scraper motor power (kW) | Single tank weight (kg) |

|---|---|---|---|---|---|---|---|

| SF-0.37 | 0.37 | 0.2~0.4 | 300 | 352~442 | 1.5 | 0.55 | 468 |

| SF-0.7 | 0.7 | 0.3~1.0 | 350 | 336~384 | 3 | 1.1 | 629 |

| SF-1.2 | 1.2 | 0.6~1.6 | 450 | 312 | 5.5 | 1.1 | 1373 |

| SF-2 | 2 | 1.5 ~3 | 550 | 280 | 11 | 1.5 | 1879 |

| SF-2.8 | 2.8 | 1.5~3.5 | 550 | 280 | 11 | 1.5 | 1902 |

| SF-4 | 4 | 2.0 ~4 | 650 | 235 | 15 | 1.5 | 2582 |

| SF-6 | 6 | 3~6 | 760 | 191 | 30 | 2.2 | 3540 |

| SF-8 | 8 | 4.0 ~8 | 760 | 191 | 30 | 2.2 | 4129 |

| SF-16 | 16 | 5.0 ~16 | 850 | 169~193 | 45 | 1.5 | 7415 |

| SF-20 | 20 | 10 ~12 | 850 | 169~193 | 45 | 1.5 | 9828 |