The Uganda phosphate ore project undertaken by Xinhai Mining is a service project for the entire mining industry chain. Through mineral processing tests, it has provided mature and reliable mineral processing processes and mineral processing equipment, ensuring the long-term, safe, stable and continuous operation of the mineral processing plant. run on ground.

720t/d

Flotation machine, cyclone, ball mill, stirring tank

Desliming - one stage of closed-circuit grinding - one coarse, one sweep and two fine flotation - fine tailings dehydration process flow.

15311826613

Click to add WeChatThe metal ore of the ore of this project is rich in iron, phosphorus and other metals. The ore is composed of incompletely consolidated and loose igneous carbonate weathering residual mineral debris and supergenes The formed mayenite and earthy hematite clay are formed. The presence of a large amount of slime interferes with the separation and purification of minerals such as apatite and magnetite. The minerals are wrapped around each other and are closely connected, making it difficult to dissociate by grinding. ; Mineral isomorphism is serious, and the lattices of titanium, iron, manganese, aluminum, and magnesium replace each other, making the mineral composition very complex.

The raw phosphate ore is fed into the raw material warehouse by a loader. The warehouse is equipped with a belt feeder and a belt conveyor to transport the raw materials to a high-concentration mixing tank and add water to mix the slurry. . The uniformly stirred slurry is transported by the slurry pump to the raw ore desliming cyclone for desliming. The desludged mud is transported to the tailings sedimentation tank. The underflow of the cyclone flows to the ball mill for grinding. The overflow of the cyclone flows to the high-efficiency mixing tank, add chemicals into the stirring tank and stir evenly, then enter the flotation process.

The flotation process is a forward flotation process of one coarse, one sweep and two fines. The flotation concentrate is transported to the concentrate pump box by the foam pump, and then sent to the concentrate dehydration system for dehydration. The product is phosphate concentrate; the flotation tailings are transported to the tailings dehydration system by tailings pumps for dehydration. The dehydrated dry tailings are transported to the tailings storage by dump trucks for storage, and the dehydrated filtrate is returned to the production cycle for use.

This phosphate rock flotation project has a high rate of qualified products, low investment, short construction period and quick results for the entire mineral processing project. In addition, Xinhai implemented the principle of combining source control and tail treatment to reduce pollution.

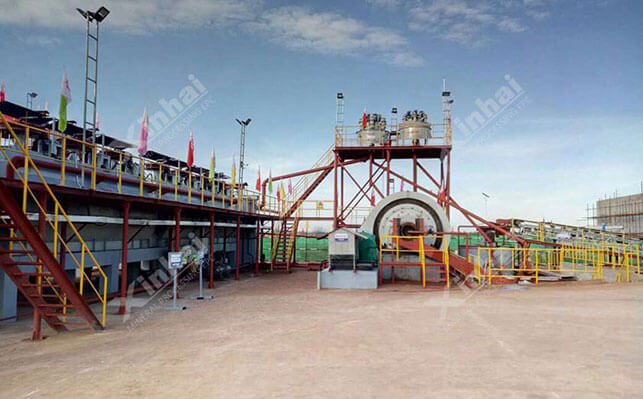

Uganda phosphate mine project grinding and grading site

Uganda phosphate rock project flotation site

Uganda Phosphate Mine Project Flotation Site