15311826613

Click to add WeChatDuring the working process of the mining flotation machine, daily operation is very important. It is one of the main factors affecting the flotation effect of the flotation machine. The operator of the processing plant should be based on the nature of the ore, processing capacity, product requirements and equipment requirements. Adjust the flotation machine appropriately according to wear and tear conditions, including the slurry level, aeration volume, circulation hole area and stirring mechanism clearance, etc.

Let's take a look at the main contents of the four major points of the flotation machine!

The level of the slurry level is usually controlled by the height of the tailings weir gate. If there is a medium ore box, its gate The size controls the liquid level in each tank. During the operation of the mining flotation machine, the operator can appropriately increase the gate size while ensuring the quality of the concentrate and tailings, thereby improving the processing capacity of the equipment.

It should be noted that when the gate is too large, the slurry level is low and the foam layer is thick. If the scraping depth is not well controlled,failure to scrape out the mineralized bubbles in time will cause loss of concentrate. On the contrary, when the slurry liquid level is too high, the foam layer is thin and the secondary enrichment effect is poor. Some unmineralized gangue particles are easy to enter the concentrate, affecting the final flotation effect.

Practice has shown that increasing the aeration volume within a certain range can greatly improve the production capacity of the mining flotation machine and improve Flotation index, and the size of the aeration is mainly determined by the type of flotation machine and the requirements of the flotation process. When the aeration amount is too large, the liquid surface will turn upside down and the foam layer will become unstable, which will affect the flotation effect. However, when the aeration is insufficient, some useful minerals cannot adhere to the bubbles and emerge in time, affecting the processing capacity of the mineral processing flotation machine and causing concentrate loss.

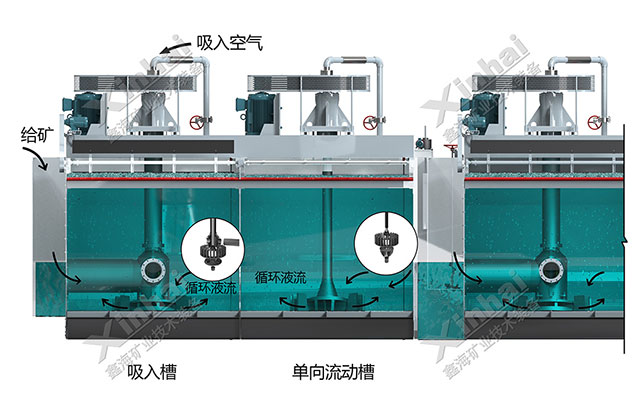

Usually, the inflation amount of the pressure-type flotation machine needs to be adjusted by the amount of air pressure; the air of the self-priming flotation machine generally passes through a sleeve or sleeve. The sleeve and the hollow shaft enter at the same time. At this time, the air intake volume affects the slurry feed volume. The operator should pay attention to adjusting the air intake volume and slurry feed volume (the air intake volume of the sleeve and hollow shaft is generally through the cover plate or end of the sleeve). board for adjustment). The air intake volume of the sleeve has a small impact on the slurry suction volume, while the air intake volume of the hollow shaft has a greater impact on the slurry suction volume. Therefore, it is necessary to consider the slurry suction volume while ensuring the inflation volume.

In the production process, the size of the circulation hole will directly affect the slurry circulation volume and air suction volume. Generally, increasing the circulation hole area can increase the chance of re-mineralization of the slurry, but at the same time, it will also increase the power consumption, the degree of wear and the crushing degree of the mineral particles. If it is too large, it may even cause the liquid surface to turn over.

At this time, the operator of the mining flotation machine should adjust the circulation hole area according to the product quality and the processing capacity of the flotation machine to ensure appropriate ( (smaller) circulation volume, for example, you can block part of the circulation holes, or block part of each circulation hole. At the same time, pay attention to regularly removing debris that is not artificially blocked on the circulation holes.

After long-term operation, the impeller of the flotation machine will cause a certain degree of wear of the stirring mechanism, resulting in the gap between the impeller and the stator. The gap is enlarged, while the air suction volume and slurry suction volume are reduced.

Generally, the operator of the mining flotation machine can adjust the axial gap between the impeller and the stator through the adjusting gasket between the bearing seat and the sleeve to keep it within the range of 6-10mm; The radial clearance is generally not modified because it is difficult to adjust. If the gap of the mixing mechanism is too large and cannot be adjusted, the operator should replace the impeller or stator in time.

Flotation is one of the common mineral processing processes in mineral processing plants. The flotation machine will directly affect the final technology during operation. The importance of indicators and economic indicators can be imagined. Therefore, flotation machine operators are required to pay attention to every detail in the flotation process and improve their daily operations, maintenance and overhaul skills to ensure the stable operation of the flotation machine.