Xinhai overflow ball mill has a simple production process, high grinding efficiency and long service life. It saves about 30% energy compared with other ball mills of the same specification. It has two types: energy-saving type and conventional type, which can be selected according to user needs.

【Processing Capacity】: 0.17~160t/h

[Feeding particle size]:≤25mm

[Discharge particle size]:≤0.2mm

【Application Environment】:It is suitable for grinding various metal and non-metallic ores. It is mostly used for fine grinding in two or more stages of grinding operation, so that qualified particle size can be obtained directly.

15311826613

Click to add WeChatExcept for the different production conditions and ore discharge method of the grid ball mill, the overflow ball mill can be configured according to the grid ball mill standards. In addition, the overflow ball mill also has the following features:

1. The engine uses large double-row spherical roller bearings instead of sliding bearings, which greatly reduces friction, makes it easy to start, and saves 20-30% of energy;

2. The grooved annular lining plate is used to increase the contact surface of the ball ore, strengthen the grinding effect, and have the ability to lift the ore, reducing energy consumption;

3. The bearing uses static and dynamic pressure Bearings, operation is smooth and reliable.

4. The overflow ball mill below 1.2m can be made into an integral frame design. The entire mill is installed on an integral welded frame. The frame is connected to the foundation for easy installation and debugging ( The same can be said for grid ball mills).

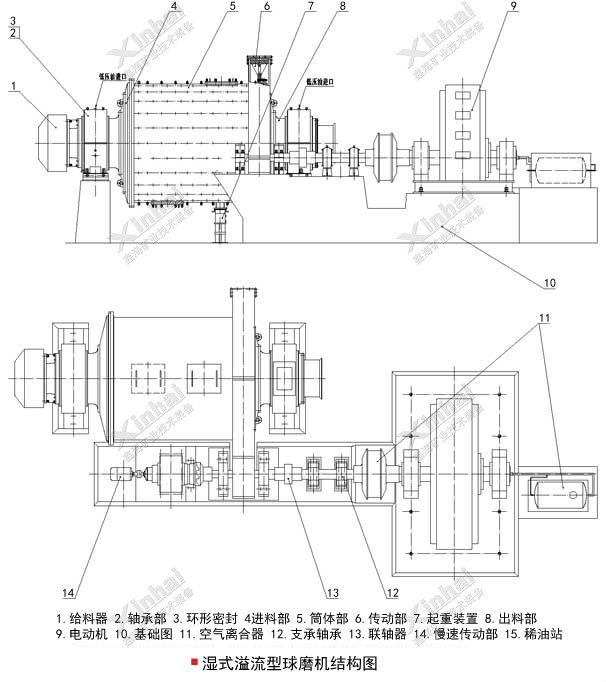

The structure of the ball mill is similar to that of the lattice type. It mainly includes inlet and outlet parts, main bearings, rotary part, transmission part, air clutch, main motor, slow speed transmission device, jacking device, lubrication system, electronic control system, etc.

The working principle of the overflow ball mill is mainly supported by rolling bearings. The cylinder is driven by the transmission device to rotate, so that the materials and steel balls rotate together with the cylinder, and complete the dropping, impact, impact and self-grinding operations in the cylinder to realize the material grinding. When the material is continuously fed, it will be under pressure, causing the material in the cylinder to gradually be discharged to the discharge end. When the slurry is higher than the lower edge of the hollow shaft at the discharge end, the material will flow overflowing by itself, and the steel at the discharge end will The balls and coarse materials will return to the mill through the anti-spiral blades and continue grinding.

An iron ore grid ball mill and classifier grinding site

Malaysian gold mine ball mill grinding site

Grid ball mill grinding site of a copper mine

| Model | Barrel diameter (mm) | Barrel length (mm) | motor Model | Motor power (kW) | length(mm) | Width (mm) | Height (mm) | Processing power (t/h) | Effective volume (m3) | Ball loading amount (t) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MQYg 0912 | 900 | 1200 | Y1800L-6 | 15 | 3666 | 1835 | 1400 | 0.25~1.2 | 0.7 | 1 | 4265 |

| MQYg 0918 | 900 | 1800 | Y225M-8 | 22 | 4401 | 2535 | 2070 | 0.25~1.6 | 0.9 | 1.66 | 5235 |

| MQYg 1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512 | 2076 | 1620 | 0.17 ~4.1 | 1.14 | 1.9 | 9610 |

| MQYg 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745 | 2352 | 1778 | 0.26~6.15 | 2.4 | 4.8 | 12219 |

| MQYg 1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2412 | 1728 | 0.34 ~8.3 | 3.7 | 7.8 | 15600 |

| MQYg 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4 ~4.5 | 2.2 | 4.2 | 17125 |

| MQYg 1530 | 1500 | 3000 | JR117-8 | 80 | 7253 | 3070 | 2280 | 2.8 ~9 | 5 | 10 | 21129 |

| MQYg 1536 | 1500 | 3600 | JR126-8 | 110 | 8595 | 3185 | 2280 | 2.8 ~10 | 5.4 | 10 | 23933 |

| MQYg 1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 | 27500 |

| MQYg 1557 | 1500 | 5700 | JR127-8 | 130 | 10880 | 3254 | 2370 | 4.5 ~16 | 8.9 | 15 | 29359 |

| MQYg 1836 | 1800 | 3620 | JR136-8 | 180 | 8865 | 3683 | 2785 | 4.5 ~29 | 8.2 | 13.8 | 34970 |

| MQYg 1845 | 1800 | 4520 | JR137-8 | 210 | 9750 | 3683 | 2785 | 5~33 | 10.2 | 19 | 37480 |

| MQYg 1857 | 1830 | 5720 | JR137-8 | 210 | 11009 | 3683 | 2785 | 6~40 | 12.5 | 22 | 42096 |

| MQYg 1863 | 1800 | 6320 | JR138-8 | 320 | 11690 | 3781 | 2775 | 6~45 | 14.2 | 25 | 45520.5 |

| MQYg 1870 | 1800 | 7020 | JR138-8 | 245 | 12599 | 3783 | 2735 | 7~47 | 15 | 31.5 | 45136 |

| MQYg 1875 | 1800 | 7500 | JR138-8 | 245 | 12850 | 3783 | 2775 | 7.5 ~54 | 17 | 30 | 49450 |

| MQYg 2122 | 2100 | 2200 | JR128-8 | 155 | 7235 | 4120 | 3083 | 5~29 | 6.6 | 20 | 35963 |

| MQYg 2130 | 2100 | 3000 | JR136-8 | 180 | 8220 | 4220 | 3083 | 6.5 ~36 | 9 | 27 | 40157 |

| MQYg 2136 | 2100 | 3600 | JR137-8 | 210 | 8958 | 4320 | 3025 | 7.5 ~42 | 10.8 | 23.5 | 44132.5 |

| MQYg 2145 | 2100 | 4500 | JR138-8 | 245 | 10350 | 4268 | 3121 | 10 ~45 | 13.5 | 23.6 | 42772 |

| MQYg 2430 | 2400 | 3000 | JR138-8 | 280 | 9023.5 | 4836.4 | 3490 | 7.2 ~92 | 11.5 | 22.5 | 57455.5 |

| MQYg 2436 | 2400 | 3600 | JR137-6 | 280 | 9623.5 | 4836.4 | 3490 | 8 ~110 | 13.8 | 25.5 | 60861.5 |

| MQYg 2442 | 2400 | 4200 | JR138-8 | 320 | 10204.5 | 4836.4 | 3440 | 8 ~130 | 16.5 | 31.5 | 63829.5 |

| MQYg 2445 | 2400 | 4500 | JR1510-8 | 380 | 11132.5 | 5091.4 | 4065 | 8.5~140 | 17.5 | 31 | 75923 |

| MQYg 2460 | 2400 | 6000 | JR1510-8 | 450 | 12623.5 | 5201.4 | 4060 | 9 ~180 | 23 | 40 | 83869 |

| MQYg 2727 | 2700 | 2700 | JR137-6 | 280 | 8901 | 4786.4 | 3620 | 7 ~110 | 13.8 | 29 | 66201 |

| MQYg 2730 | 2700 | 3000 | JR137-6 | 280 | 9201 | 4786.4 | 3620 | 8 ~115 | 15.3 | 32 | 72415 |

| MQYg 2732 | 2700 | 3200 | JR1410-8 | 320 | 10729 | 5000 | 3620 | 8 ~120 | 15.7 | 32 | 83110 |

| MQYg 2736 | 2700 | 3600 | JR158-8 | 380 | 10764 | 5150 | 3620 | 12~145 | 17.7 | 37 | 90441 |

| MQYg 2740 | 2700 | 4000 | JR1510-8 | 380 | 10870 | 5050 | 3620 | 12.5 ~152 | 19 | 40 | 93441 |

| MQYg 2745 | 2700 | 4500 | JR1510-8 | 380 | 11664 | 5150 | 3620 | 12.5 ~163 | 20.5 | 40 | 96196 |

| MQYg 2747 | 2700 | 4700 | JR1510-8 | 400 | 11864 | 5150 | 3620 | 13~170 | 23 | 45 | 97605 |

| MQYg 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12550 | 6750 | 5150 | 14~180 | 21.4 | 45 | 112430 |

| MQYg 3245 | 3200 | 4500 | TDMK630-36 | 630 | 13950 | 7200 | 5152.5 | 95~110 | 32.8 | 65 | 141629 |

| MQYg 3660 | 3600 | 6000 | TDMK1250-40 | 1250 | 19780 | 7700 | 5496 | 120~200 | 55 | 102 | 193483 |