15311826613

Click to add WeChatThe XJM-S flotation machine for silica is a type of mechanical agitation flotation machine. It can self-aspirate and does not require external air supply. It has good sorting effect, simple system, large processing capacity and small floor space. Low energy consumption, easy operation and maintenance. Let’s take a detailed look at the working principle and structural characteristics of the XJM-S flotation machine for silica!

The working principle of this flotation machine is to use a double-layer umbrella The shaped impeller stirs quickly, inhaling the slurry, chemicals and sufficient air, forming a strong three-phase turbulent flow field in the impeller cavity, between the impeller and the stator and around the stator. The bubbles generated after inflating are cut into pieces suitable for mineral particle flotation. size, evenly distributed in the slurry, providing a platform for slime flotation. The working process is as follows:

1. Under the action of the impeller rotation of the silica flotation machine, the slurry is sucked into the lower impeller from the false bottom. In the cavity, air and chemicals are sucked into the upper layer of the impeller along the air guide sleeve, so that the three phases of solid, liquid and gas are thrown into the flotation tank at high speed along the outer edge of the impeller through the stator and flow stabilizing plate, and a jet effect occurs at the outlet of the impeller. Eddy currents and vacuum zones are formed.

2. Under the action of strong turbulence and micro-jet flow of the slurry, it is dispersed into fine bubbles and evenly distributed in the tank. The slurry in the lower tank is in a fully turbulent state. The turbulent flow causes particle migration, thereby keeping the particles levitate.

3. The stress exerted by the flow on the fluid and solid particles causes mutual condensation, air dispersion and particle- Bubbles collide with each other. After the hydrophobic mineral particles collide with the bubbles, adhesion occurs when the water film at the contact point ruptures (that is, the bubbles are mineralized). The bubbles float to the surface of the slurry and gather into a foam layer, which is scraped out of the tank to form a fine layer. Mineral products; the unfloated ore particles that cannot float will enter the subsequent sorting chamber with the middle ore, and the above sorting process will be repeated; the hydrophilic mineral particles cannot adhere to the air bubbles after collision and remain in the slurry, and will eventually be collected from the tailings box discharge.

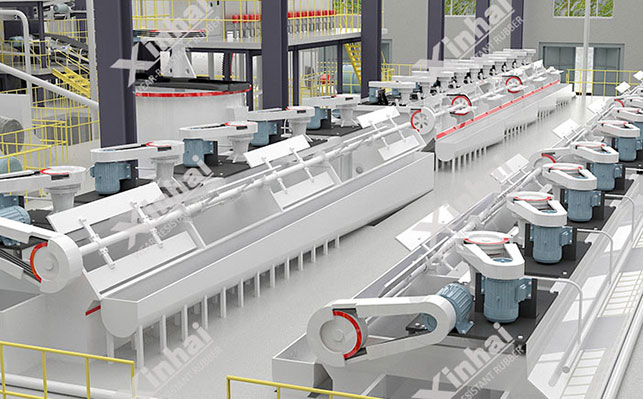

XJM-S flotation machine for silica is generally composed of multiple chambers (2 to 5 chambers). Each chamber can be arranged horizontally or Ladder layout. Flotation process can also realize the secondary flotation process (the final concentrate is the concentrate of the primary flotation concentrate and flotation again).

Ladder layout flotation machine: front flotation chamber (1, 2, 3) and rear flotation chamber (5, 6 ) Use the secondary flotation switching box (4) to realize the conversion between primary flotation and secondary flotation processes, in which the front flotation chamber and the rear flotation chamber can be composed of single chamber or multiple chambers.

Each chamber of the flotation machine is a flotation system. The slurry flows from the first chamber through each chamber and is sorted chamber by chamber. The concentrate is scraped out by the scraper mechanism, and the tailings are passed through multiple The flotation slurry is discharged from the tailings box.

This article mainly introduces the characteristics, working principle and composition characteristics of the XJM-S flotation machine for silica. I believe everyone also has a certain understanding of this flotation machine.