15311826613

Click to add WeChatQuartz sand is an important raw material in the glass industry, but with the development of technology, the application field of quartz sand has been further broadened, especially in the high-tech field. The higher the purity of quartz sand, the higher the application field. In order to improve the utilization rate of quartz sand, for quartz sand with high mud content and fine particles, ore washing should be carried out first to remove mud and impurities in advance, so as to provide qualified products for subsequent ore dressing and purification. So, what are the common quartz sand scrubbing equipment in ore dressing plants? Let's get to know them together!

The equipment commonly used in quartz sand washing operations mainly includes spiral sand washing machine, wheel sand washing machine, vibration sand washing machine, drum sand washing machine and hydrocyclone, etc.

Spiral sand washing machine is mainly used to remove light impurities and soil in quartz sand. It has a compact structure and is easy to operate and maintain.

During operation, the material is washed under the action of water by the rotating motion of the spiral blade. When the material enters the spiral sand washing machine through the feeding device, the material is mixed with water under the push of the spiral blade to form a material-water mixture. Under the rotation of the spiral blade, the material continues to move forward in the tank, and light impurities and fine particles are discharged with the water flow.

Wheel sand washing machine is also often called bucket sand washing machine or turbine sand washing machine. It is a common water washing equipment, mainly used to wash impurities and fine powder from materials such as quartz sand, river sand, and machine-made sand to improve the quality of sand. The wheel sand washer achieves material cleaning and dehydration through the rotation of the wheel bucket. It has a compact structure, small footprint and high water resource utilization. In the quartz sand washing operation, it is mostly suitable for washing and dehydrating fine-particle ores, which can not only ensure the cleanliness of sand and gravel, but also effectively maintain the sand quality.

During operation, the material enters the spiral sand washing machine through the feeding device, and is mixed with water under the push of the spiral blade to form a material-water mixture. Under the rotation of the spiral blade, the material continues to move forward in the tank, and light impurities and fine particles are discharged with the water flow. The cleaned material is gradually dehydrated under the lifting action of the spiral and finally discharged out of the machine.

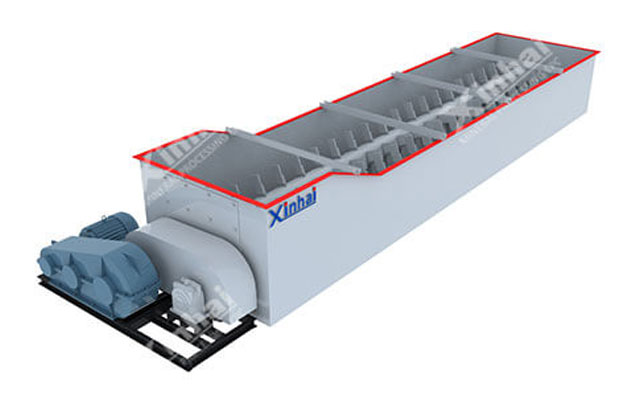

The drum ore washing machine, also known as the drum sand washing machine or the cylindrical ore washing machine, is a device used for mineral cleaning and grading. It can perform continuous cleaning operations, has high production efficiency, and has a simple structure, which is easy to operate and maintain. It can be suitable for the cleaning of minerals and sand and gravel of various hardness and humidity.

During operation, the material enters the rotating drum through the feeding device. As the material tumbles continuously in the drum, it is fully mixed with the water material. During the rotation process, materials of different particle sizes and densities are graded according to their physical properties. The cleaned material moves upward with the rotation of the drum and is discharged through the screen. At the same time, dehydration is achieved, and impurities and soil are separated during the cleaning process and discharged through one end of the drum.

The vibrating sand washing machine uses high-frequency vibration to separate the adhesion and impurities between the materials to achieve the purpose of cleaning. It is characterized by simple operation, convenient maintenance, high degree of automation, high sand washing efficiency, large processing capacity, and low energy consumption. It is suitable for processing quartz sand of various particle sizes, especially good at processing materials with high mud content and requiring efficient washing. In addition to the cleaning function, the vibrating sand washing machine can also effectively remove moisture from the material.

During operation, the material enters the screen surface of the vibrating sand washing machine evenly through the feeding device. The vibration generated by the vibration motor makes the material roll on the screen and mix with water to achieve cleaning. Under the action of vibration, materials of different particle sizes are layered according to particle size. Fine materials are discharged through the screen, and coarse materials are on the upper layer. Through the vibration of the screen, the moisture in the material is thrown out to achieve dehydration.

Hydraulic cyclone is a device that uses centrifugal force to classify, concentrate and dehydrate materials. Especially in the washing and dehydration operation, it can effectively improve efficiency and reduce the loss of fine particles. The cyclone is small in size, occupies less space, and is easy to install and maintain.

During operation, the material is mixed with water to form a slurry, which enters the cyclone through the feed port. The slurry rotates inside the cyclone due to the acceleration of the nozzle. The centrifugal force generated by the rotation causes the heavy material to move to the outer wall and be discharged through the bottom, while the light material (or fine-grained material) remains in the center, forming an overflow and is discharged from the top to achieve dehydration and purification.

The above is an introduction to the types and characteristics of equipment commonly used for quartz sand washing. In actual ore dressing plants, how to choose quartz sand washing equipment depends on the requirements for quartz sand purification and ore dressing process. Therefore, it is recommended to conduct ore dressing tests, design a reasonable quartz sand ore dressing process through test analysis, and give suitable quartz sand ore dressing and washing equipment types and models.