15311826613

Click to add WeChatAs a hard currency, gold is deeply loved by people. Nowadays, most people start to invest in gold, whether it is gold bars or gold jewelry. The ores for obtaining gold include placer gold, single gold deposits and some polymetallic gold mines rich in other metal minerals, such as copper-containing gold ores. So how to effectively select gold from copper-containing gold ores? Let's take a copper-containing gold mine as an example to introduce its gold selection process.

The original ore is a fissure-filled replacement gold-bearing polymetallic sulfide ore dominated by medium-temperature hydrothermal fluids. The main metal minerals are native gold, silver-gold, galena, pyrite, chalcopyrite, etc. The secondary metal minerals are hematite, limonite, cerussite, lead iron alum, copper blue, bornite, pyrrhotite, wolframite, scheelite, etc. Most of these metal minerals are distributed around the primary minerals in an alternating pattern at the edges. Gangue minerals are mainly quartz, plagioclase, sericite, calcite, followed by amphibole, chlorite, etc.

The gold in the minerals is mainly silver-bearing natural gold, with a coarse particle size (+0.074mm accounts for more than 60%), and is not closely related to other metal minerals. Minerals other than natural gold are closely interwoven, with extremely uneven particle sizes, difficult to separate, and are difficult to select ores.

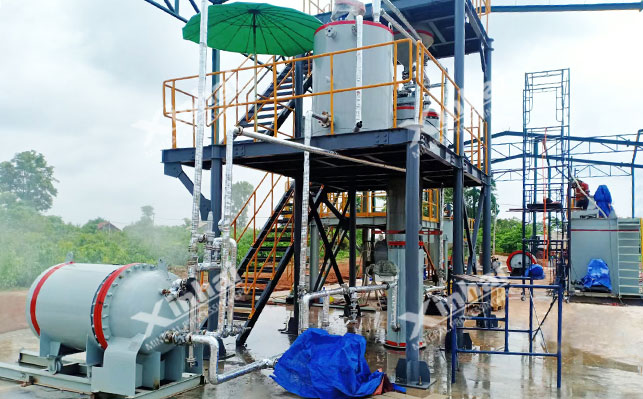

Through the analysis of the beneficiation test of the copper-bearing gold ore, the grinding-cyanidation-leaching gold extraction process was finally designed for it.

The copper-bearing gold ore adopts a two-stage closed-circuit grinding process, the main purpose of which is to achieve monomer dissociation between minerals, which is convenient for subsequent gold cyanidation operations. After grinding and classification, the ore fineness is -0.038mm95%.

Under the premise that the grinding fineness is -0.038mm, accounting for 96%, a certain amount of sodium hydroxide is added for leaching. The leaching time is 24 hours, and then ZJ02 leaching agent (a mixture of two inorganic salts containing ammonium) is added under the condition of adding kerosene 30g/t.

Ammonium can cooperate with copper, and Cu(CN)2- in the ore pulp can react with NH3 to form copper-ammonia complex ions, eliminating the competition between copper and CN-, which is conducive to the dissolution of gold and the elimination of the influence of copper. In addition, ZJ02 contains mercury salts that can precipitate mercury into cyanide insoluble mercury, liberate CN, and eliminate the consumption of mercury on cyanide.

This gold extraction process eliminates the influence of copper and mercury on leaching, and the comprehensive use of other strengthening measures greatly strengthens the leaching operation and improves the leaching effect. At the same time, due to the reaction between copper and NH3, mercury is precipitated, eliminating their influence on the replacement, and the replacement operation recovery rate is raised to more than 99.5%. The lean solution containing copper up to 5000mg/L3 can also be returned for use without affecting leaching and replacement.

The above is an introduction to the process scheme for gold selection in a copper-containing polymetallic gold mine. According to the different properties of gold ore, the ore selection methods are also different. Common gold selection methods include flotation, gravity separation, cyanidation and many other methods. How to choose, it is recommended to conduct ore selection test analysis first, and design a suitable gold extraction process flow through analysis, which has obtained a good return on investment.