15311826613

Click to add WeChatLepidolite ore is one of the main resources for obtaining lithium. It is a mineral produced from pegmatite-type lithium deposits. This type of mineral has complex properties and is not easy to react with acid and alkali at room temperature. It is difficult to beneficiated. At present,the common lepidolite beneficiation methods for extracting lithium include flotation, acid, alkali and salt methods. Let’s find out together below.

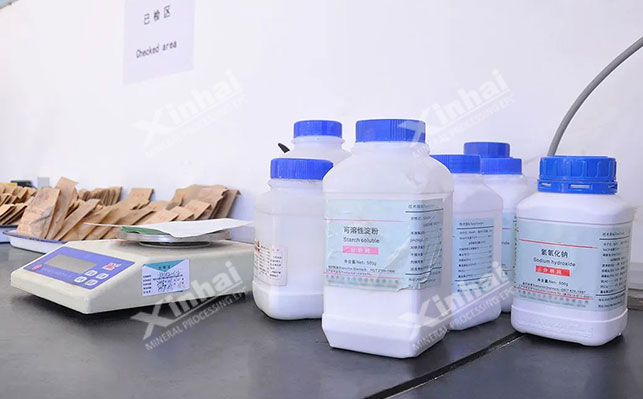

Since lepidolite ores are mostly fine-grained in nature, they are often symbiotically embedded with quartz, feldspar and other gangue minerals. For this type of lepidolite, flotation method is often used to complete the lithium selection operation. In the flotation process, the chemical system is very important. Under acidic conditions, amine collectors are used to float lepidolite; under alkaline conditions, fatty acid collectors or combined collectors are used to complete the flotation of lepidolite. Operation.

Note that the combination of anion and cation collectors will use the synergy between agents to increase the recovery rate of lepidolite concentrate.

The acid selection of lepidolite is very common. The main principle is to use hydrogen ions from solution to lepidolite. Diffusion of orthosilicate film layer causes lepidolite to decompose into soluble sulfate, which is then divided into acidification roasting and concentrated sulfuric acid at room temperature according to different treatment methods. Several methods of pretreatmentandmixed acid treatment.

In addition, according to different calculations, it can also be divided into sulfuric acid method and hydrofluoric acid method. The sulfuric acid method is to acidify and roast lepidolite and concentrated sulfuric acid at a suitable temperature to obtain acidified clinker. Perform water leaching to obtain a lithium sulfate solution, and the associated valuable metals rubidium and cesium after acidification treatment become soluble salts. The treatment process using hydrofluoric acid is similar to that of sulfuric acid. The leaching temperature is lower, the leaching time is shorter, and the energy consumption is lower, which provides favorable conditions for subsequent impurity removal. On this basis, using a mixed acid of hydrofluoric acid and sulfuric acid for leaching can achieve a higher leaching rate while reducing acid consumption.

The alkali selection of lepidolite is to roast lepidolite with lime, and use alkali to dissolve SiO2 in the solution. In alkali or gypsum, the silicate is converted into soluble lithium aluminate by heating, thereby reacting the mineral with a mixture of limestone or hydroxide to obtain lithium hydroxide or lithium carbonate.

Sulfate is commonly used for spodumene selection by salt method. In the roasting process, when lepidolite is calcined at high temperature, the structure becomes loose and an ion exchange reaction occurs. That is, the metal ions in the added material occupy the structural position of the original lithium ion, causing it to break away from the insoluble aluminum silicate to form soluble sulfate. Methods.

The above four methods are common methods for lepidolite beneficiation to extract lithium. In the actual mineral processing plant, the specific process plan to be selected depends on Ore beneficiation test analysis report is designed. If copied and applied, it is likely to exceed the budget, or the technical modifications in the later stage will outweigh the gains. It is better to conduct a beneficiation test in advance and design a suitable lepidolite beneficiation process plan according to the actual situation. The desired return on investment has been achieved.