15311826613

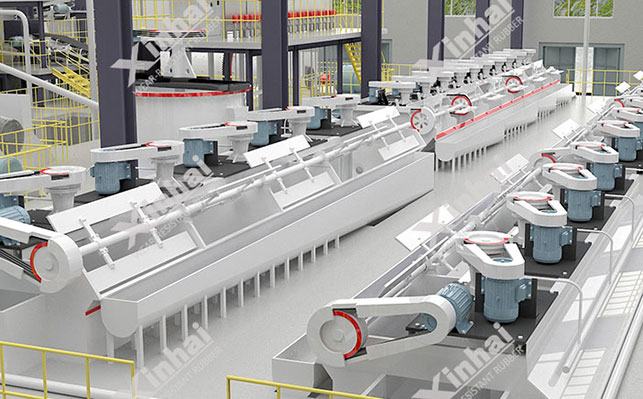

Click to add WeChatSmall flotation machine is one of the commonly used separation equipment in small and medium-sized mineral processing plants. Its application range is suitable for many types of minerals. When gravity separation and magnetic separation cannot obtain high-grade minerals, flotation machine can also be used. flotation. So how to select a small flotation machine in a mineral processing plant? At present, what are the problems when selecting a small flotation machine? Let’s answer these two questions below!

As for how to select a flotation machine, this needs to be based on mineral processing tests. To make the selection, because it is necessary to determine the nature of the ore and the actual needs of the concentrator for selection. You cannot just imitate other people's selection based on a certain scale and similar ores. This is not scientific and rigorous, so it is still recommended to conduct mineral processing tests and make selections based on the results. This article only introduces the flotation machine selection process (program).

Generally, the selection of small flotation machines can be divided into three steps:

1. Select representative minerals to conduct small tests to determine the basic mineral processing conditions;

2. Conduct an expanded continuous selection test to optimize the selection process conditions;

3. Determine the volume and quantity of industrial flotation machines based on the empirical amplification factor of flotation time.

Conventional small mineral processing plants will select flotation machines through mineral processing tests, but only Focus on two factors: first, focus on the properties of the ore, such as mineral composition, mineral particle size distribution, shape and mineral floatability; second, focus on the flotation environment, such as the dosage of chemicals, pH value, flotation time, slurry concentration and temperature, etc. Therefore, for the selection of flotation machine, these aspects are not perfect, and there is a lack of testing on flotation machine stirring speed, aeration rate and industrial matching degree.

1. High or low stirring speed will cause chaos in the slurry, which is detrimental to coarse particle flotation

The stable flow of the flotation machine (impeller stirring Reynolds number) has a dual effect on flotation. When the turbulence intensity is low, it is beneficial to the stability of the foam, and the mineral particles are not easy to fall off from the bubbles. However, if it is too low, it will be detrimental to the separation between the mineral particles and the bubbles. Collision adhesion and mineral particle suspension occur.

When the turbulence intensity is high, it is conducive to the collision and adhesion of mineral particles and bubbles and the suspension of mineral particles. If it is too high, it is easy to cause the mineral particles to detach from the bubbles.

2. The aeration speed directly affects the flotation performance

Although aeration is simple, it is one of the most important chemicals in flotation operations. The size will affect the separation performance of the flotation machine. If an externally aerated mechanical stirring flotation machine is used, the amount of aeration of the minerals to be selected cannot be determined, which may cause the supporting fan to be too large and increase the energy consumption of the processing plant; if the fan is selected If the size is too small, the aeration volume cannot be reached, the flotation effect cannot be fully exerted, and the flotation process will become difficult to operate.

The above are the selection requirements for small flotation machines and some shortcomings in the selection. Therefore, in order to improve flotation In order to determine the flotation index of the flotation machine, not only the mineral processing test must be carried out, but also the test must be comprehensive to ensure the working efficiency of the flotation machine. Improve the comprehensive income of the mineral processing plant.