15311826613

Click to add WeChatQuartz sand is one of the important industrial raw materials and can be widely used in glass, ceramics, casting, metallurgy, ferrosilicon smelting and other industries. However, quartz sand often contains impurity minerals such as iron, phosphorus, calcium, mica, etc., and these impurities are the key to its process application. Therefore, obtaining high-purity quartz sand is a major consideration in the mineral processing industry. So common high-purity quartz sand What is the production process of pure quartz sand? The production process can generally be divided into two types: pretreatment process and selection process. Let’s follow the editor to find out more!

The pretreatment production process flow of silica can include: Crushing and screening, Grinding two parts.

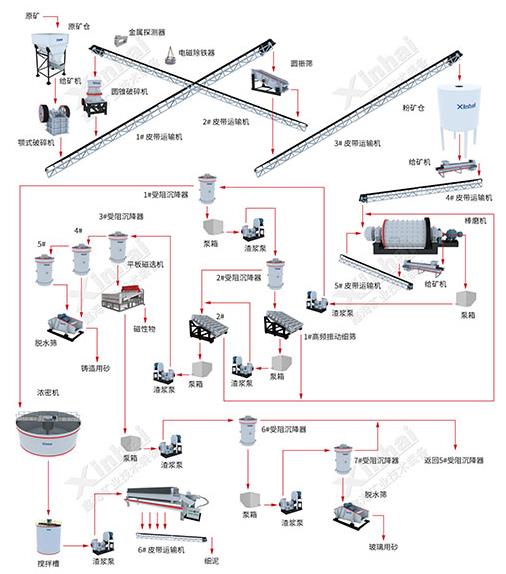

This process mainly uses crushing and screening equipment to crush quartz sand raw ore into small-grained minerals in order to provide for the separation production line Qualified materials. The production process is as follows: the raw ore enters the jaw crusher for crushing through the vibrating feeder, and the crushed products are sent to the circular vibrating screen by the belt conveyor for screening. The qualified materials under the screen are sent to the next stage, and the unqualified materials on the screen are sent to the next stage. The material is sent by another belt conveyor to the spring cone crusher for secondary crushing and screening operations. In this step, before entering the crusher, the silica will undergo metal detection and iron removal, and then be sent to crushing and classification, forming a closed loop to improve crushing and screening efficiency. .

The crushed silica needs to be further ground to separate the silica and impurities as much as possible to achieve the optional particle size. The specific process is: after crushing, the materials are sent to the powder silo by the belt feeder for storage, and then sent to the rod mill for grinding by the feeder. Qualified materials are sent to the blocked settler by the slurry pump for the next step of processing.

The silica selection process takes iron-containing silica as an example. The commonly used process is magnetic separation. The specific process is as follows:

p>

After grinding and processing in the first blocked settler, the coarse concentrate is pumped into the second blocked settler for secondary settlement. , the settled qualified part enters the vibrating screen for processing. The slurry left by the screening will flow into the slurry pump and be sent to the third-stage sedimentation treatment. The qualified concentrate obtained will be dehydrated through the dewatering screen to obtain foundry sand.

Glass sand has higher requirements for the purity of silica, so its selection process will be better than that of foundry sand. More complicated, as mentioned above, a three-stage settlement process is used when producing foundry sand. The lower part of the first settlement process among the three settlements is used to produce glass sand. The specific process is as follows: the settled part of the slurry flows into the flat plate magnetic separator for separation operation to remove weak magnetic impurities. The product after impurity removal needs to be settled twice, and the settled concentrate flows into the dehydration screen. Carry out dehydration treatment to obtain qualified sand silica concentrate for glass.

After grinding and settling, the impurity minerals are directly sent to the concentrator for concentration and dehydration. The dehydrated product is passed through the stirring tank Stir, pump into the filter press and dehydrate again to reduce the water content to less than 20%, and use a belt conveyor to send it to the tailings reservoir for storage.

The above is an introduction to the process flow of quartz sand production. Depending on the environment in which quartz sand is used, the production processes selected are also different. No matter what kind of The processes are mainly focused on improving the purity of quartz sand. The higher the purity, the higher the price of quartz sand, and the industries it is used in are also high-end. According to different industry applications, Xinhai Mining can carry out quartz sand production process design and mineral processing plant construction design, etc. Welcome to consult Xinhai Mining!