The slurry suction or air suction can be set according to the needs, mechanical stirring, smooth operation and low failure rate.

【Processing Capacity】:0.06~24m3/min

【Effective volume】:0.15~24m3

【Application Environment】:BF flotation machine is mostly suitable for coarse particle flotation. The range of materials it handles is 0.074mm, accounting for 45%-98%, and the slurry concentration is<45%. Therefore, it has high separation efficiency and strong adaptability. It can be used in various metals and non-metallic materials. It is used in metal (non-coal metal) mineral processing plants.

15311826613

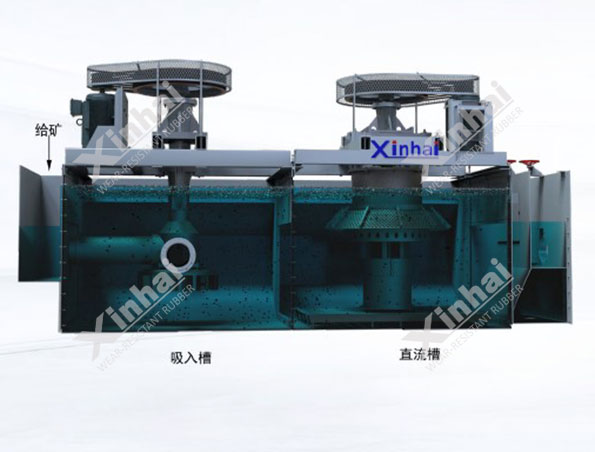

Click to add WeChatThe bf flotation machine produced by Xinhai Mining has both slurry suction and air suction functions, and is type I and type II. Type I is an improved design based on the SF type flotation machine and is a suction tank; Type II is an improved design based on the JJF type flotation machine and is a direct flow cell. Type I and Type II are used together to realize that each tank has the triple functions of air suction, slurry suction and flotation, forming a self-contained flotation circuit without any auxiliary equipment. The horizontal configuration facilitates process changes.

The cover plate of the Bf flotation machine and the impeller form an organic whole. When the impeller rotates, a vacuum is generated in the impeller cavity, which inhales enough air to feed ore and medium ore. The air suction volume is large (BF self-inhalation volume can reach 1.2m³ /(㎡·min));

The most important thing for coarse particle flotation is the flotation machine impeller structure, stator form and flotation tank form, and the impeller structure determines the slurry circulation capacity, air The suction amount and dispersion capacity also determine the mixing intensity of the slurry, so the impeller design of the coarse flotation machine is very critical;

The impeller and cover plate of the Xinhai BF flotation machine have reasonable and reasonable structures Relevant parameters reach optimal values, and at the same time, the cover plate converts the tangential rotation generated by the impeller into a radial slurry flow, preventing the slurry from swirling in the flotation tank and promoting the stability of the slurry liquid level.

The forward-inclined tank body has small dead spots and fast foam movement.

The impeller of the BF type flotation machine adopts a double conical disc backward-inclined closed impeller, which has strong slurry suction ability and can produce strong downward circulation, so it is beneficial to the flotation of coarse particles.

The flotation machine is equipped with automatic slurry level control, electric control and manual control devices, which can be selected according to customer needs or requirements.

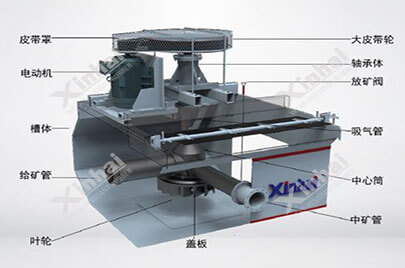

The structure of Bf type flotation machine mainly consists of belt cover, large pulley, motor, bearing, ore discharge valve, tank body, suction pipe, ore feeding pipe, center cylinder, and medium ore pipe , impeller, cover and other parts.

The working principle of the Bf type mechanical agitation flotation machine is that when the impeller rotates, the slurry in the upper and lower impeller cavities generates centrifugal force under the action of the upper and lower blades and is thrown around (Figure 1), forming a negative pressure zone in the upper and lower impeller cavities. . The slurry under the impeller is sucked in through the center hole of the lower conical disc of the impeller, mixed with air in the impeller cavity, and then thrown out to the surroundings through the channel between the cover plate and the impeller. After leaving the cover plate channel, the air and part of the slurry are directed toward The upper part of the flotation tank moves to participate in the flotation process. The other part of the slurry moves to the bottom of the flotation tank and is sucked by the impeller and enters the impeller cavity again, forming a downward circulation of the slurry. The existence of circulation under the slurry is beneficial to the suspension of coarse-grained minerals and can minimize the deposition of coarse sand in the lower part of the flotation tank.

Xinhai Bf flotation machine packaging and delivery site

Xinhai bf flotation machine on-site installation and commissioning of a copper mine project

Flotation site of a project of Xinhai bf flotation machine

| Model | Effective volume (m3) | Length×width×height (mm) | Impeller diameter (mm) | Impeller circumferential speed (m/s) | Air intake volume (m3/m2-min) | electric motorModel | Motor power (kW) | Processing power (m3/min) | Single tank weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| BF-0.15 | 0.15 | 550×550×600 | 200 | 6 | 0.9~1.05 | Y112M-6 | 2.2 | 0.06~0.16 | 270 |

| BF-0.25 | 0.25 | 650×600×700 | 250 | 6 | 0.9~1.05 | Y100L-6 | 1.5 | 0.12~0.28 | 370 |

| BF-0.37 | 0.37 | 740×740×750 | 286 | 7.2 | 0.9~1.05 | Y90L-4 | 1.5 | 0.2~0.4 | 470 |

| BF-0.65 | 0.65 | 850×950×900 | 300 | 7.35 | 0.9~1.10 | Y132S-6 | 3 | 0.3~0.7 | 932 |

| BF-1.2 | 1.2 | 1050×1150×1100 | 450 | 7.02 | 0.9~1.10 | Y132M2-6 | 5.5 | 0.6~1.2 | 1370 |

| BF-1.2 | 1.2 | 1050×1150×1100 | 450 | 7.02 | 0.9~1.10 | Y132M1-6 | 4 | 0.6~1.2 | 1370 |

| BF-2.0 | 2 | 1400×1450×1120 | 500 | 7.5 | 0.9~1.10 | Y160M-6 | 7.5 | 1.0~2.0 | 1750 |

| BF-2.8 | 2.8 | 1650×1650×1150 | 550 | 8.06 | 0.9~1.10 | Y180L-8 | 11 | 1.4~3.0 | 2130 |

| BF-4.0 | 4 | 1900×2000×1200 | 650 | 8 | 0.9~1.10 | Y200L-8 | 15 | 2.4 ~4.0 | 2585 |

| BF-6.0 | 6 | 2200×2350×1300 | 700 | 7.5 | 0.9~1.10 | Y225S-8 | 18.5 | 3.0~6.0 | 3300 |

| BF-8.0 | 8 | 2250×2850×1400 | 760 | 7.5 | 0.9~1.10 | Y225M-8 | 22 | 4.0~8.0 | 4130 |

| BF-10 | 10 | 2250×2850×1700 | 760 | 7.52 | 0.9~1.10 | Y225M-8 | 22 | 5.0 ~10 | 4500 |

| BF-16 | 16 | 2850×3800×1700 | 850 | 8.7 | 0.9~1.10 | Y280S-8 | 37 | 8.0 ~16 | 8320 |

| BF-16 | 16 | 2850×3800×1700 | 850 | 8.7 | 0.9~1.10 | Y280M-8 | 37 | 8.0 ~16 | 8320 |

| BF-20 | 20 | 2850×3800×2000 | 850 | 8.7 | 0.9~1.10 | Y280S-8 | 45 | 10.0 ~20 | 8670 |

| BF-24 | 24 | 3150×4150×2000 | 920 | 8.7 | 0.9~1.10 | Y315S-8 | 55 | 12.0 ~24 | 8970 |