High-concentration underflow forced discharge of ore can be realized according to user needs, meeting the requirements for dry discharge of concentrates and tailings.

[Processing Capacity]:20~3500㎡

< p>[Model specifications]: ZQN16~2000 (see parameter list for details)

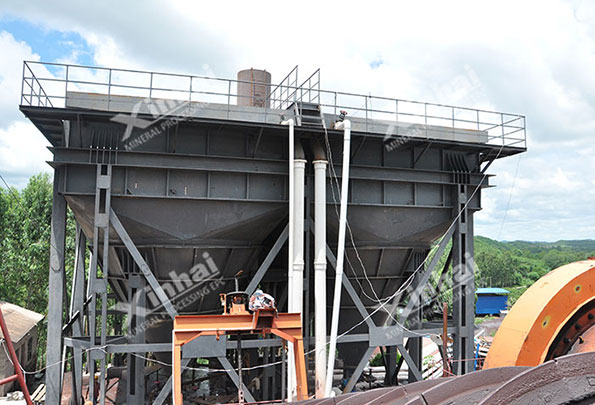

[Application Environment]:Multi-purpose It is used for clarification and concentration of flotation tailings. In addition, it can also be used for concentration and water return, classification and desliming, slurry pretreatment and other dehydration operations containing solid particles.

15311826613

Click to add WeChatThe inclined plate concentrator produced by Xinhai Mining Equipment is equipped with a stirring device in the center of the casing. The outer wall of the cone bucket is also equipped with a vibrator, which can effectively speed up the concentration of flocs and at the same time effectively prevent Slurry clogging.

Each sedimentation channel of the concentrator has the same feeding, graded concentration, sand discharge and overflow functions, and the same structural size, ensuring the stability and consistency of the operation of each graded concentration channel;

The same inclined plate group modules are combined and integrated to form the required total settlement area of the equipment, which can easily realize the large-scale equipment;

According to the different properties of the slurry and the different classification particle sizes, Carry out deformation design of the inclined plate channel to enable the equipment to achieve ideal performance;

The inclined plate group module uses intermittent high-frequency micro-vibration, and the inclined plate group module is automatically cleaned regularly to keep the materials on the inclined plate in order. Slide down to ensure that there is no accumulation of materials on the inclined plate and no blockage between the plates, thereby ensuring long-term and stable working performance of the equipment;

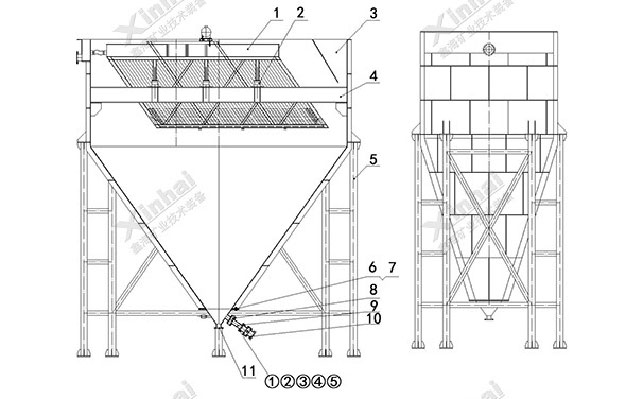

A special material removal device is set up in the thickening cone hopper to prevent the material from being thickened Accumulation in the cone.

The complete concentrator includes an upper box and a lower cone.

The concentration process of the inclined plate concentrator is completed in each independent inclined plate channel. The fine overflow or clean water is directly discharged from the overflow surface of each channel laterally, shortening the overflow discharge path and effectively solving the problem of the overflow discharge process. The problem of fine particle short circuit and circulation ensures that the equipment can achieve higher graded concentration efficiency, and the graded concentration return water efficiency can generally reach more than 70%.

| Model | 沉降面积(m2) | 锥斗数 | 长(mm) | 宽(mm) | 高(mm) |

|---|---|---|---|---|---|

| ZQN16 | 16 | 1 | 3690 | 1100 | 4360 |

| ZQN31 | 31 | 1 | 3760 | 2460 | 4360 |

| ZQN50 | 50 | 1 | 3690 | 3300 | 5260 |

| ZQN63 | 63 | 1 | 5560 | 2460 | 5630 |

| ZQN100 | 100 | 1 | 5560 | 3560 | 5500 |

| ZQN125 | 125 | 1 | 5510 | 4400 | 5660 |

| ZQN150 | 150 | 1 | 7710 | 3760 | 7890 |

| ZQN200 | 200 | 1 | 7710 | 4880 | 8160 |

| ZQN250 | 250 | 1 | 7710 | 6000 | 8500 |

| ZQN300 | 300 | 1 | 8000 | 7020 | 7890 |

| ZQN400 | 400 | 1 | 7710 | 9260 | 7890 |

| ZQN500 | 500 | 1 | 7710 | 11500 | 8500 |

| ZQN600 | 600 | 1 | 14880 | 7020 | 7890 |

| ZQN800 | 800 | 1 | 14880 | 9260 | 8160 |

| ZQN1000 | 1000 | 1、2、4 | 14880 | 11460 | 8500 |

| ZQN2000 | 2000 | 4、8 | 14880 | 22920 | 8500 |