15311826613

Click to add WeChatThe XJM flotation machine is a self-priming mechanical agitation flotation machine. The equipment is reliable in operation, easy to operate and control, has low labor intensity for workers, and requires less investment. In addition, the impeller and stator of the XJM flotation machine are made of wear-resistant materials and have a long service life.

[Processing capacity]:0.6~1.2m3/min (designed according to demand)

[Effective volume]:4~12m< sup>3 (customized according to needs)

[Application environment]:Mostly used for sorting iron ore, phosphorus hydrochloric acid, lead , zinc ore and slime below 0.5mm.

The up and down circulation volume of the impeller of Xjm flotation machine can be adjusted by itself. Through the adjustment device on the stator cover, the revised version The cross section where the circulation flows to adjust the amount of upper circulation;

The Xjm flotation machine adopts false bottom suction and peripheral series inflow to ensure that the slurry reaches a reasonable flotation state in the flotation tank;

p>

The stator of the Xjm flotation machine adopts a split design, which can ensure the suction of sufficient slurry;

Each classification tank of the According to the characteristics of the feed materials, different dosing mechanisms are implemented to improve the flotation effect.

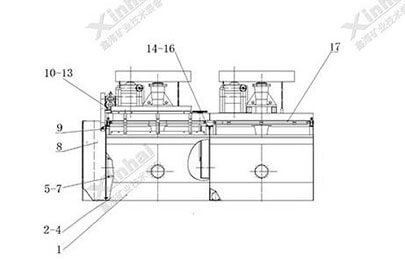

The XJM flotation machine consists of one or more flotation chambers , electric motor, inflatable mixer, foam scraper, slurry level adjustment mechanism, ore discharging mechanism and other parts.

The working principle of Xjm flotation machine is that when the impeller rotates, a negative pressure zone is formed in the impeller cavity, causing the The slurry is sucked into the impeller cavity, and at the same time, air is supplied from the air guide tube to mix the slurry with the air and chemicals. Under the action of the impeller, the air is evenly distributed in the tank body, and the useful minerals adhere to the bubbles and float upward. It enters the separation zone and is enriched to form a foam layer, which is scraped out by a scraper. The flotation particles in the tank that are not mineralized in time will enter the next flotation chamber to complete the flotation enrichment operation in sequence.

| Technical characteristics | Model number | ||||||||

| XJM-KS4 | XJM-KS6 | XJM-KS8 | XJM-KS12 | XJM-KS14 | XJM-KS16 | XJM-KS20 | |||

| Single slot Rongzhi (m3) | 4 | 6 | 8 | 12 | 14 | 16 | 20 | ||

| Unit processing capacity (t/m3·h) | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 | ||

| Unit mine pump processing capacity (m3/m3·h) | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | ||

| Material pressure (MPa) | < td colspan="7">0.04~0.12 (XJM-KS4 series)|||||||||

| Inflation rate (m3/m< sup>3·min) | 0.6-1.2 | ||||||||

| Power of stirring mechanism (KW ) | 15 | 18.5 | 22 | 30 | 30 | 37< /td> | 45 | ||

| Power of scraping mechanism (KW) | 1.5 | 1.5< /td> | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | ||

| Outline Dimensions | Length (mm) | 3 slots | 6785 | 7685 | 8200 | 9494 | 10200 | 10970 | 12260 | < /tr>

| 4 slots | 8690 | 9890 | 10555 | 12254 | 13205 | 14175 | 15715 | ||

| 5 slots | 10595 | 12095< /td> | 12910 | 15014 | 16210 | 17380 | 18170 | ||

| Width (mm) | 2150 | 2450 | 2750 | 3120 | 3270 | 3450 | 3700 | ||

| Height (mm) | 2758< /td> | 2806 | 2956 | 3250 | 3310 | 3433 | 3503 | ||