15311826613

Click to add WeChatRutile is an important raw material for titanium production. Most of my country's rutile resources are low-grade primary ore resources with fine-grained distribution. The TiO2 content is generally 2% to 4%. The ore dressing process is usually complicated. Flotation is often used as the main separation method in ore dressing. In the flotation process, the selection of agents is particularly important. The following article will focus on the types of rutile flotation agents.

Common collectors for rutile flotation include fatty acids, phosphonic acids, arsenic acids and hydroxamic acids.

Fatty acid collectors: Such as oleic acid, linoleic acid, etc., are commonly used collectors for flotation of oxidized ores such as rutile. The outstanding advantage is good collection performance, but the selectivity is not ideal.

Phosphonic acid collectors: There are styrenephosphonic acid, alkylamine dimethyl bisphosphonic acid, etc., which are a type of collector with good selectivity but high synthesis cost in rutile flotation collectors. Its collection capacity gradually increases with the increase of hydrocarbon carbon atoms. Among them, styrenephosphonic acid has low toxicity, good selectivity, strong collection ability, and is suitable for pulp with a wide pH range. However, it also has strong collection ability for calcium-containing minerals, and is expensive and corrosive to equipment, so it is rarely used in China; alkylamine dimethylphosphonic acid is an amphoteric compound with strong collection performance, strong selectivity, low dosage of reagents, and low price. Therefore, alkylamine dimethylphosphonic acid is more suitable as a collector for rutile flotation.

Arsinic acid collector: Mainly uses benzyl arsenic acid, which is a type of collector with good selectivity but toxicity in rutile flotation collectors. Due to the toxicity of this type of collector, a composite collector containing arsenic acid is usually used to reduce the use of arsenic acid collectors.

Hydroxamic acid collector: Good selectivity, low toxicity, but high cost. Mainly salicylic acid and alkyl hydroxamic acid, among which alkyl hydroxamic acid belongs to chelating agent collector, which is slightly less selective than benzyl arsenic acid and styrene phosphonic acid, but has strong collecting ability, and salicylic acid has certain foaming property. When combined with Pb to float rutile, it can significantly reduce the amount of collector while improving the recovery rate of rutile, saving costs.

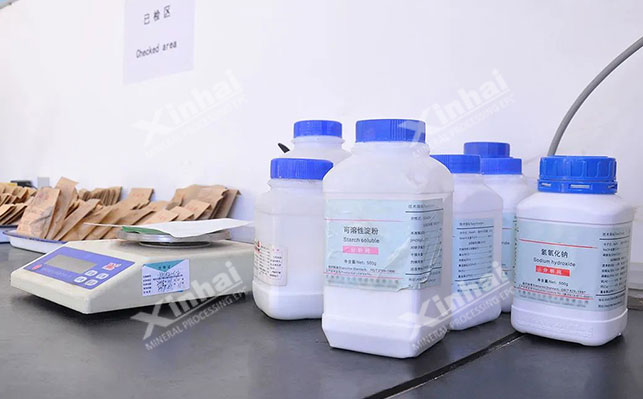

The adjusters used in rutile flotation are mainly activators and inhibitors.

Activator:Lead nitrate is a commonly used activator for rutile flotation. It has a strong activation effect on rutile and also has a strong activation effect on suppressed rutile.

Inhibitor:Common inhibitors include aluminum sulfate, sodium hexametaphosphate, sodium fluorosilicate, dextrin, carboxymethyl cellulose (sodium), etc. Among them, aluminum sulfate can make the surface strongly hydrophilic and unable to react with anionic collectors, so it can inhibit the flotation of rutile; sodium hexametaphosphate, as a commonly used dispersant, can effectively inhibit gangue minerals such as carbonates, quartz, and silicates; sodium fluorosilicate is a widely used inhibitor that can inhibit gangue minerals such as quartz, feldspar, and garnet, and can adjust the pH value of the slurry, but it is toxic itself; dextrin is formed by starch hydrolysis and has similar properties to starch, and can be used as an inhibitor for rutile flotation; carboxymethyl cellulose (sodium) can be used as an inhibitor for calcium-containing minerals or magnesium-containing silicate minerals such as calcite, dolomite, chlorite, apatite, and serpentine.

The above are the types of reagents commonly used in rutile beneficiation. In actual beneficiation plants, the type of rutile ore dressing reagent should be selected according to the properties of the ore. Each type of rutile mineral is different. Therefore, it is recommended to conduct beneficiation tests, design suitable rutile beneficiation processes through test analysis, and determine the appropriate reagent type and dosage according to the process type to improve the gold ore beneficiation efficiency.