Xinhai Vacuum Filter include disc vacuum filters, ceramic filters and permanent magnet vacuum filters. The specific application depends on the mineral processing conditions.

[Processing capacity]: 6~108t/h

[Moisture content of filter cake]: 5~15% or 8~11%

[Application environment]:Disk vacuum filter is suitable for processing suspension filtration and dehydration; permanent magnet vacuum filter is suitable for processing dehydration of coarse particles with strong magnetic minerals; ceramic filter is suitable for concentrates and tailings of various metal and non-metal minerals Dehydration.

15311826613

Click to add WeChatThe filter equipment produced by Xinhai uses microporous ceramics as filter media, saving more than 90% of energy consumption.

Ceramic vacuum filter: Its vacuum degree is 0.09~0.098MPa, the filter cake moisture is low; the added solid content is<50ppm, it can be used repeatedly and reduces emissions; it is equipped with PLC and microcomputer combined with automatic valves Control, high degree of automation, reduce labor intensity; can handle material fineness from -200 to -450 mesh and various ultra-fine materials;

Disc vacuum filter:Motor It adopts a cycloid pinwheel reducer worm gear transmission device, which is easy to use, has high efficiency, low noise and low energy consumption; the filter plate is made of polypropylene plastic material, which is light weight and corrosion-resistant; in addition, the transmission mechanism can be adjusted steplessly. speed, change the spindle speed as needed.

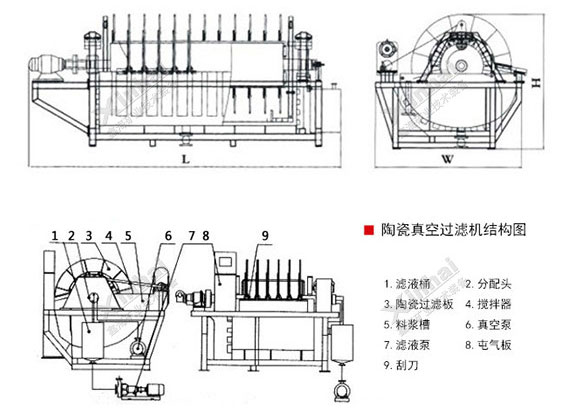

The ceramic vacuum filter mainly consists of a roller system, a stirring system, a supply and discharge system, a vacuum system, a filtrate discharge system, a scraping system, a hair flushing system, a joint cleaning system, a fully automatic control system, a tank, and a rack. Made up of several parts.

The filter disc of the filter rotates slowly in the slurry tank. With the help of the pressure difference formed by the vacuum pump, the solid particles are adsorbed on the filter cloth of the disc to form a filter cake of a certain thickness. The filtrate passes through the filter cake and filter cloth and is discharged from the central axis. The filter cake falls into the filter cake unloading tank under the action of the pressure wind generated by the scraper and the blower.

| Model | filter area/m2 | Filter disc/ring | Number of filter plates/block | Tank volume/m3 | Installed power/KW | Operating power/Kw | Host (L×W×H)/m |

| TC-1 | 1 | 1 | 12 | 0.21 | 3.5 | 2.0 | 1.6×1.4×1.5 |

| TC-4 | 4 | 2 | 24 | 1.0 | 7.0 | 3.0 | 2.4×2.5×2.1 |

| TC-6 | 6 | 2 | 24 | 1.2 | 7.0 | 6.0 | 2.4×2.9×2.5 |

| TC-9 | 9 | 3 | 36 | 1.7 | 9.0 | 7.0 | 2.7×2.9×2.5 |

| TC-12 | 12 | 4 | 48 | 2.2 | 11.0 | 7.5 | 3.0×2.9×2.5 |

| TC-15 | 15 | 5 | 60 | 2.7 | 11.5 | 8.0 | 3.3×3.0×2.5 |

| TC-21 | 21 | 7 | 84 | 4.0 | 13.5 | 9.0 | 4.6×3.0×2.6 |

| TC-24 | 24 | 8 | 96 | 4.5 | 16.5 | 10.5 | 4.9×3.0×2.6 |

| TC-27 | 27 | 9 | 108 | 5.0 | 17.0 | 11.0 | 5.2×3.0×2.6 |

| TC-30 | 30 | 10 | 120 | 5.5 | 17.5 | 11.5 | 5.5×3.0×2.6 |

| TC-36 | 36 | 12 | 144 | 7.0 | 23.0 | 16.0 | 6.6×3.0×2.6 |

| TC-45 | 45 | 15 | 180 | 8.5 | 25.0 | 19.0 | 7.5×3.0×2.6 |

| TC-60 | 60 | 15 | 180 | 12.5 | 33.0 | 22.0 | 7.5×3.3×3.0 |

| TC-80 | 80 | 20 | 240 | 16.2 | 40.0 | 24.0 | 9.0×3.3×3.0 |

| TC-102 | 102 | 17 | 204 | 18.5 | 53.0 | 35.0 | 8.8×3.6×3.3 |

| TC-120 | 120 | 20 | 240 | 20 | 60.0 | 40.0 | 9.7×3.6×3.3 |

| TC-150 | 150 | 25 | 300 | 24 | 75.0 | 47.0 | 11.2×3.6×3.3 |