15311826613

Click to add WeChatSf type flotation machine is a type of mechanical agitation flotation machine. It is an air self-priming flotation machine and mainly relies on Mechanical agitator (rotated from and stator) is used to aerate and stir the slurry. The SF flotation machine can be self-priming and self-priming. It is widely used in the separation of non-ferrous metals, ferrous metals, and non-metallic minerals. .

Nowadays, flotation machines occupy a very large share of the mechanical equipment market. Competing companies not only have to fight price wars, but also have to follow the large-scale and automated machinery. , Energy-saving development, continuous research and development of innovative new equipment to improve the overall performance of the flotation machine.

Xinhai Mining has been producing and developing flotation machines for more than 20 years. Not only is its price more in line with market conditions, but in terms of equipment innovation, in addition to optimizing details, it will also develop high-added products based on customer needs. flotation machine equipment. Xinhai's SF flotation machine has been greatly upgraded in terms of details and customization. Let's take a look at it together

In order to efficiently complete the flotation operation while saving energy and reducing consumption, Xinhai Mining has designed the flotation machine in many details.

1. Increase the gap between the flotation machine impeller and the cover plate, so that the friction between the impeller, cover plate and other components will reduce the impact on the air suction volume of the flotation machine, which not only improves The suction volume is reduced, thereby reducing energy consumption and noise, achieving the purpose of stable production.

2. The forward-inclined tank design basically eliminates the dead spots in the flotation machine tank, speeding up the movement speed of the foam, and effectively improving the flotation efficiency.

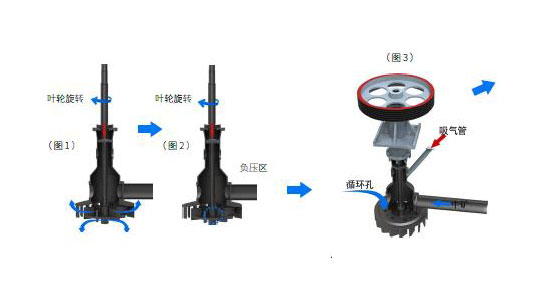

3. The backward-inclined double-sided blade impeller design can realize double circulation in the slurry. During the actual working process, while the impeller rotates, the slurry in the upper and lower impeller cavities is thrown out by centrifugal force, causing negative pressure to form in the upper and lower impeller cavities, thereby achieving the purpose of flotation and separation.

4. Similarly, the design of the backward-inclined double-sided blade impeller makes the slurry thrown out of the lower impeller cavity denser than the three-phase mixture thrown out by the upper blade, so the centrifugal force is greater, which eases the movement. The speed weakening phenomenon creates additional driving force for the three-phase mixture thrown out by the upper blade, and also increases the centrifugal force of the upper impeller cavity, which increases the vacuum degree in the upper impeller cavity and plays a good assisting role.

5. The special process design allows the slurry in the tank to circulate up and down in a fixed manner. This design is conducive to mineral suspension.

1. The impeller of the sf flotation machine can play two roles, one is to inhale sufficient air to mix with the slurry, and the other is to inhale sufficient air to mix with the slurry; It stirs the slurry to fully mix it with the agent, and at the same time, refines the foam. The foam in the flotation cell will adhere to the bubbles, and as the bubbles float to the surface of the slurry, mineralized foam will be formed.

2. The gate height of the flotation machine is adjustable, making it more convenient and flexible to control the liquid level, so that useful foam can be hung out by the scraper to improve the sorting operation.

3. The rubber lining in the flotation machine tank can be selected according to user needs. The anti-corrosion and wear-resistant effect is more than twice that of other materials, which can effectively extend the life of the flotation machine.

4. It can be configured horizontally with the jjf flotation machine, thus eliminating the need for a foam pump and reducing investment costs.

This is Xinhai's innovative SF flotation machine equipment. Not only in research and development, Xinhai has the courage to innovate. In the design of the mineral processing plant, Xinhai Research Institute can also customize flotation process plans and mineral processing plant construction plans that meet actual conditions according to user needs. In addition, Xinhai's packaging and shipping department and installation and debugging team can help users solve equipment packaging and shipping problems and mineral processing on-site equipment installation and debugging problems, helping you solve problems in the end and avoid various problems in the mineral processing plant.